High-overload-resistant projectile for gas detonation driven ultra-high-speed launcher

A launching device and ultra-high-speed technology, applied in the field of ultra-high-speed collision research, can solve the problems of reducing the launch efficiency and service life of the detonation drive system, and achieve the effects of increasing the effective mass ratio, increasing the service life, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

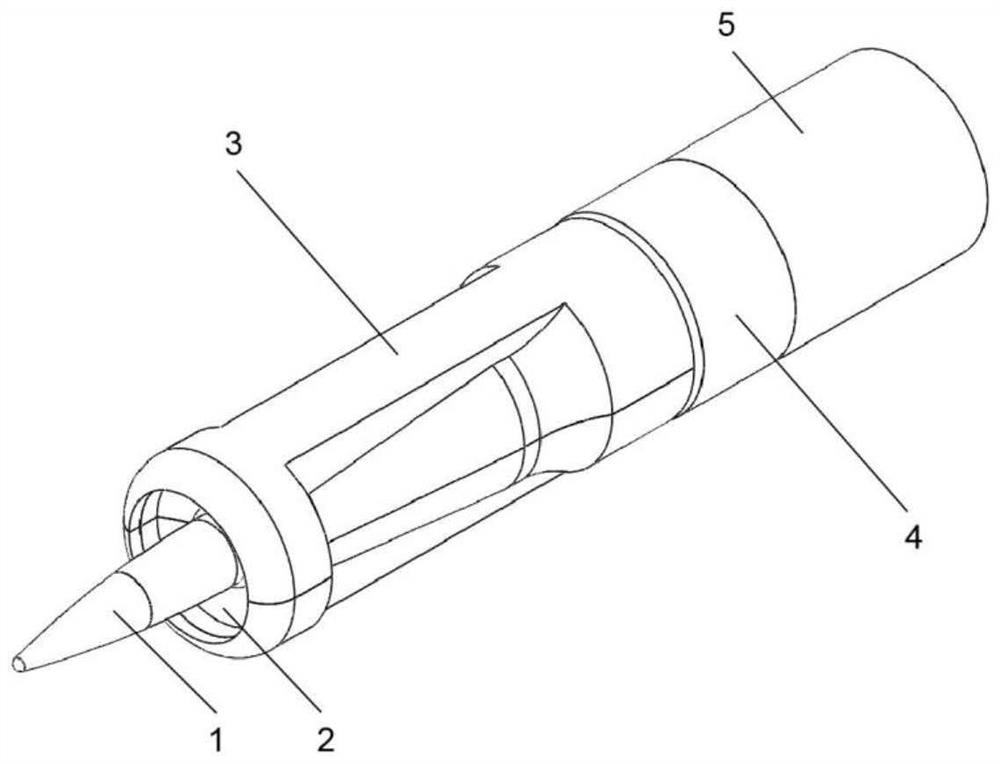

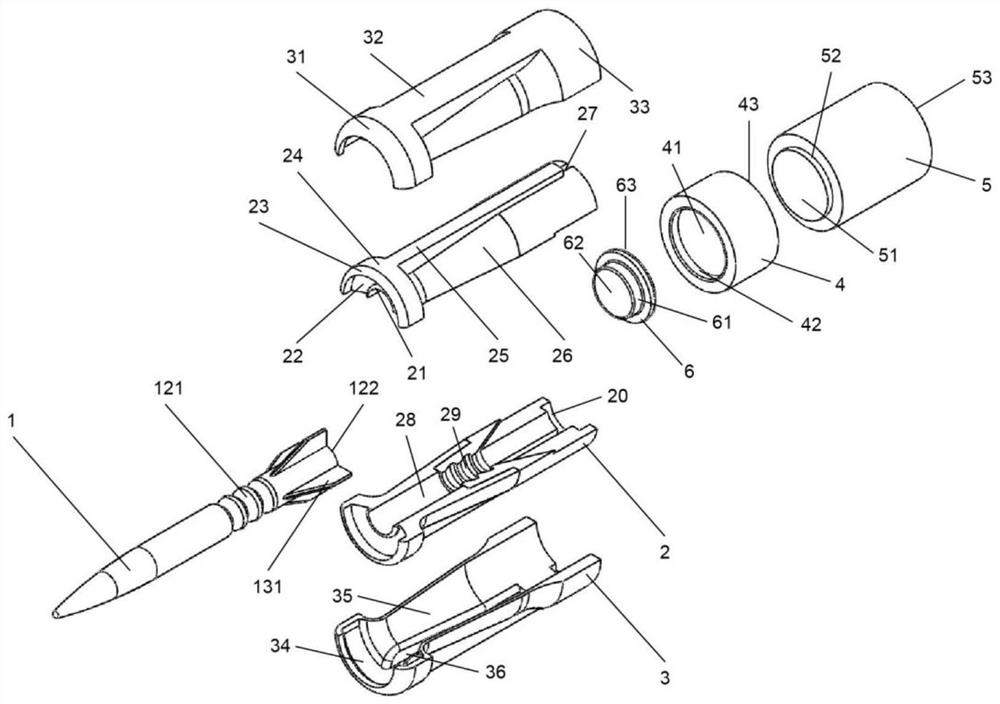

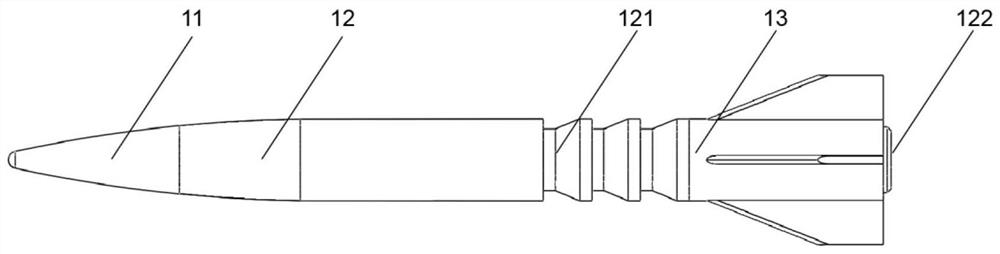

[0034] Such as Figure 1-Figure 4 As shown, the purpose of this invention is to provide a gas detonation-driven ultra-high-speed launcher anti-high overload projectile, which is characterized in that, including flying body 1, combined bullet holder, multi-layer bottom bracket, the combined bullet holder is from the outside An anti-wear bullet holder 3 and an anti-overload bullet holder 2 are sequentially arranged inside, the anti-wear bullet holder 3 is in interference fit with the launch tube, the interior of the anti-wear bullet holder 3 is provided with a housing cavity, and the anti-overload bullet holder 2 is installed in the accommodation type In the cavity, the flying body 1 is installed inside the anti-overload bullet holder 2, and the rear end of the anti-overload bullet holder 2 is combined with the titanium alloy gasket 6 in the multi-layer bottom bracket and inserted into the aluminum alloy bottom bracket 4 of the multi-layer bottom bracket. In, thus forming an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com