Preparation process and device of methyltrimethoxysilane

A technology of methyltrimethoxysilane and monomethyltrichlorosilane, which is applied in the field of preparation process and device of methyltrimethoxysilane, can solve the problems of the yield decline of methyltrimethoxysilane and reduce the cost of raw materials and equipment investment cost, reduce the risk of introducing impurity substances, and the effect of uniform liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

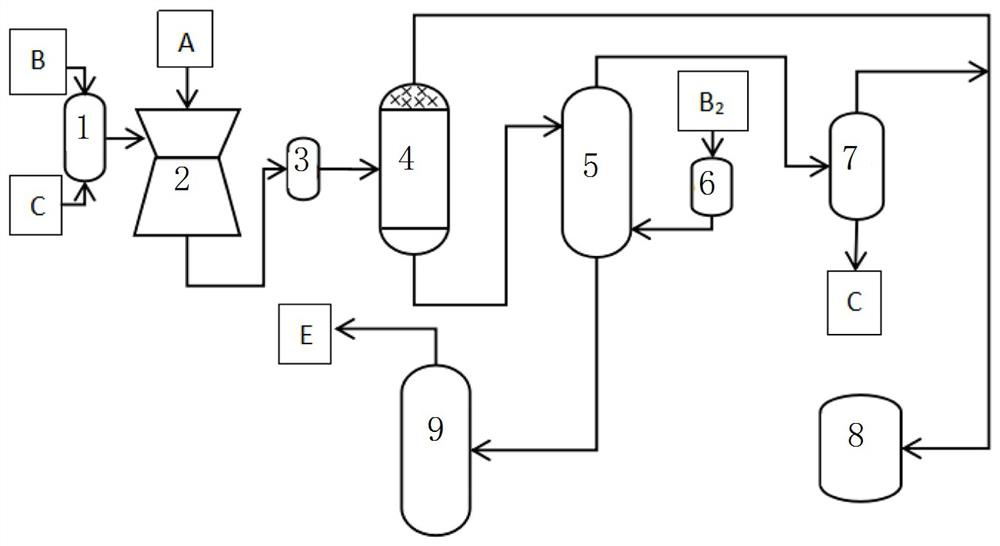

[0029] A preparation device for methyltrimethoxysilane, the mixer 1 is connected to the Venturi mixer 2, the Venturi mixer 2 is connected to the heat exchanger 3, the heat exchanger 3 is connected to the gas-liquid separation tank 4, and the gas-liquid separation The tank 4 is connected to the top of the stripper 5, the bottom of the stripper 5 is connected to the rectification tower 9, the rectification tower 9 is connected to the product tank, and the bottom of the stripper 5 is provided with a connecting pipe of the preheater 6.

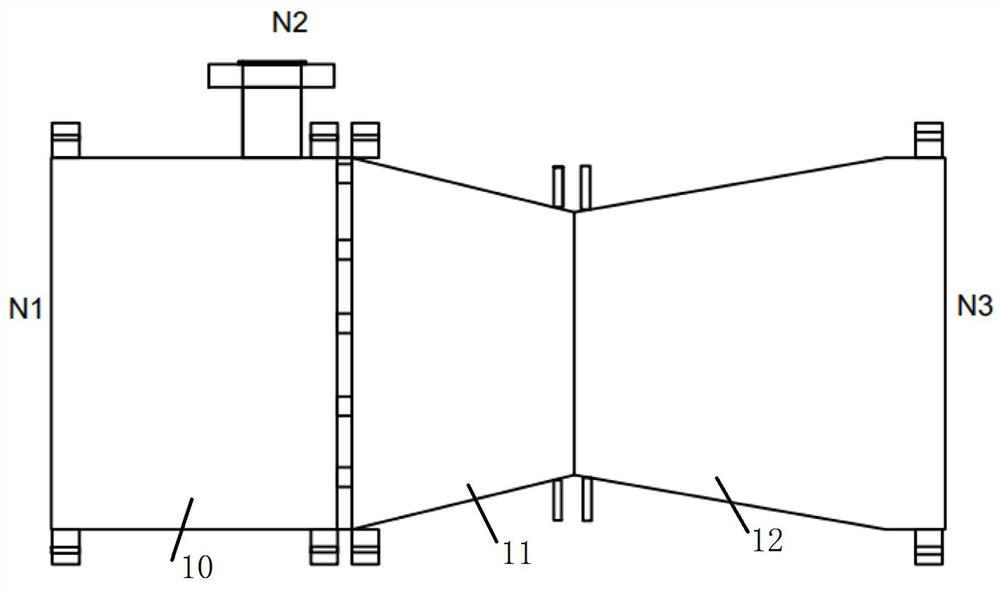

[0030] Three mixing chambers are arranged in the Venturi mixer 2, the second mixing chamber 11 and the third mixing chamber 12

[0031] The joints of the joints are provided with variable-diameter pipes, that is, the diameter of the joints is 200 mm, and the diameter of the feed end of the second mixing chamber 11 and the discharge end of the third mixing chamber 12 is 350 mm; the first mixing chamber 10 and the second mixing chamber A baffle 13 i...

