Power plant desulfurization tower

A technology for desulfurization towers and power plants, applied in the field of desulfurization towers, can solve the problems of reducing the desulfurization efficiency of desulfurization towers, reducing the content of gypsum, and the dead angle of stirring, so as to achieve the effect of desulfurization, maximize the effect and ensure the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

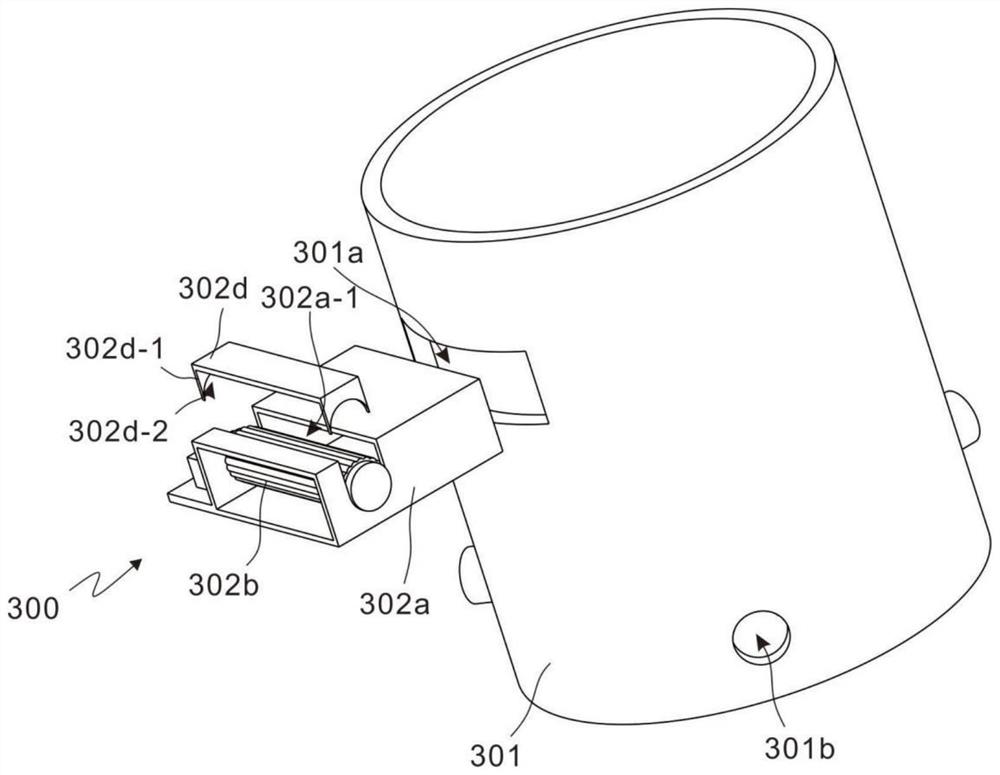

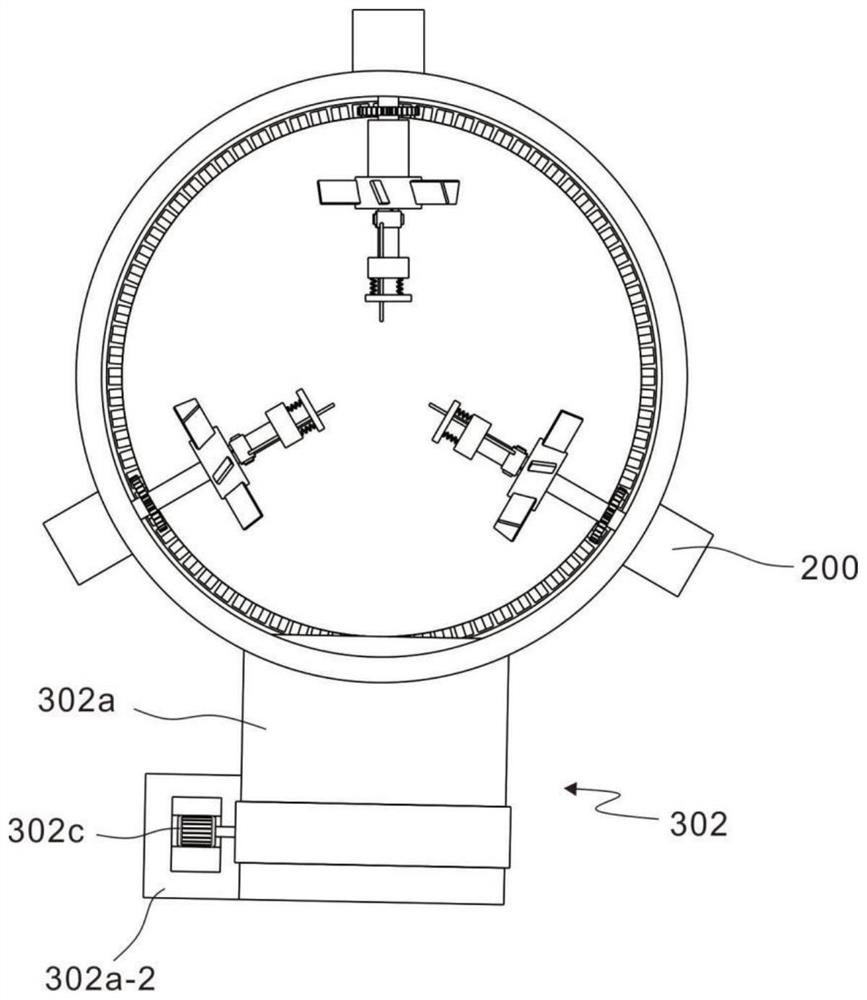

[0032] refer to figure 1 , 2 , is the first embodiment of the present invention, which provides a power plant desulfurization tower, which includes a main module 300 and a stirring module 200 .

[0033] The main module 300 includes a desulfurization tower 301 and a soot feeding body 302. The outer wall of the desulfurization tower 301 is provided with an air supply port 301a, and the soot feeding body 302 is installed at the gas supply port 301a; during the wet desulfurization process, the empty tower spray is mainly used for flue gas desulfurization , the desulfurization liquid circulation method adopts the circulation in the tower, and a pulp pool is set at the bottom of the desulfurization tower; the smoke is usually sent from the dust inlet body 