A wide volume fraction layered gradient boron carbide aluminum matrix composite material and its preparation method

A volume fraction, composite material technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of low volume fraction, poor bulletproof effect, and low interface bonding strength of the elastic panel, and achieve the cost The effect of low, high density, and high interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

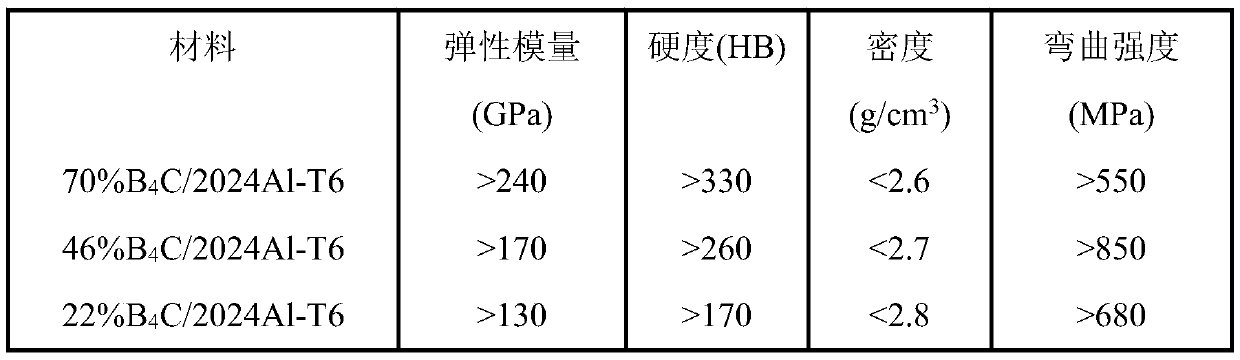

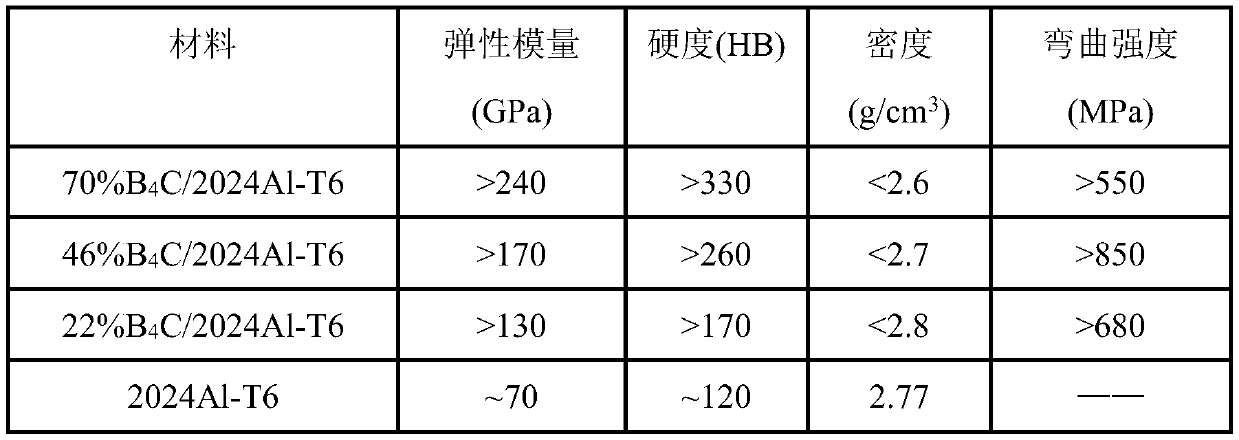

[0017] Specific embodiment 1: In this embodiment, a wide volume fraction layered gradient boron carbide aluminum matrix composite material is composed of a panel, a back panel and a transition intermediate layer; the transition intermediate layer is arranged between the panel and the back panel; the panel It is made of 70%-90% boron carbide and 10%-30% aluminum-containing material by volume fraction; the back plate is made of 0%-40% boron carbide and 60%-100% aluminum-containing material by volume fraction; The transition intermediate layer is a multi-layer boron carbide aluminum matrix composite material, and the volume fraction of boron carbide in each layer of boron carbide aluminum matrix composite material decreases equigradiently from the face plate to the back plate; the aluminum-containing material is aluminum or aluminum alloy.

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the panel is made of 70% to 90% boron carbide and 10% to 30% aluminum-containing materials by volume fraction; The volume fraction of boron carbide in the boron-aluminum matrix composite material is reduced layer by layer until the volume fraction of boron carbide in the back plate is 0-15%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the panel is made of 70% boron carbide and 30% aluminum-containing materials by volume fraction; each layer of boron carbide-aluminum matrix is composited from the panel to the back plate The volume fraction of boron carbide in the material is reduced layer by layer until the volume fraction of boron carbide in the back plate is 15-20%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com