High-density high-detonation-velocity water-resistant seismic explosive column

A technology of seismic source charge and high detonation velocity, which is applied in the direction of blasting cylinders, weapon accessories, nitroalkane compositions, etc., and can solve the problems of difficult subsidence of blastholes, heavy environmental pollution, and poor water resistance, and achieve efficient utilization and avoid The effect of environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

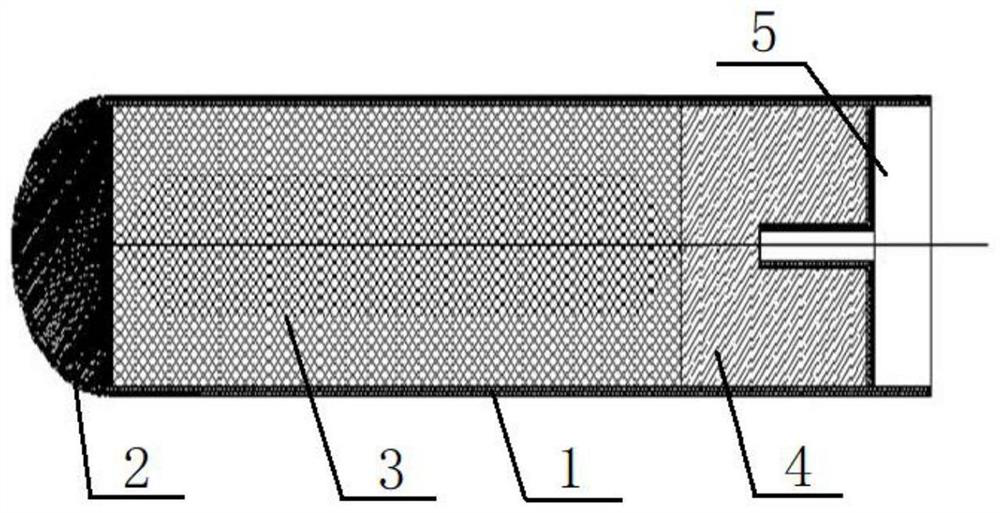

[0019] A high-density, high-detonation-velocity, water-resistant seismic source charge of the present invention comprises a source charge shell 1, a filling explosive 2, a main charge 3 and The priming charge 4 is arranged on the detonator seat 5 for detonating the priming charge at the rear end of the shell of the seismic source charge;

[0020] The mass percentages of each charge in the seismic source charge are: 60% of the main charge, 30% of the priming charge, and 10% of the filling charge;

[0021] The filling explosive is an emulsion explosive;

[0022] The main charge is a decommissioned double-base powder column;

[0023] The priming charge is a modified double-base powder column.

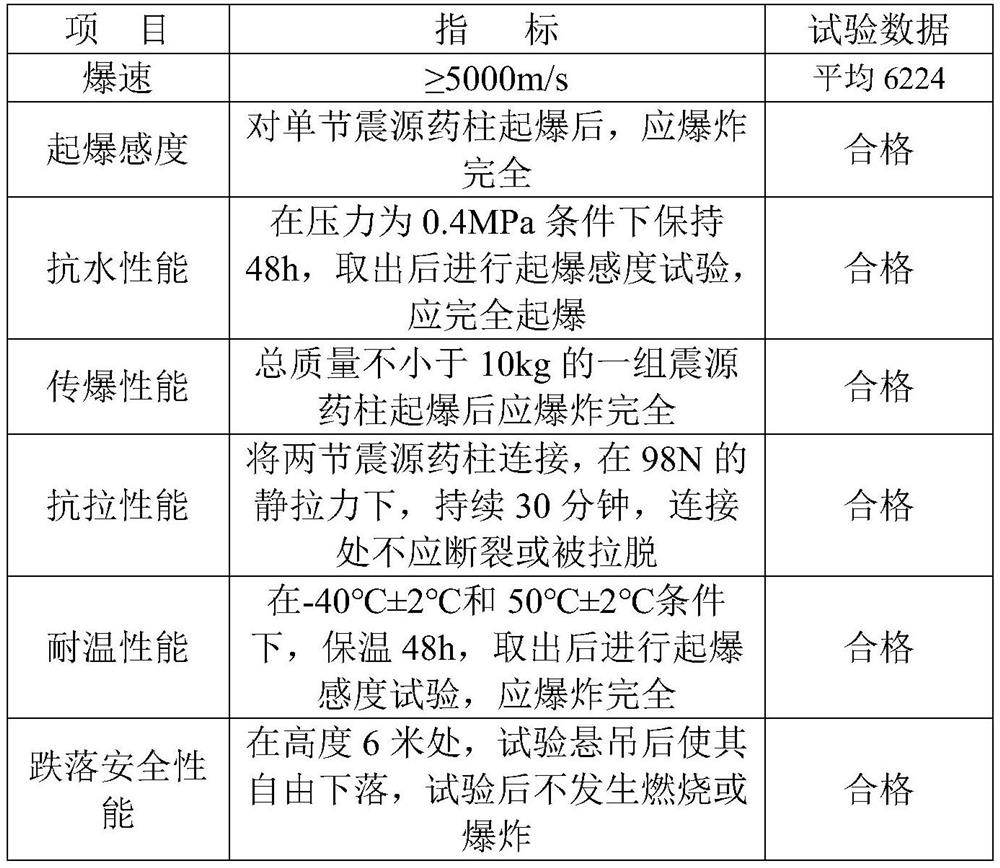

[0024] According to the test method specified in the GB15563 standard, performance tests are carried out on the detonation sensitivity, water resistance, detonation transfer performance, tensile performance, temperature resistance, drop safety, etc. of the high detonation velocity water-...

