Gas-liquid two-phase flow field three-dimensional reconstruction system based on laser scanning

A technology of 3D reconstruction and laser scanning, which is applied in the direction of flow characteristics, image data processing, and measurement devices, can solve the problems of fluorescence intensity influence, dependence, and inability to obtain flow structure at the same time, and achieve high temporal and spatial resolution while low spatial resolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

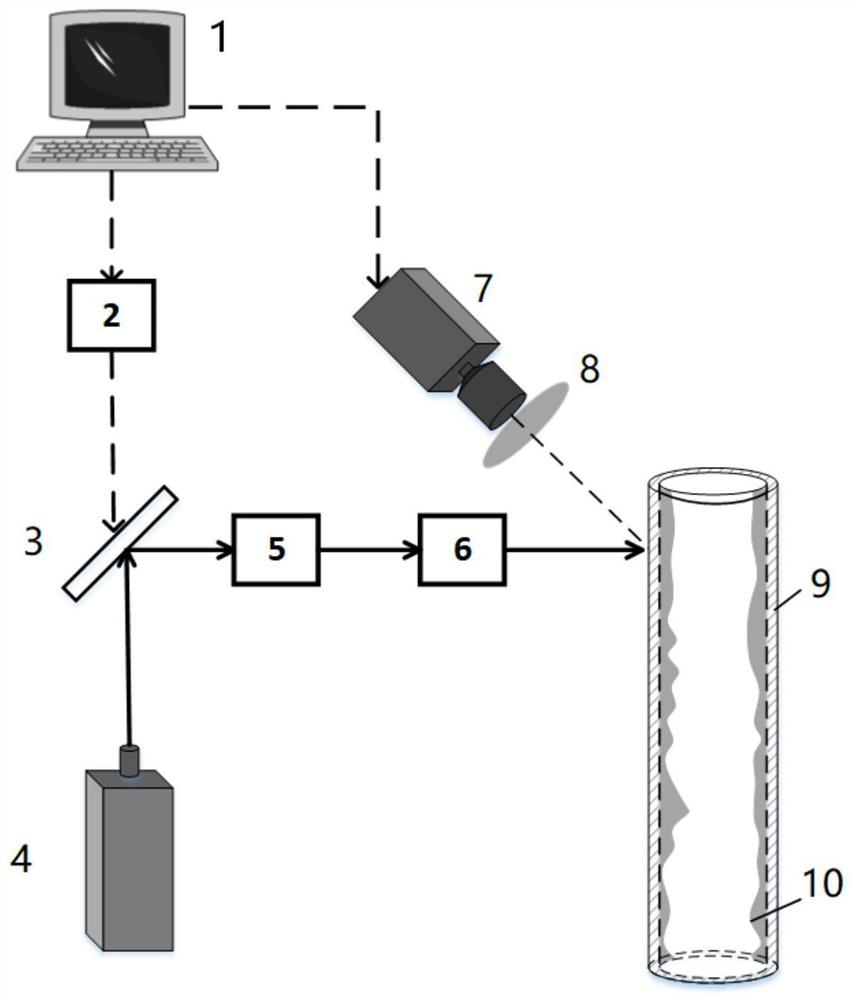

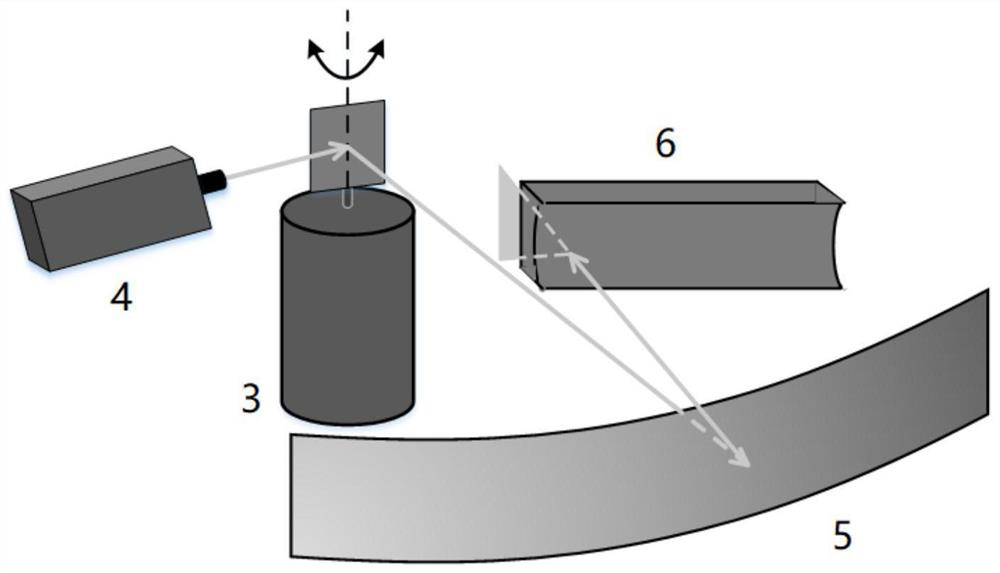

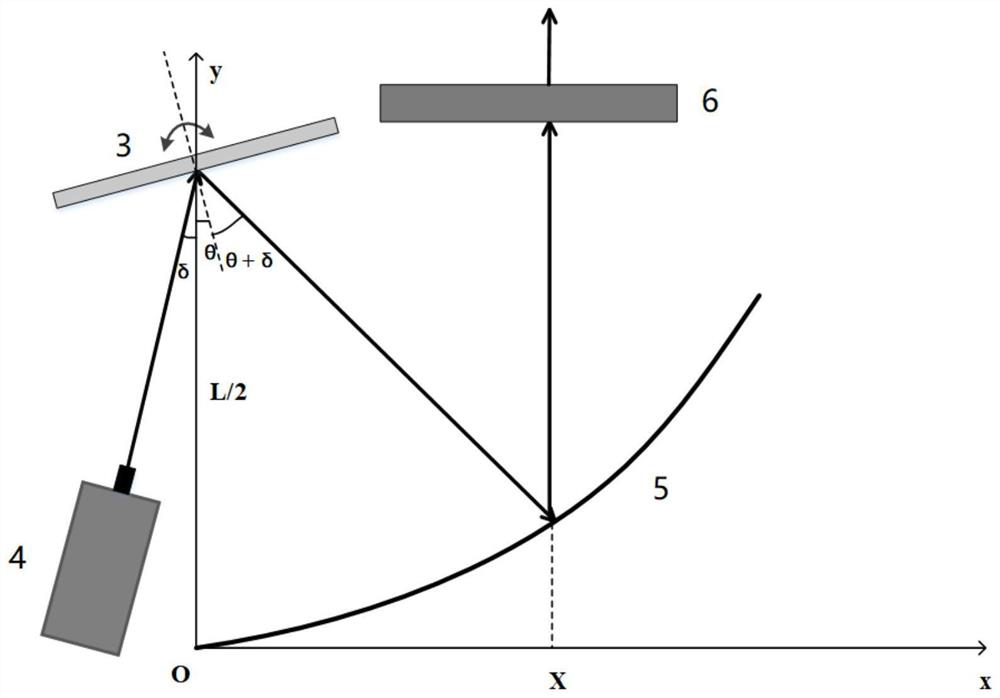

[0030] The three-dimensional reconstruction system of the gas-liquid two-phase flow field based on laser scanning of the present invention includes a computer (1), a vibrating mirror controller (2), a vibrating mirror (3), a laser (4), and a parabolic reflector L1 (5) , plano-concave cylindrical lens L2 (6), high-speed camera (7), optical filter F1 (8), measuring pipeline (9) and gas-liquid two-phase flow (10).

[0031] During specific implementation, the laser (4) selects a continuous laser with a wavelength of 532nm. The measuring pipe (9) is transparent and made of acrylic material, the liquid phase of the gas-liquid two-phase flow (10) in the measuring pipe (9) is added with fluorescent substance rhodamine B, and the lens of the high-speed camera (7) is equipped with a long-wavelength sensor with a wavelength of 570nm. pass filter (8).

[0032] During specific implementation, the computer (1) is connected to the vibrating mirror controller (2) and the high-speed camera (7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com