Nanofiber membrane for skin wound and preparation method thereof

A nanofibrous membrane and nanozyme technology, applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve problems such as inability to effectively inhibit scars, and achieve the effect of promoting rapid healing, inhibiting wound inflammation, and inhibiting tissue inflammation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

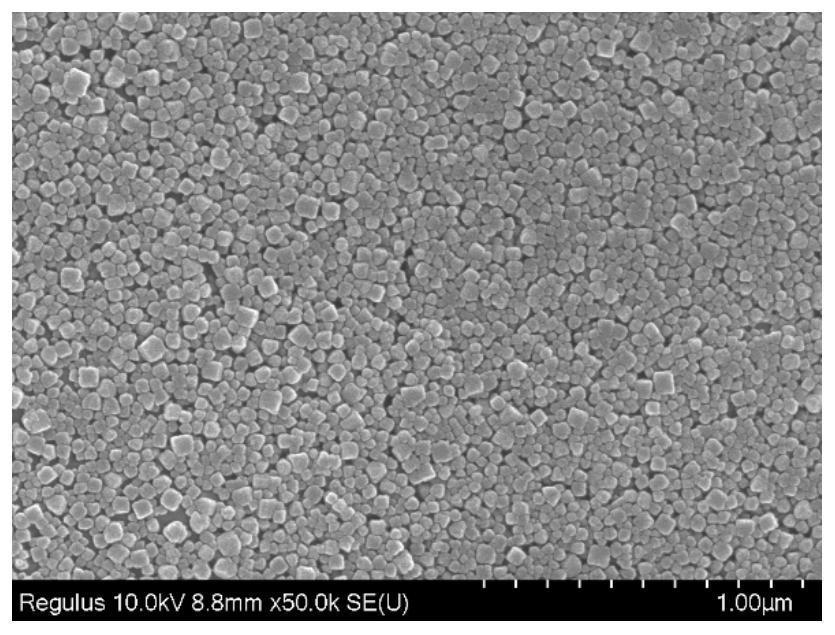

Image

Examples

Embodiment 1

[0029] (1) The preparation by solvothermal reaction is as follows: respectively configure ferric chloride solution and zinc acetate solution with a concentration of 5mM, and then mix 1mL with 2mM polyvinylpyrrolidone of 28mg / mL, and take 2mL of 5mM polyvinylpyrrolidone K 4 [Fe(CN) 6 ] solution was slowly added to the above mixed solution, and reacted for 10 minutes at a temperature of 50° C. to obtain Prussian blue analogues (PBAs). Wash by centrifugation at a rotational speed of 20,000 r / min, and then freeze-dry to obtain the PBAs powder product.

[0030] (2) Dissolve 10mL of 5nM PBAs and 10mL of 5uM AOND in 25°C and stir for 8 hours, then centrifuge and wash with deionized water at a speed of 20000r / min, freeze-dry, and obtain the PBAs / AOND nano Enzyme composites. (3) Gelatin is dissolved in hexafluoroisopropanol to obtain a gelatin solution with a mass fraction of 8% as a shell solution; polycaprolactone is dissolved in hexafluoroisopropanol to obtain a mass fraction of ...

Embodiment 2

[0033] (1) Preparation by solvothermal reaction is specifically: ferric chloride and zinc acetate at a molar ratio of 2:1, both at a concentration of 8mM, taking 2mL and 1mL respectively, and mixing them with 3mL of 28mg / mL polyvinylpyrrolidone evenly, taking 3 mL of 5 mM K 4 [Fe(CN) 6 ] solution was slowly added to the above mixed solution, and reacted for 30 minutes at a temperature of 70° C. to obtain Prussian blue analogues (PBAs). Wash by centrifugation at a rotational speed of 15000r / min, and then freeze-dry to obtain the PBAs powder product.

[0034] (2) Dissolve 10mL of 5nM PBAs and 10mL of 5uM AOND obtained in step a and stir at 25°C for 10 hours, then centrifuge and wash with deionized water at a speed of 15000r / min, and freeze-dry to obtain the PBAs / AOND nanozyme composite material.

[0035] (3) Gelatin is dissolved in hexafluoroisopropanol to obtain a gelatin solution with a mass fraction of 12% as a shell solution; polycaprolactone is dissolved in hexafluoroi...

Embodiment 3

[0038](1) Preparation by solvothermal reaction is specifically: ferric chloride, zinc acetate, the concentration is 5mM, each take 1mL, and mix with 28mg / mL polyvinylpyrrolidone 3mL, take 2mL of 5mM concentration of K 4 [Fe(CN) 6 ] solution was slowly added to the above mixed solution, and reacted for 30 minutes at a temperature of 70° C. to obtain Prussian blue analogues (PBAs). Wash by centrifugation at a rotational speed of 15000r / min, and then freeze-dry to obtain the PBAs powder product.

[0039] (2) Gelatin is dissolved in hexafluoroisopropanol to obtain a gelatin solution with a mass fraction of 8% as a shell solution; polycaprolactone is dissolved in hexafluoroisopropanol to obtain a mass fraction of 10% polycaprolactone solution, and then 0.1 mg of PBANPs was added to obtain a nuclear solution; under the conditions of a temperature of 20° C. and a humidity of 40%, the nanofibrous membrane was prepared under the regulated spinning process. Co-spun to obtain PCL / AOND-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com