Racket with injection-molded handle

A handle and racket technology, applied in the field of rackets, can solve the problems of increasing the burden on athletes, reducing the weight of the handle of the racket, and easy sweating, etc., to achieve the effects of reducing the risk of breakage, good sports experience, and improving grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

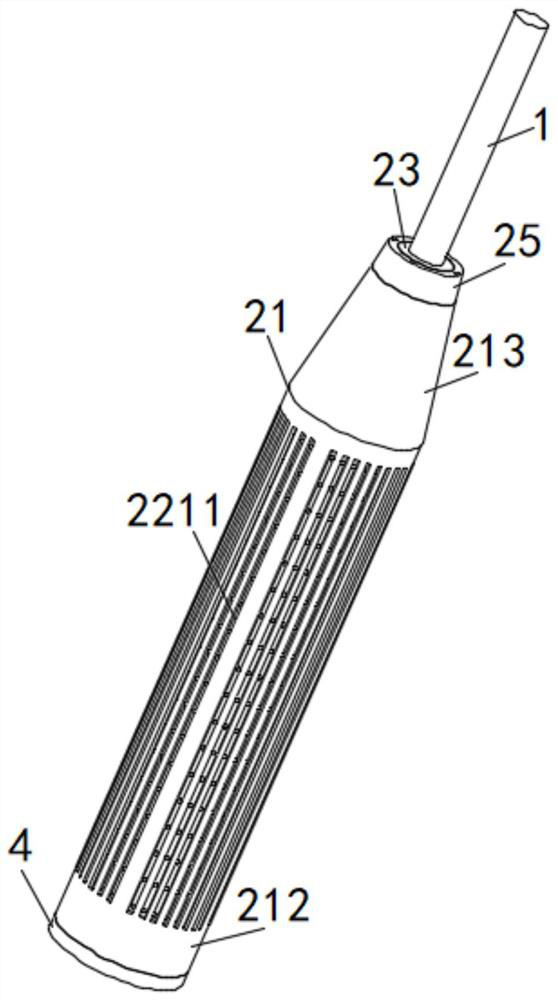

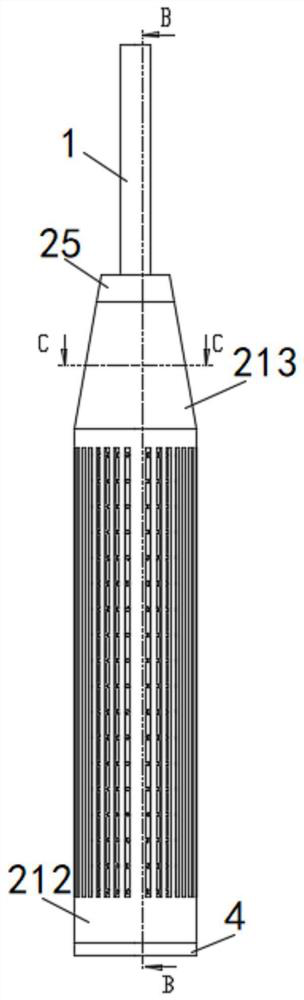

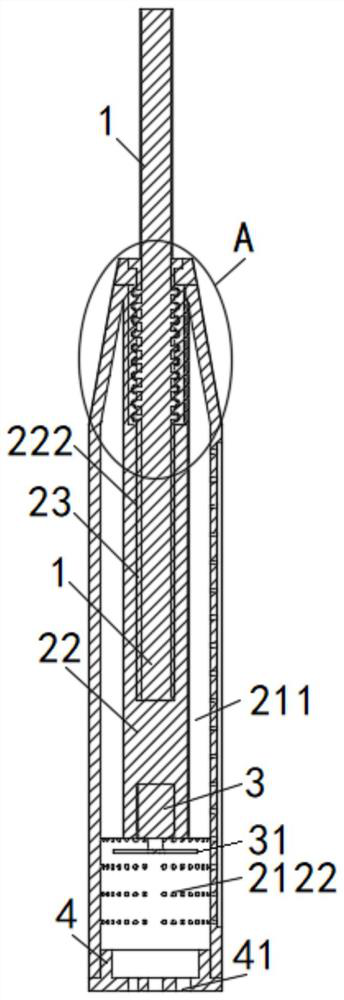

[0034] like Figure 1 to Figure 10 As shown, the present invention provides a racket with an injection-molded handle, including a handle assembly and a middle shaft 1 connected to the racket body, the middle shaft 1 is connected to the handle assembly, and the handle assembly includes an injection-molded handle body, a buffer sleeve 23, and a split sleeve 24 and cover 25; the injection molded handle body includes an outer shell 21 and an inner rod 22; the outer surface of the inner rod 22 is connected to the inner surface of the outer shell 21 through a number of annular evenly distributed connecting ribs 211; the inner side of one end of the outer shell 21 is connected to the inner rod One end of 22 is connected to the outer side; one end of the inner rod 22 is provided with a sleeve installation groove 221; the bottom surface of the sleeve limit groove 221 is provided with a middle rod installation groove 222; 221 connected T-shaped hole 251, here, the cover 25 is fixedly co...

Embodiment 2

[0039] see figure 2 , image 3 as well as Figure 8 As shown, on the basis of Embodiment 1, the outer casing 21 includes a straight pipe section 212 and a cone-like section 213 connected to each other; the cone-like section 213 and the cover 25 are both frusto-conical; the outer surface of the cone-like section 213 and The outer surface of the cover 25 is on the same conical surface to ensure the streamline of the outer shell 21, reduce the wind resistance and improve the aesthetic effect; the outer shell 21, the inner rod 22 and the connecting rib 211 are integrally formed by injection molding.

[0040] In order to increase the friction between the athlete's hand and the outer shell 21, the outer surface of the straight pipe section 212 is located between two adjacent connecting ribs 211 and evenly distributed in a circular manner with several strip-shaped anti-slip grooves 2121, through which several strip-shaped anti-slip grooves 2121 improve friction and improve grip fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com