High-strength mineral wood fiber board and preparation method thereof

A wood fiber board, high-strength technology, applied in the field of fiberboard, can solve the problems of poor thermal insulation performance of SPC stone-plastic board, achieve good waterproof effect, improve wear resistance, scratch resistance, stain resistance, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention provides the preparation method of the high-strength wood fiber board described in the above scheme, comprising the following steps:

[0049] mixing the raw materials for the preparation of the fiberboard layer to obtain a mixture;

[0050] Pave the mixture into a slab, and after compaction, obtain a single-layer board;

[0051] The single-layer boards are stacked into a mold, molded, and the mold is removed, and the obtained boards are sequentially dried, sanded and cured to form a fiber board layer to obtain a high-strength wood fiber board.

[0052] The invention mixes the preparation raw materials of the fiber board layer to obtain the mixture. The present invention has no special requirements on the mixing process, as long as the preparation raw materials can be mixed evenly. In the embodiment of the present invention, specifically, mixing equipment is used to stir for 40 to 60 minutes.

[0053] After the mixed material is obtained, the pre...

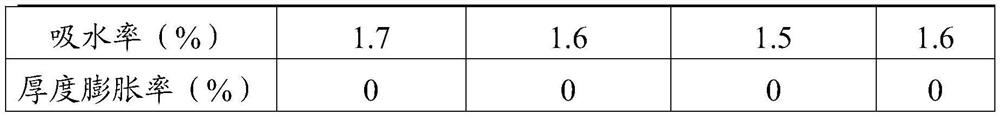

Embodiment 1

[0069] 1. Mixing of raw materials: 15 parts of light-burned magnesium oxide, 12 parts of magnesium sulfate, 5 parts of talcum powder, 1.5 parts of magnesium phosphate, 2 parts of sulfuric acid (mass fraction is 52%); add 6 parts of water to the above ingredients, stir until uniform; then Add 12 parts of 3-10mm pine fiber, 28 parts of 1-3mm poplar fiber, 25 parts of 100-200 mesh wood flour, and stir for 45 minutes with the mixing equipment to obtain the mixture;

[0070] 2. Slab laying: the mixed material is sent through the automatic laying equipment, and the formed slab is evenly laid on the entire width through the automatic feeding hopper, and the laying thickness is 40mm;

[0071] 3. Preliminary compaction: put it into a 3200T press for compaction and consolidation, the pressure is 15MPa, and keep for 20s to obtain a single-layer board;

[0072] 4. Crystallization and solidification: stack the single-layer boards on the pressure mold, one mold stacks 25 sheets, press the p...

Embodiment 2

[0081] 1. Mixing of raw materials: 18 parts of light-burned magnesium oxide, 15 parts of magnesium sulfate, 6 parts of talcum powder, 2 parts of calcium phosphate, 3 parts of sulfuric acid (55% by mass); add 5 parts of water to the above ingredients, and stir until uniform; then Add 15 parts of 3-10mm straw fiber, 25 parts of 1-3mm straw fiber, 25 parts of 100-200 mesh wood powder, and stir for 40 minutes with the mixing equipment to obtain the mixture;

[0082] 2. Slab laying: the mixed material is sent through the automatic laying equipment, and the formed slab is evenly laid on the entire width through the automatic feeding hopper, and the laying thickness is 60mm;

[0083] 3. Preliminary compaction: put it into a 3200T press for compaction and consolidation, the pressure is 12MPa, and keep for 25s to obtain a single-layer board;

[0084] 4. Crystallization and solidification: stack the single-layer boards to the pressure mold, stack 20 sheets in one mold, pressurize the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com