Automatic mold cleaning device for PC component production line

An automatic cleaning and production line technology, applied in the direction of manufacturing tools, grinding workpiece brackets, grinding machines, etc., can solve the problems that affect the quality of PC component production, the construction effect of benefits, the mold is easily damaged and deformed, and the cleaning is not in place, etc., to improve Water recycling efficiency, cost reduction, effect of reducing dust and garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

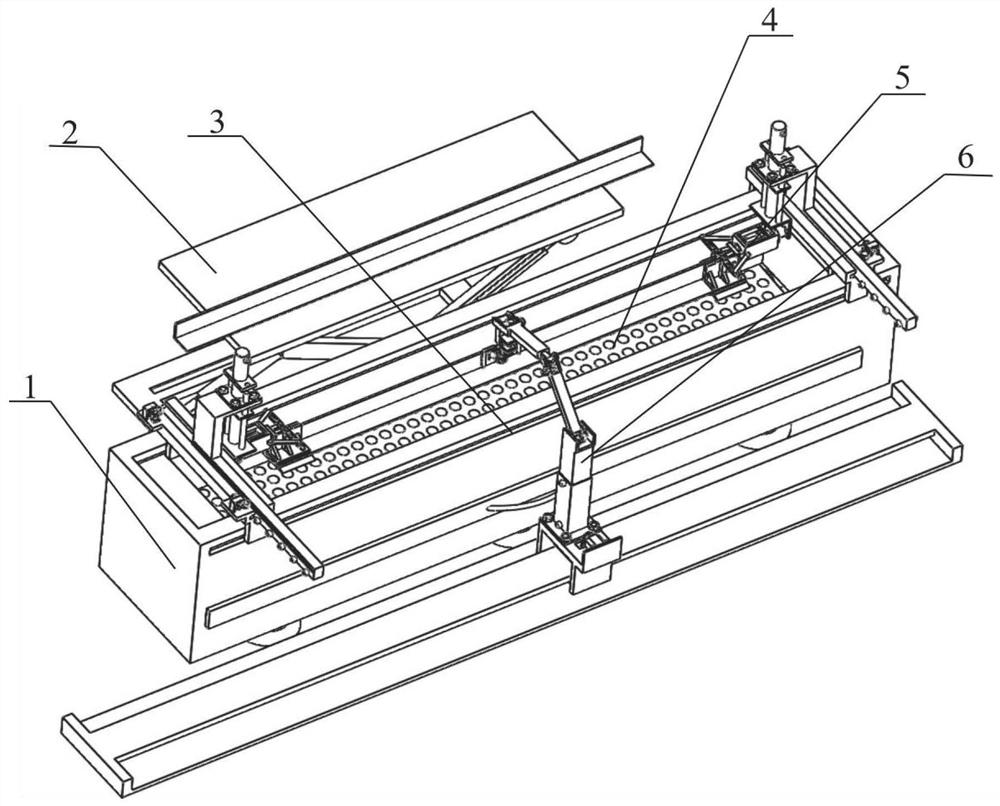

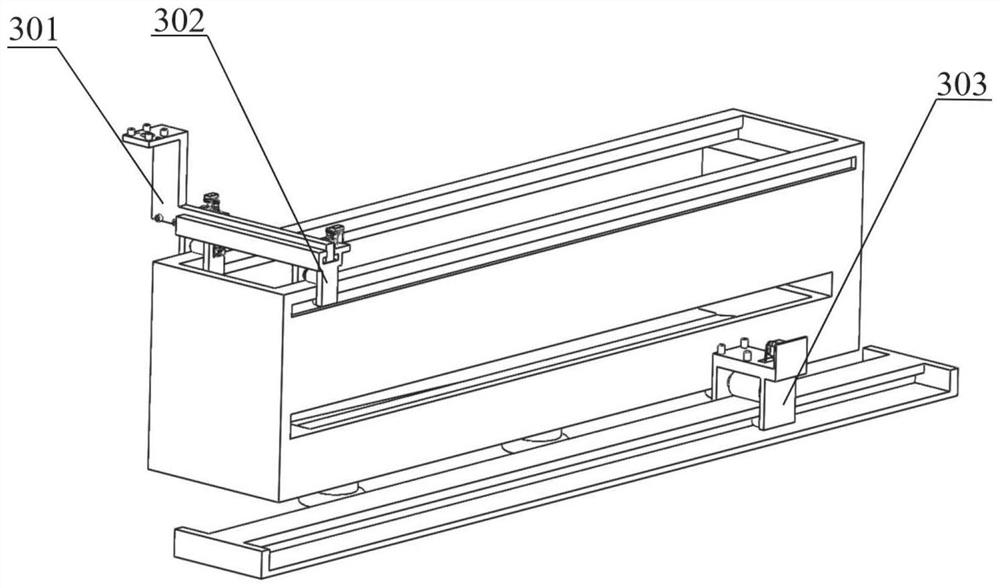

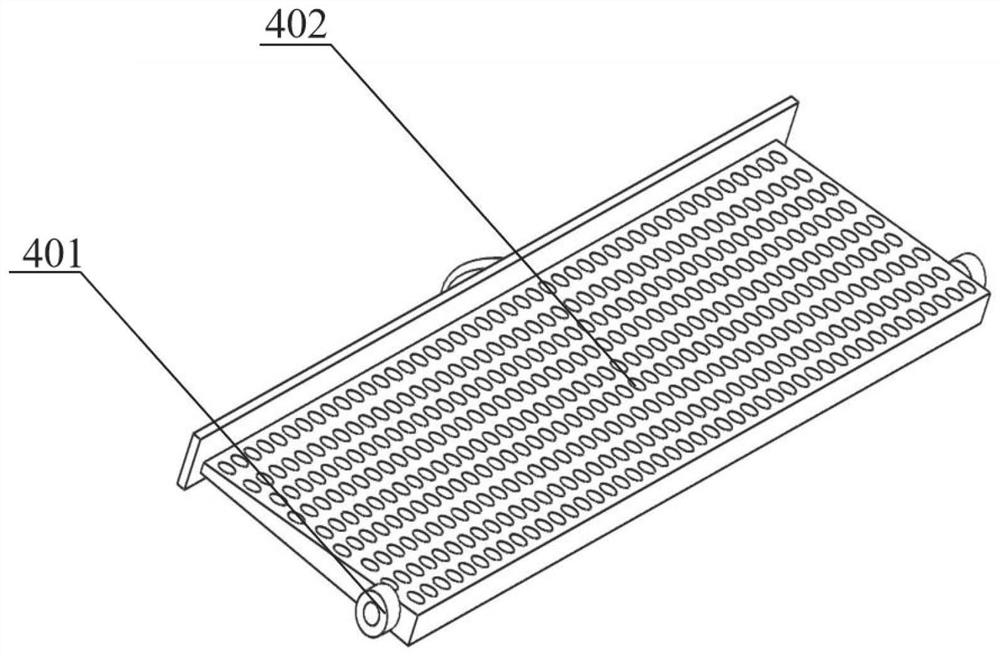

[0015] An automatic mold cleaning device for a PC component production line, which is composed of a cleaning pool 1, a lifting platform 2, a moving device 3, a slag-water separation device 4, a clamping device 5, and a cleaning manipulator 6. The moving device 3 It is composed of a traverse trolley 301, a longitudinal trolley 302 and a longitudinal trolley 303. The slag-water separation device 4 is composed of a rotating wheel 401 and a high-frequency vibrating screen 402. The clamping device 5 is It is composed of fixture 501, connecting rod device 502, hydraulic device one 503, large bevel gear 504, small bevel gear 505, hydraulic device two 506, and the cleaning manipulator 6 is composed of a mobile base 601, a hydraulic support seat 602, a primary Composed of a mechanical arm 603, a secondary mechanical arm 604, a tertiary mechanical arm 605, a high-pressure nozzle 606, and an electric wire roller brush 607. In the guide rail groove on the upper part of the cleaning tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com