Harmless treatment method for oil stain solid waste

A disposal method and oil pollution technology, applied in chemical instruments and methods, sludge treatment, water/sewage multi-stage treatment, etc., can solve the problems of inability to achieve oil resource recovery, inability to achieve treatment effects, and difficult to control secondary pollution, etc. Achieve the effect of eliminating dioxin pollution, using a wide range of materials and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

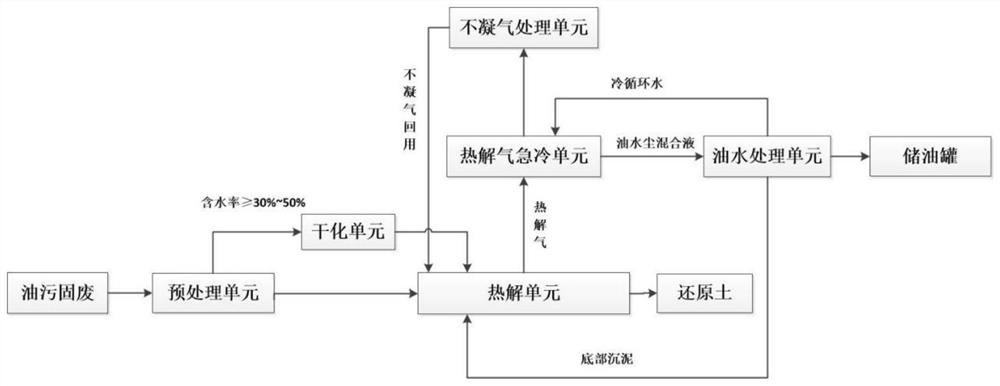

[0033] 1. The oily solid waste is sent to the pretreatment unit, and after being crushed by the crusher, it is sent to the drum sieve for screening, and the inorganic substances with a particle size larger than 8-10mm mixed in the oily solid waste are screened out. If the moisture content is higher than 30%-50%, it will be sent to the drying unit for drying, otherwise it will be directly sent to the pyrolysis unit for pyrolysis, and the oversize will be sent back to the crusher for crushing and then continue to sieve, and so on.

[0034] 2. After sieving, the oil sludge with a moisture content higher than 30%-50% is sent to the drying unit. The drying machine is composed of a hollow paddle and a partition wall cavity, and the steam or heat transfer oil generated by the back-end process is used to indirect Conduction heating oil sludge, composition, wet sludge is conveyed, enters the warehouse body, is stirred by hollow paddles, heat exchanged, after the water is gasified, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com