A transparent thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastomer technology, applied in the field of thermoplastic elastomers, can solve problems such as improving the mechanical properties of materials, and achieve the effects of improving mechanical properties, superior comprehensive performance, and ensuring transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 105.1 g of diglycolamine was placed in a three-necked flask, and protective nitrogen gas was introduced below the liquid level. Under the condition of 10° C., 67.1 g of 1,1,3,3-tetramethyldisilane was slowly added dropwise within 1.0 hour. After the dropwise addition was completed, the reaction was continued at 10°C for 0.5 hours, then the temperature was raised to 70°C, and the reaction was continued with stirring for 1 hour to obtain 170.2g of 1,3-bis[2-(2-hydroxyethoxy)-ethylamino] Tetramethyldisiloxane.

Embodiment 2

[0022] 147.2g of diglycolamine was placed in a three-necked flask, and protective nitrogen gas was introduced below the liquid level. Under the condition of 5° C., 94.0 g of 1,1,3,3-tetramethyldisilane was slowly added dropwise within 2.5 hours. After the dropwise addition was completed, the reaction was continued at 5°C for 0.5 hours, then the temperature was raised to 73°C, and the reaction was continued with stirring for 1 hour to obtain 238.4g of 1,3-bis[2-(2-hydroxyethoxy)-ethylamino] Tetramethyldisiloxane.

Embodiment 3

[0024] Place 210.3g of diglycolamine in a three-necked flask, and insert protective nitrogen below the liquid level. Under the condition of -15°C, 134.3 g of 1,1,3,3-tetramethyldisilane was slowly added dropwise within 2.8 hours. After the dropwise addition was completed, the reaction was continued at -15°C for 0.5 hours, then the temperature was raised to 65°C, and the reaction was continued with stirring for 1 hour to obtain 340.6g of 1,3-bis[2-(2-hydroxyethoxy)-ethylamino ] Tetramethyldisiloxane.

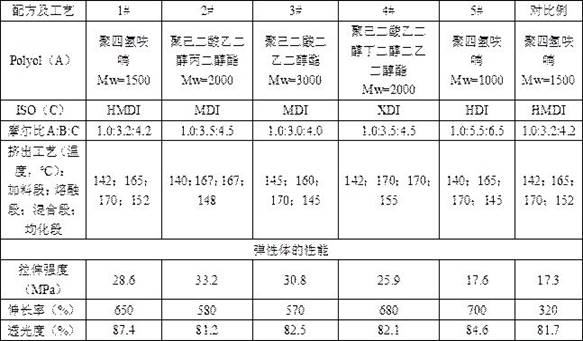

[0025] Using the prepared finished product 1,3-bis[2-(2-hydroxyethoxy)-ethylamino]tetramethyldisiloxane as chain extender (marked as B), adopt twin-screw reactive extrusion process A thermoplastic elastomer was prepared, and the length-to-diameter ratio of the screw was 40:1. A thermoplastic elastomer was prepared using 1,3-bis(4-hydroxybutyl)tetramethylsiloxane as a chain extender as a comparative example. The specific formulation, extrusion process and properties of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com