Aircraft test fresh air control system and control method

A control system and control method technology, applied in the direction of aircraft component testing, etc., can solve the problems that cannot meet the needs of aircraft engine tests, etc., and achieve the effects of uniform and stable supply, stable temperature, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

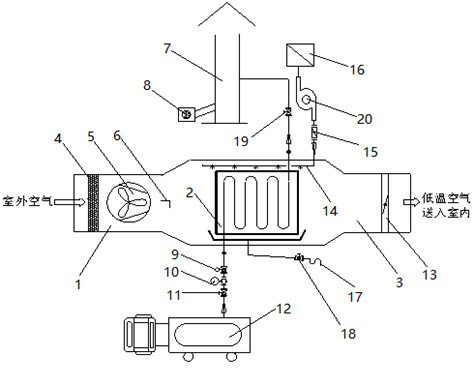

[0078] This embodiment is an aircraft test fresh air control system, comprising:

[0079] gas subsystem, such as figure 1 As shown, the supplementary air subsystem includes: a compensation air duct 1 for introducing outdoor air into the aircraft climate laboratory, a liquid nitrogen heat exchanger 2 connected with the compensation air duct 1 for cooling the outdoor air, and a liquid nitrogen heat exchanger 2 connected with the liquid nitrogen The heat exchanger 2 is connected to the air supply duct 3 for sending low-temperature air into the room. The air supply duct 3 is located outside the aircraft climate laboratory and communicates with the aircraft climate laboratory. The air supply duct 3 is provided with a damper 13, which also The control module located in the aircraft climate laboratory with local manual control and remote automatic control functions, the temperature monitoring module for monitoring the temperature of the supply air, the humidity monitoring module for ...

Embodiment 2

[0089] This embodiment is a method for controlling fresh air in aircraft tests based on Embodiment 1, such as Figure 8 shown, including the following steps:

[0090] S1. Before the test starts, the control system is powered on, and the liquid nitrogen inlet switch valve 11 and the nitrogen discharge switch valve 19 are opened;

[0091] S2, docking the liquid nitrogen tanker 12 with the liquid nitrogen heat exchanger 2, and adjusting the supply pressure of the liquid nitrogen tanker 12 to 4 Bar;

[0092] S3, start the nitrogen dilution fan 8;

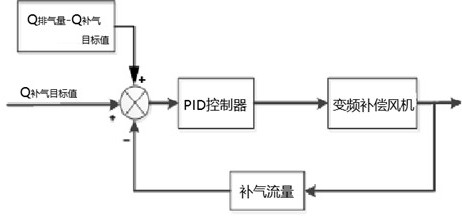

[0093] S4. The tester's mobile device is connected to the system through the wireless networking sub-module, and then the temperature setting sub-module is used to set the compensation air temperature target value , the PLC controller controls the frequency conversion compensation fan 5 to start at a low speed, and obtains the fresh air temperature at the outlet of the liquid nitrogen heat exchanger 2 through the temperature sensor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com