Spent fuel dissolver critical safety analysis method considering fuel assembly burnup distribution

A criticality safety and fuel assembly technology, applied in the direction of reactor fuel elements, reactors, and greenhouse gas reduction, can solve the problems of not providing criticality safety analysis methods, maximize comprehensive benefits, increase processing capacity, and solve safety and economic problems The contradictory effect of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

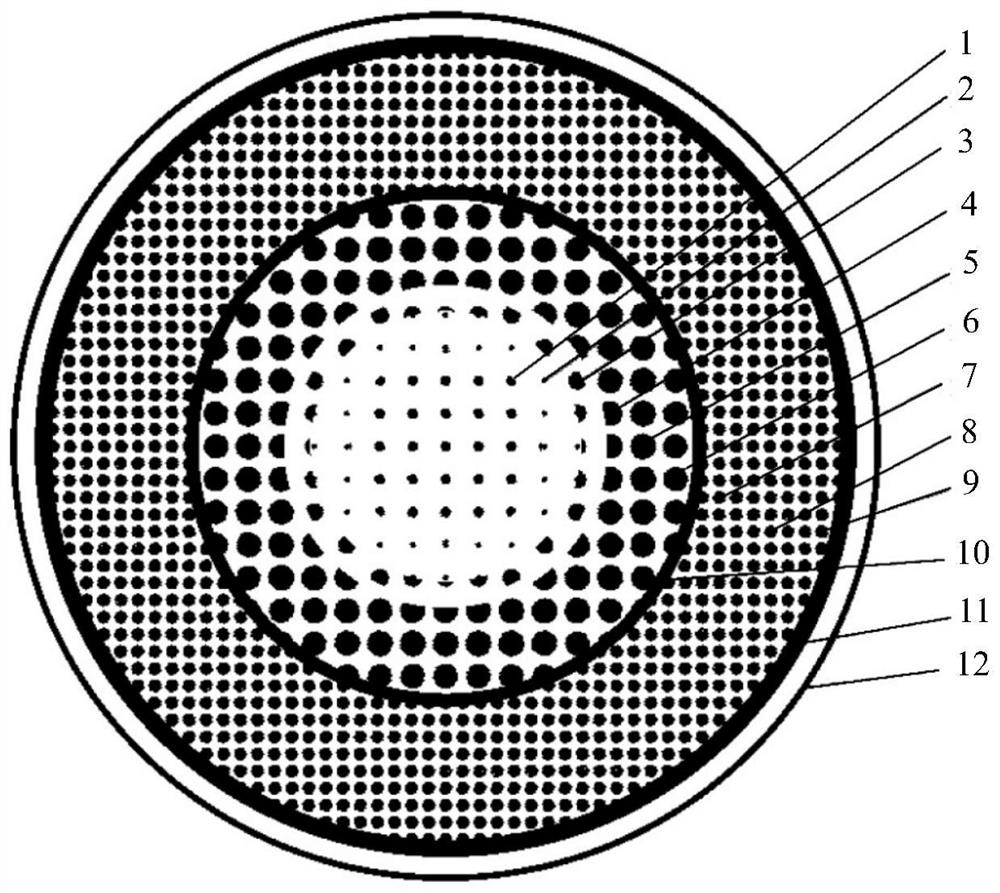

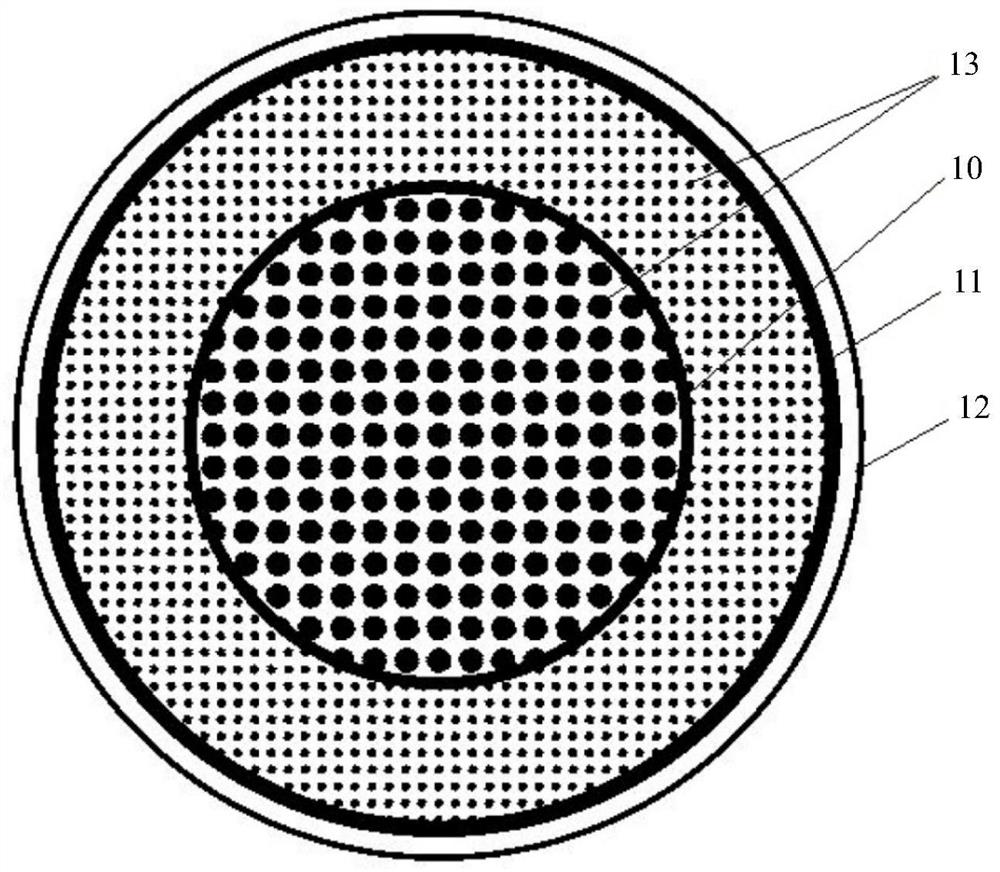

[0051] Taking a spent fuel dissolver as an example, how the present invention is applied to criticality safety analysis of spent fuel dissolver is described. The most reactive spent fuel assembly to be processed by the spent fuel dissolver is a 17×17 assembly, which is divided into 18 sections in the axial direction, 235 The U enrichment degree is 4.95%, and its average fuel consumption is 38200MWd / tU. The mass of fuel pellets processed in the spent fuel dissolver is the mass of a whole PWR spent fuel assembly.

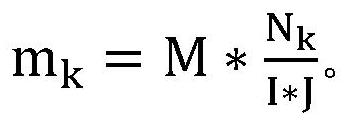

[0052] First, for the most reactive spent fuel assembly, the number of radial fuel rods is 264, and the number of axial segments is 18. The normalized relative distribution of burnup in each section of the envelope in the axial direction calculated by the component burnup calculation program is shown in Table 1, and the normalized relative distribution of burnup in each fuel rod in the radial direction is shown in Table 2.

[0053] Table 1

[0054]

[0055]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com