Embodiment 2

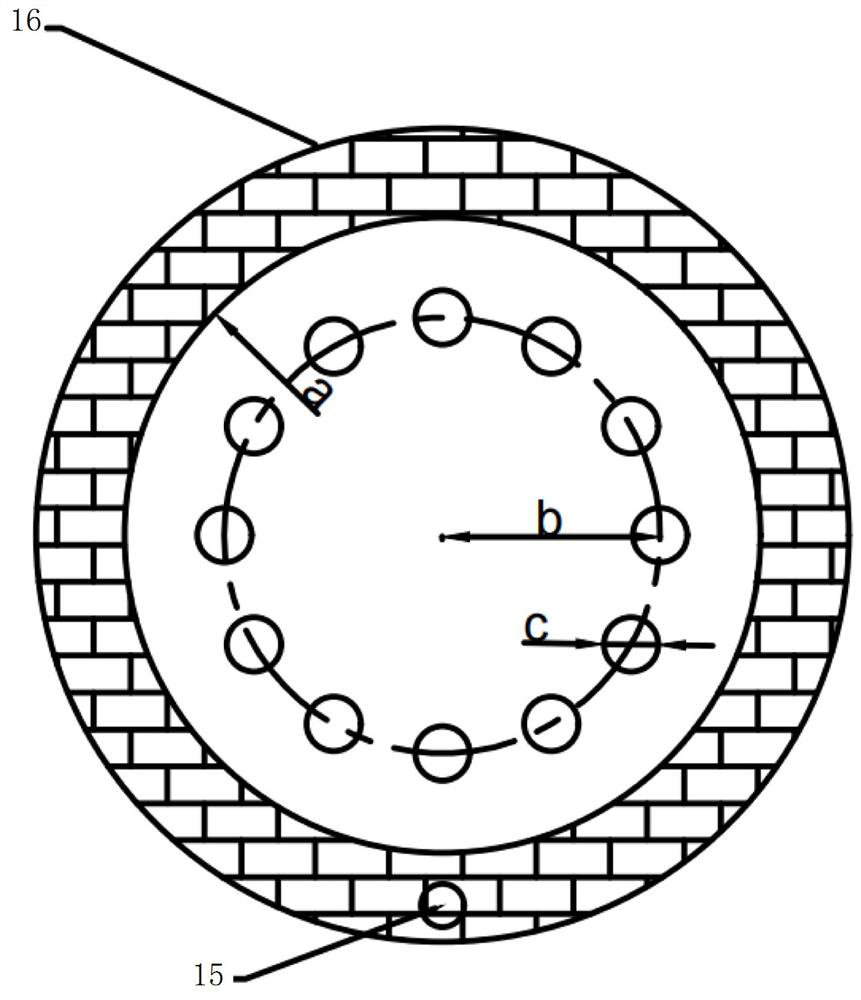

[0035] The process of the present invention that adopts the structure of the Venturi mixer of the above-mentioned embodiment 1 is carried out only in the number of holes in the Venturi mixture, the distance from the holes to the edge of the baffle a, the center of the baffle from the center of the hole b, and the inner diameter of the hole c. adjustments, as follows:

[0036] (1) Prepare monomethyltrichlorosilane A and methanol B with a molar ratio of 1:2.5, monomethyltrichlorosilane A and n-hexane with a mass ratio of 1:0.6 as raw materials, add methanol B and n-hexane to the mixer After mixing evenly, the mixed solution of monomethyltrichlorosilane A and the mixer is simultaneously pumped into the Venturi with internal pressure of 0.2MPa, internal diameter a=300mm, b=80mm, c=25mm, and 12 holes at 25°C for mixing In the container, the two are fully mixed and reacted;

[0037] (2) After the reaction product is exchanged by the heat exchanger, the temperature is kept at 30°C a...

Embodiment 3

[0042] The process of the present invention that adopts the structure of the Venturi mixer of the above-mentioned embodiment 1 is carried out only in the number of holes in the Venturi mixture, the distance from the holes to the edge of the baffle a, the center of the baffle from the center of the hole b, and the inner diameter of the hole c. adjustments, as follows:

[0043] (1) Prepare monomethyltrichlorosilane A and methanol B with a molar ratio of 1:2.6, monomethyltrichlorosilane A and n-hexane with a mass ratio of 1:0.5 as raw materials, and add methanol B and n-hexane to the mixer After mixing evenly, the mixed solution of monomethyltrichlorosilane A and the mixer is simultaneously pumped into the Venturi with internal pressure of 0.2MPa, internal diameter a=350mm, b=90mm, c=30mm, and 12 holes at 25°C for mixing In the container, the two are fully mixed and reacted;

[0044] (2) After the reaction product is exchanged by the heat exchanger, the temperature is kept at 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com