Water vapor loop constant pressure control method and device for extracorporeal shock wave machine

An extracorporeal shock wave and constant pressure control technology, applied in electric fluid pressure control, medical science, surgery, etc., can solve problems such as high cost, cumbersome operation, and inability to be used in practice, and achieve accurate pressure conduction, electrical Simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

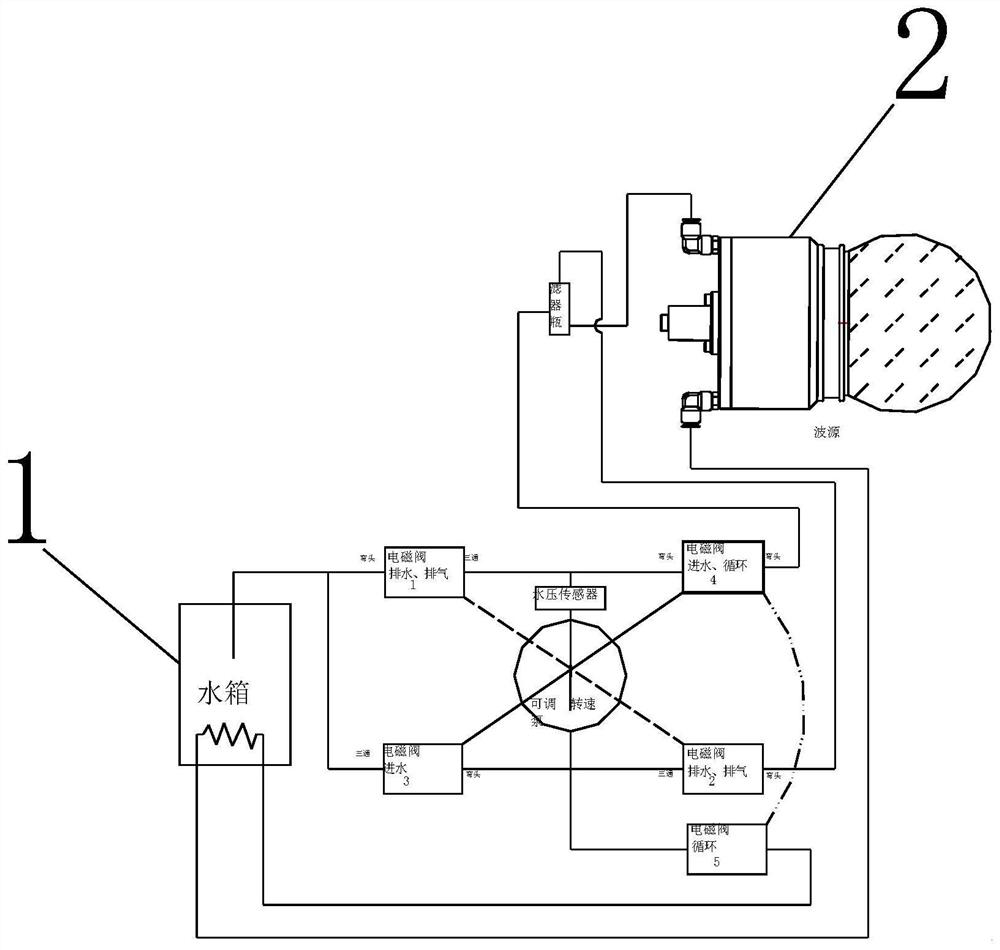

Method used

Image

Examples

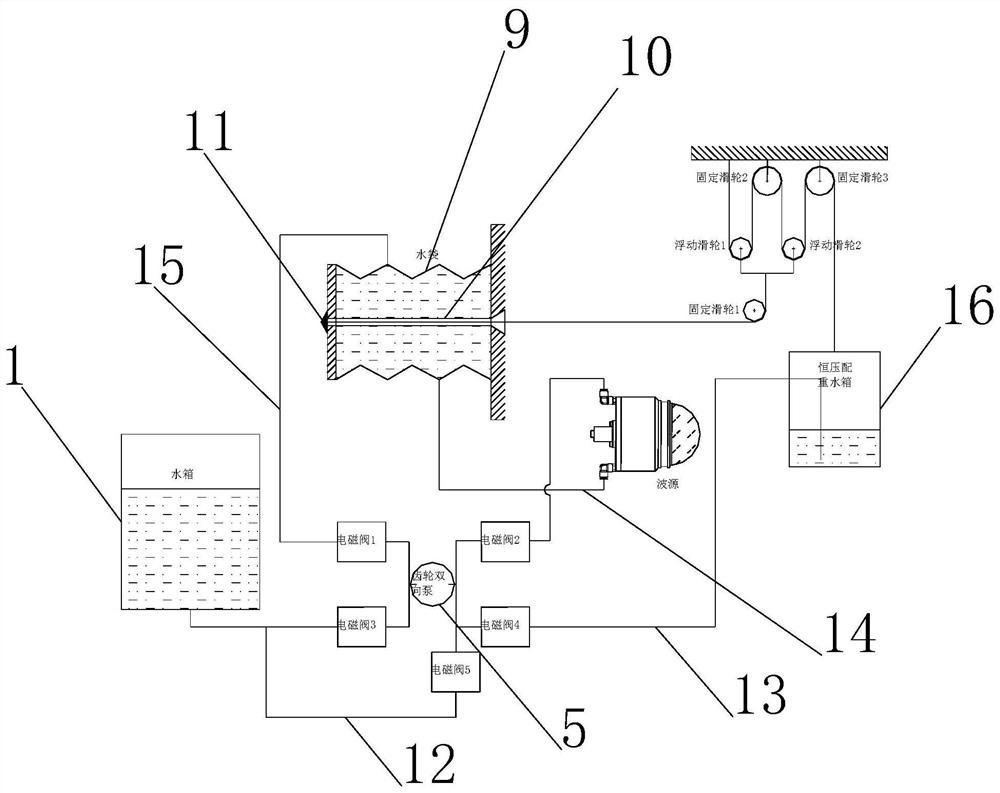

Embodiment 1

[0028] S1. First, inject an appropriate amount of water into the main water tank 1, the water bag 9 and the constant pressure counterweight water tank 16;

[0029] S2. Close solenoid valve three 3, solenoid valve five 4, solenoid valve four 5, solenoid valve two 7 and solenoid valve one 8, so that the constant pressure counterweight water tank 16 passes through the pulley device, and the pressure of 1:4 is transmitted to make the control The thread 23 is tightened, and the water bag 9 is squeezed, so that the water in the water bag 9 enters the wave source 2, so that the water bag expands;

