Biomass particle intelligent processing equipment capable of reducing abrasive particle abrasion

A biomass granule, intelligent processing technology, applied in the direction of biofuel, die extrusion granulation, waste fuel, etc., can solve the problems of wear, reduce service life, mix into the sand and gravel roll surface, etc., to avoid excessive temperature, avoid The effect of excessive friction and reduced input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

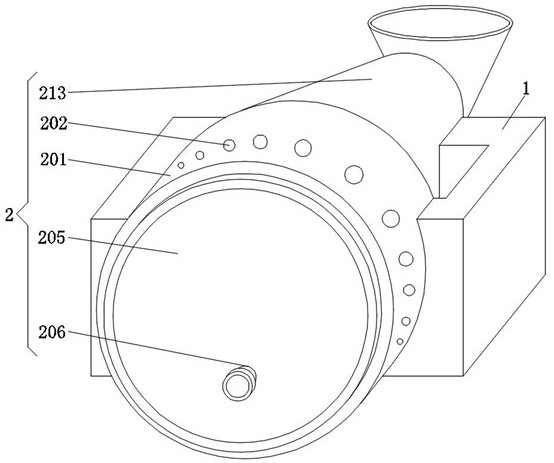

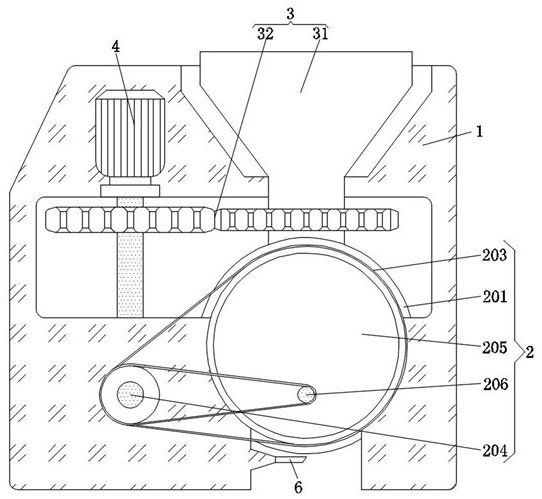

[0028] see figure 1 , 2 , 3, 4, 7 and 8, an intelligent biomass particle processing equipment for reducing abrasive wear, including a forming mechanism 2, the forming mechanism 2 includes a ring die plate 201, and the outer surface of the ring die plate 201 is provided with a ring die hole 202 , the periphery of the front side of the ring die plate 201 is connected with a rotating shaft 1 204 through a belt 203. The front side of the ring die plate 201 is provided with a front baffle plate 205, and the bottom of the front baffle plate 205 is rotatably connected with a pressure roller 206. A column groove 207 is opened on the periphery, and a plug block 208 is connected to the inner limit of the column groove 207. One end of the plug block 208 close to the center of the pressure roller 206 is hinged with a hinge rod 209, and the other end of the hinge rod 209 is hinged with a limit plate 210. The pressure roller The interior of 206 is filled with filling liquid 211, the center...

Embodiment 2

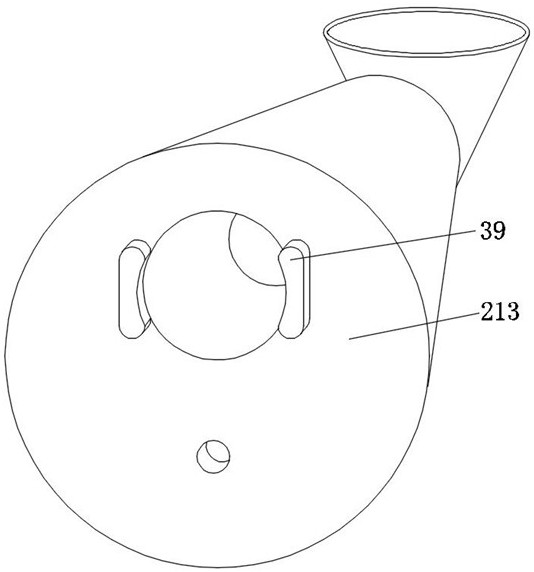

[0030] see Figure 4 , 5, 6 and 9, an intelligent processing equipment for biomass particles that reduces abrasive wear, including an adjustment mechanism 3, the adjustment mechanism 3 includes a turntable 31, the middle of the turntable 31 is driven and connected to a gear set 32, and the top of the turntable 31 is provided with a filter The mouth 33, the left and right sides of the top of the turntable 31 are provided with stepped grooves 34, the middle of the turntable 31 is fixedly connected with an I-shaped rod 35, and the left and right sides of the I-shaped rod 35 are slidably connected with a slider 36, and the middle of the slider 36 is hinged with a The connecting rod group 37, the left and right ends of the turntable 31 are fixedly connected with electromagnets 38, and a thermal sensor assembly 39 is arranged below the turntable 31. A connecting rod group 37 is connected to the top of the shaped rod 35 at an elastic limit, and the left and right ends of the connect...

Embodiment 3

[0032] see Figure 1-9 , an intelligent biomass particle processing equipment for reducing abrasive wear, comprising a frame body 1, the bottom of the frame body 1 is rotatably connected with a forming mechanism 2, the forming mechanism 2 includes a ring die plate 201, and the outer surface of the ring die plate 201 is provided with The ring die hole 202, the periphery of the front side of the ring die plate 201 is connected with a rotating shaft 204 through a belt 203, the front side of the ring die plate 201 is provided with a front baffle plate 205, and the bottom of the front baffle plate 205 is rotatably connected with a pressing roller 206, A column groove 207 is opened on the periphery of the pressure roller 206, and a plug block 208 is connected to the inner limit of the column groove 207. One end of the plug block 208 close to the center of the pressure roller 206 is hinged with a hinge rod 209, and the other end of the hinge rod 209 is hinged with a limit plate 210, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com