Method and equipment for preparing mine repairing material from river sludge

A technology for repairing materials and river silt, applied in sewage/sludge fertilizers, chemical instruments and methods, applications, etc., can solve problems such as large space occupation, secondary pollution, secondary agglomeration, etc. The effect of reducing evaporation and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further illustrated by the following examples.

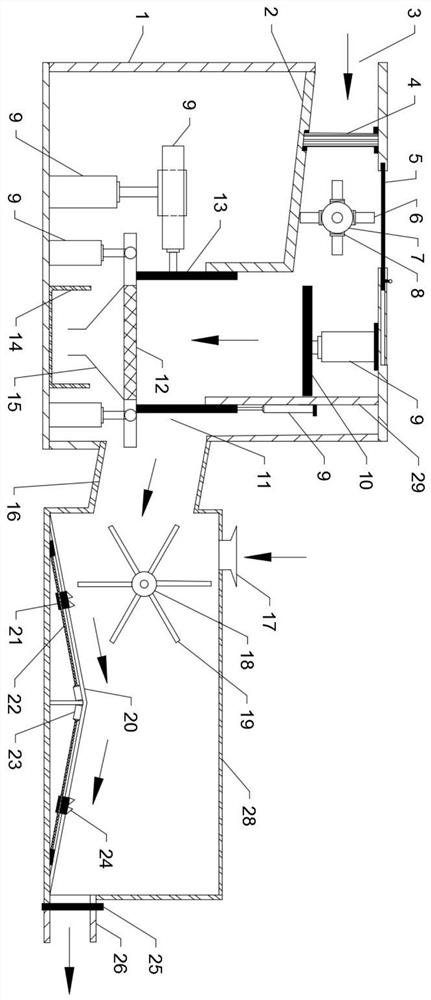

[0037] A method for preparing mine restoration materials from river silt, comprising the following steps:

[0038] A, the making of soil improver: mix 50 parts of sepiolite, 20 parts of chitosan, 20 parts of lime and 10 parts of plant ash according to the mass ratio to get the soil improver;

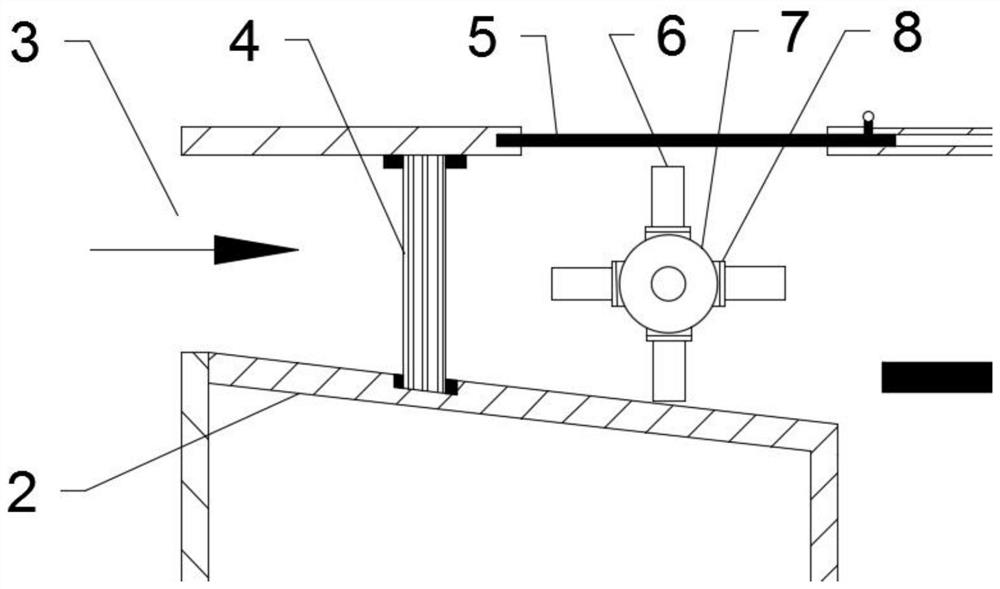

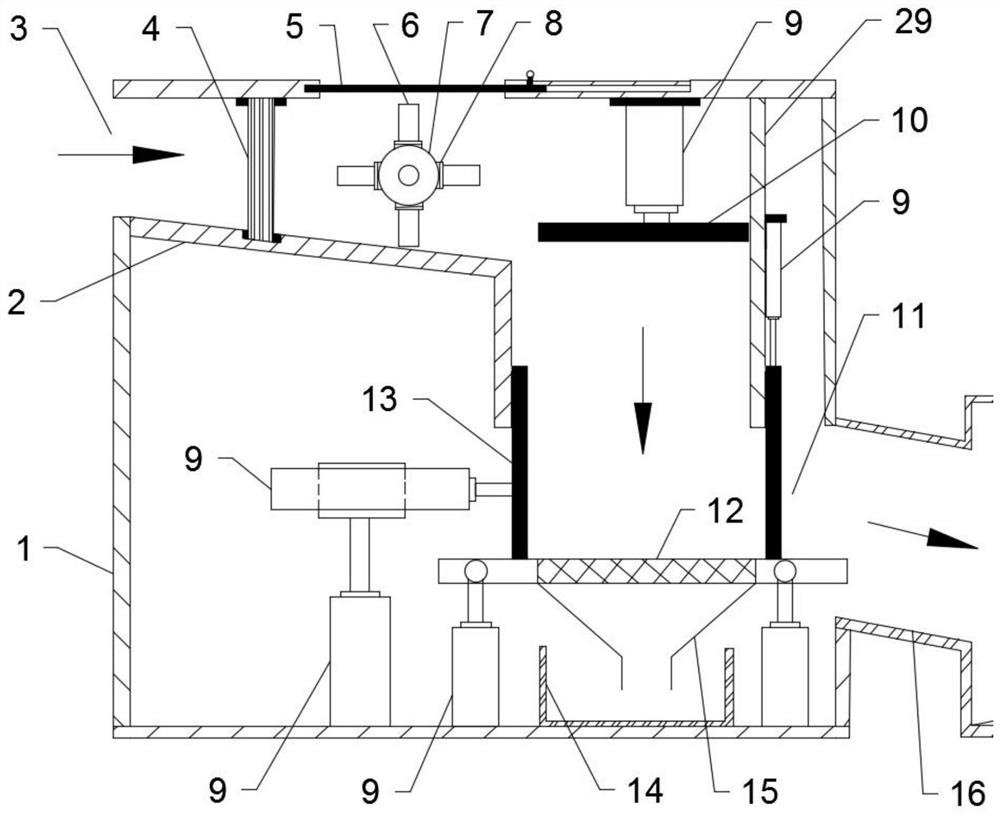

[0039] B. Production of improved silt: ① put the river and lake silt that has been cleared out within 1-3 days into the twin-shaft mixer, and add quicklime with an amount of 0.5%-1% of the silt mass at the same time, and the speed is controlled at 30-40r / min. Stir well, let it stand for 1-2 days, and stir once during the period;

[0040] ②Put the fermented material into the dehydration box 1 of the sludge dehydrator to separate the material from the mud and water. The dehydrated sludge enters the mixing barrel 28 and then adds dry straw powder to mix with it and mix well to form improved sludge;

[0041] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com