302 into the desulfurization tower 301, and desulfurization is carried out through the device structure and desulfurization liquid inside the desulfurization tower 301, and the clean air is It is discharged from the top of the des...

Embodiment 2

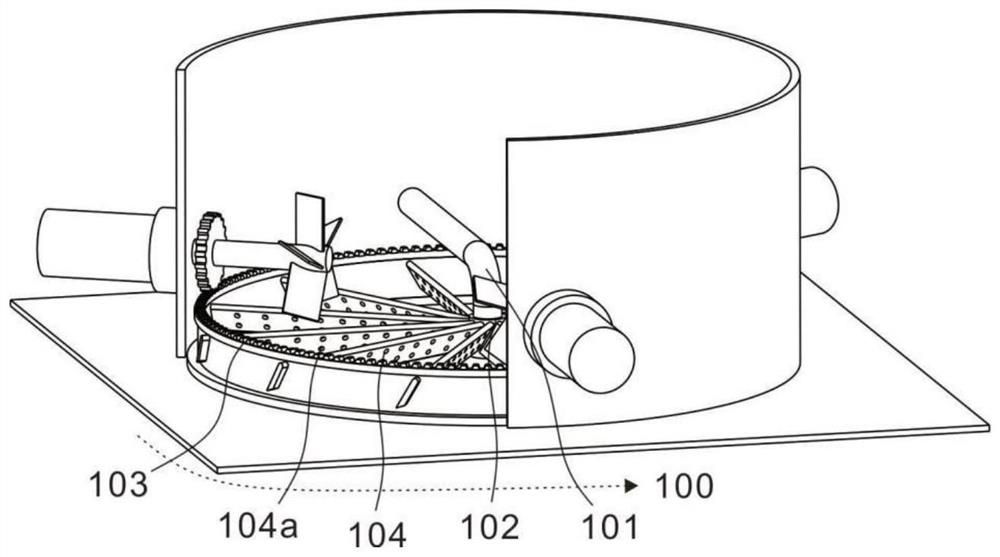

[0041] refer to Figure 3-8, is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and also includes a flushing module 100, the flushing module 100 and the stirring module 200 are installed at the bottom of the desulfurization tower; the flushing module 100 can flush the bottom of the desulfurization tower Scraping, the agitation of the agitation module 200 can reduce gypsum deposits in the slurry tank.

[0042] The flushing module 100 includes a water inlet pipe 101, a shaft pipe 102, a ring gear 103 and a descaling plate 104, the shaft pipe 102 and the ring gear 103 are installed at the bottom of the desulfurization tower, and the shaft pipe 102 is located in the ring gear 103 and is coaxial with the ring gear 103 The center of the arrangement, the descaling board 104 is located between the shaft tube 102 and the ring gear 103, and a plurality of them are arranged on the circumference and fixedly connected to the shaft tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com