Roller printing machine

A printing machine and roller technology, applied in the field of roller printing machines, can solve the problems of easy reduction of imprinting accuracy, heating temperature, inaccurate heating time control, and reduced imprinting quality, achieving simple structure, low cost, and improved imprinting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

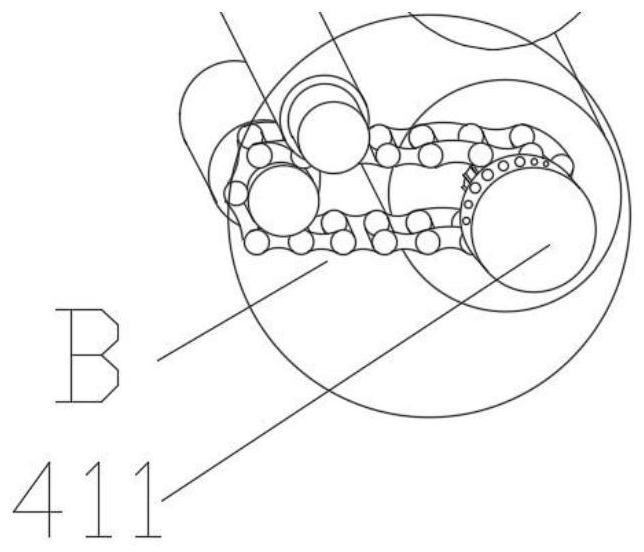

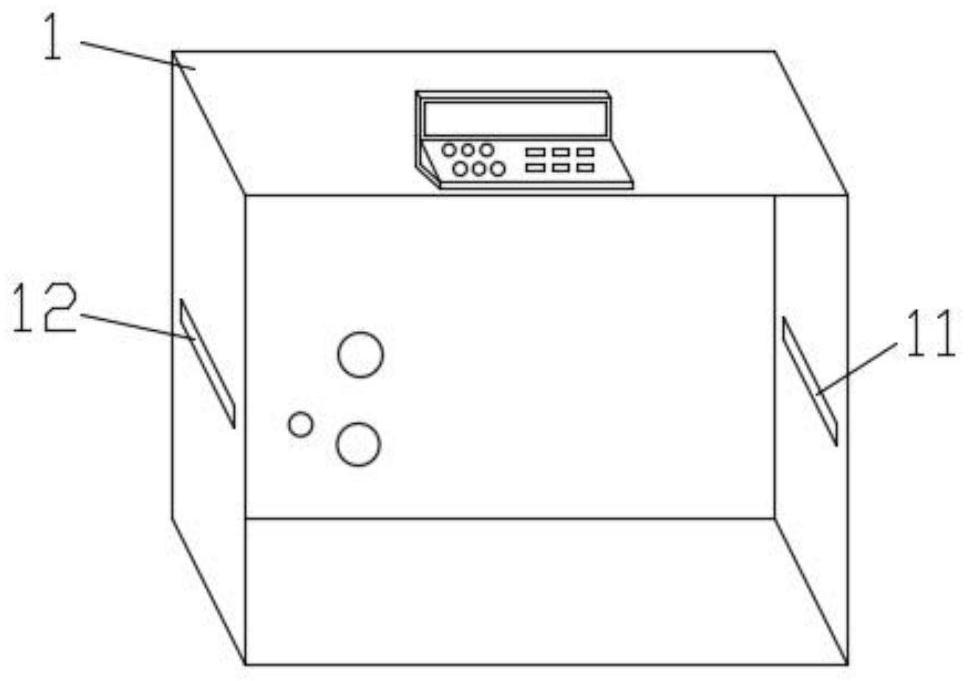

[0028] refer to Figure 1-3 A roll printing machine is shown, comprising: a casing 1, a transmission device 2, a heating device 3, an extrusion device 4, a guide roller 5, and a control device 6; wherein the left and right ends of the casing 1 are respectively provided with an inlet 11 and an outlet 12; The transmission device 2 includes a plurality of conveying rollers 21 and two connecting plates 22, and the two connecting plates 22 are respectively horizontally arranged on the inner walls of the front and rear sides of the housing 1; a plurality of conveying rollers 21 are arranged below the entrance 11, and each conveying roller The two ends of 21 are respectively fixedly connected with two connecting plates 22; the heating device 3 is fixedly connected to the inside of the housing 1, and is arranged above a plurality of conveying rollers 21; the extruding device 4 includes two extruding rollers 41 and two Motor 42, bearings 411 are installed at both ends of the solid gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com