Embodiment 2

[0028] A high-density, high-detonation-velocity, water-resistant seismic source charge of the present invention includes a seismic source charge shell, and the filling explosive, main charge and priming charge that are sequentially filled in the inner cavity of the seismic source charge shell from front to back are arranged on The rear end of the shell of the seismic source charge is used to detonate the detonator seat of the priming charge;

[0029] The mass percentages of each charge in the seismic source charge column are: 70% of the main charge, 15% of the priming charge, and 15% of the filling explosive;

[0030] The filling explosive is an emulsion explosive;

[0031] The main charge is a decommissioned double-base powder column;

[0032] The priming charge is a modified double-base powder column.

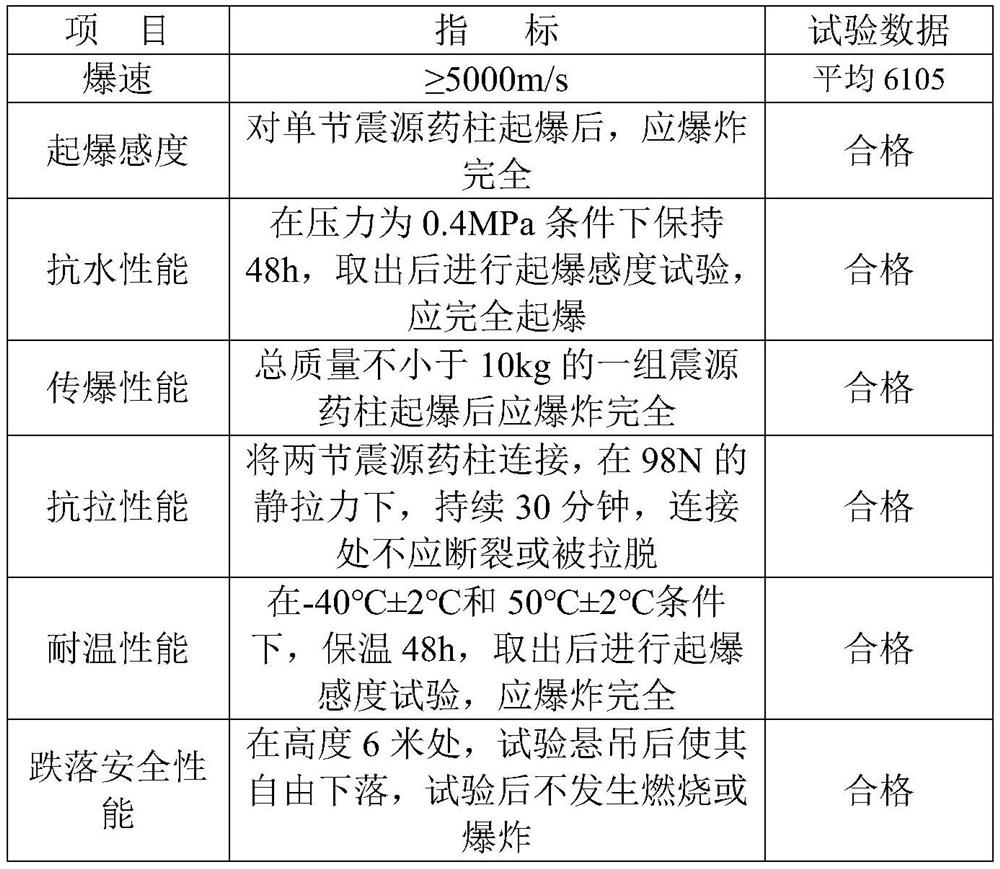

[0033] According to the test method specified in the GB15563 standard, performance tests are carried out on the detonation sensitivity, water resistance, detonation transfe...

Embodiment 3

[0037] A high-density, high-detonation-velocity, water-resistant seismic source charge of the present invention includes a seismic source charge shell, and the filling explosive, main charge and priming charge that are sequentially filled in the inner cavity of the seismic source charge shell from front to back are arranged on The rear end of the shell of the seismic source charge is used to detonate the detonator seat of the priming charge;

[0038] The mass percentages of each charge in the seismic source charge are: 75% of the main charge, 15% of the priming charge, and 10% of the filling explosive;

[0039] The filling explosive is an emulsion explosive;

[0040] The main charge is a decommissioned double-base powder column;

[0041] The priming charge is a modified double-base powder column.

[0042] According to the test method specified in the GB15563 standard, performance tests are carried out on the detonation sensitivity, water resistance, detonation transfer perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com