[0030]S3. By opening solenoid valve 2 7 and solenoid valve 1 8, closing the other solenoid valves, turning on the gear bidirectional pump 6 and making the water flow direction from right to left, forming a water circulation system, in this cycle, the gas inside the wave source 2 will also be automatically discharged;

[0031] S4. By opening solenoid valve one 8 and solenoid valve five 4, ...

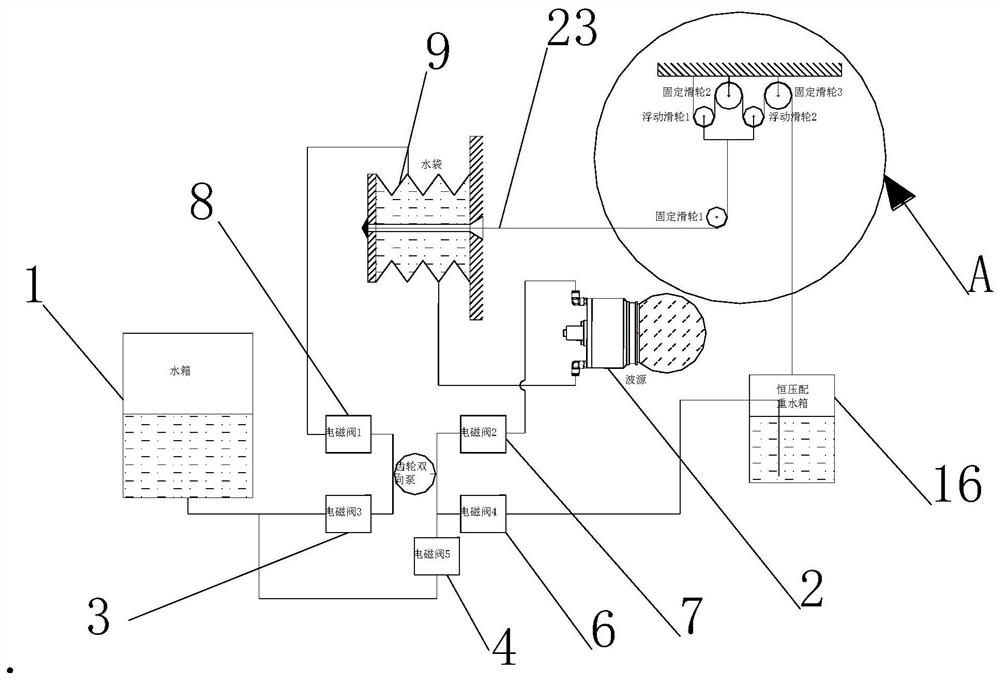

Embodiment 2

[0034] S1. First, inject an appropriate amount of water into the main water tank 1, the water bag 9 and the constant pressure counterweight water tank 16;

[0035] S2. Close solenoid valve three 3, solenoid valve five 4, solenoid valve four 5, solenoid valve two 7 and solenoid valve one 8, so that the constant pressure counterweight water tank 16 passes through the pulley device, and the pressure of 1:4 is transmitted to make the control The thread 23 is tightened, and the water bag 9 is squeezed, so that the water in the water bag 9 enters the wave source 2, so that the water bag expands;

[0036] S3. By opening solenoid valve 2 7 and solenoid valve 1 8, closing the other solenoid valves, turning on the gear bidirectional pump 6 and making the water flow direction from right to left, forming a water circulation system, in this cycle, the gas inside the wave source 2 will also be automatically discharged;

[0037] S4. By opening solenoid valve one 8 and solenoid valve five 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com