Preparation method for co-production of 2-methyl-1, 3-propylene glycol and pentaerythritol

A technology of pentaerythritol and propylene glycol, which is applied in the field of co-production of 2-methyl-1,3-propanediol and pentaerythritol, can solve the problems of large amount of waste water and low added value of by-products, achieve simple process flow and avoid large output , Improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

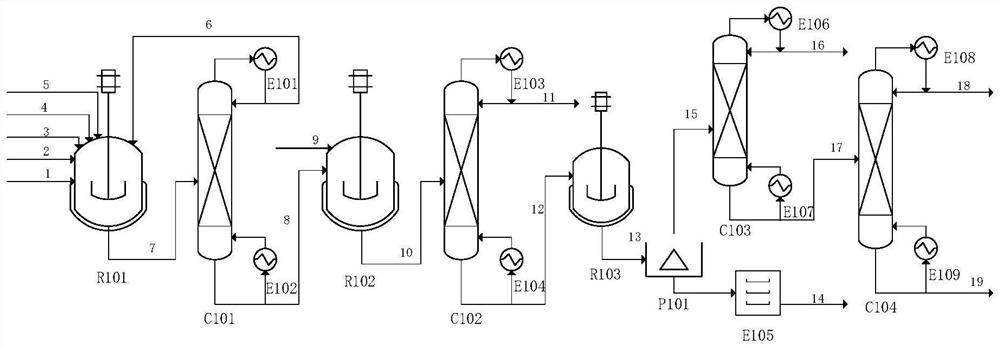

[0062] 37% aqueous formaldehyde solution (stream 1), acetaldehyde (stream 2), triethylamine (stream 3), and auxiliary agent (stream 4) are added to the condensation reaction in a molar ratio of 3:1:0.05:0.003 In the reactor R101, the molar amount of formaldehyde is based on the molar content of formaldehyde in the aqueous formaldehyde solution. At the same time, the top material (stream 6) of the condensation raw material recovery tower also enters the condensation reactor R101 for reaction. The reaction temperature is 80°C and the reaction pressure is 0.8 MPaA, residence time 0.5h. The condensation reaction solution (stream 7) generated after the reaction enters the condensation raw material recovery tower C101, the pressure of the condensation raw material recovery tower is 0.2MPaA, the theoretical plate number is 20 plates, the feeding position is 10 plates, and the reflux ratio is 2. The unreacted formaldehyde and part of the water (stream 6) obtained from the top of the t...

Embodiment 2

[0071] The molar ratio of 37% formaldehyde solution (stream 1), acetaldehyde (stream 2), trimethylamine (stream 3), additive (stream 4), and water (stream 5) is 10:1:0.02 :0.005:5 is added in the condensation reactor R101, wherein the molar weight of formaldehyde is based on the formaldehyde molar content in the formaldehyde aqueous solution, and the condensation raw material recovery tower top material (stream 6) also enters the reaction in the condensation reactor R101 simultaneously, The reaction temperature is 20°C, the reaction pressure is 0.2MPaA, and the residence time is 1h. The condensation reaction liquid (stream 7) generated after the reaction enters the condensation raw material recovery tower C101, the pressure of the condensation raw material recovery tower is 0.6MPaA, the number of theoretical plates is 30 plates, the feeding position is 20 plates, and the reflux ratio is 0.1. The unreacted formaldehyde and part of the water (stream 6) obtained from the top of t...

Embodiment 3

[0080] 37% formaldehyde solution (stream 1), acetaldehyde (stream 2), trimethylamine (stream 3), additives (stream 4), water (stream 5) in a molar ratio of 5:1:0.01 :0.01:10 is added in the condensation reactor R101, wherein the molar weight of formaldehyde is based on the formaldehyde molar content in the formaldehyde aqueous solution, and the condensation raw material recovery tower top material (stream 6) also enters the reaction in the condensation reactor R101 simultaneously, The reaction temperature is 50°C, the reaction pressure is 0.4MPaA, and the residence time is 2h. The condensation reaction liquid (stream 7) generated after the reaction enters the condensation raw material recovery tower C101, the pressure of the condensation raw material recovery tower is 0.5MPaA, the theoretical plate number is 10 plates, the feeding position is 5 plates, and the reflux ratio is 10. The unreacted formaldehyde and part of the water (stream 6) obtained from the top of the tower are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap