Full-biodegradable mulching film for peanut planting

A technology for degradable mulch and peanut planting, applied in plant protection, plant protection covers, botanical equipment and methods, etc., can solve the problems of accelerated degraded mulch aging and water evaporation, poor barrier and weather resistance, and decreased moisture retention. Achieve the effect of improving water retention, realizing aging resistance and improving water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0036] The preparation method that embodiment 1-6 adopts is:

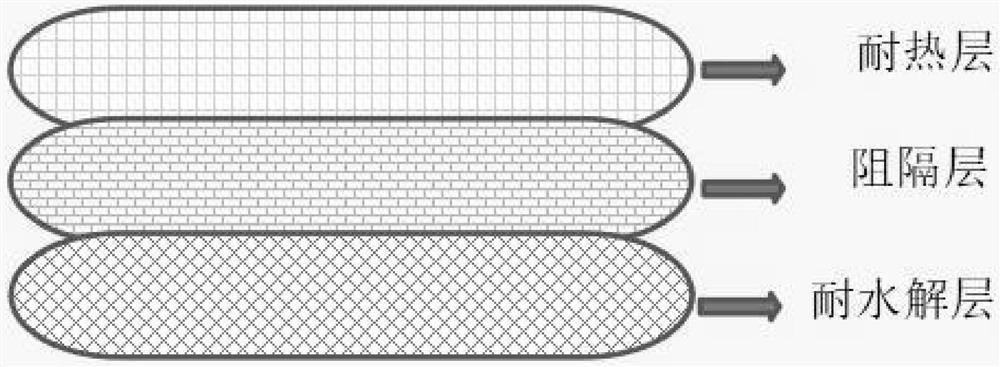

[0037] Step 1: According to the materials required for the heat-resistant layer, barrier layer and hydrolysis-resistant layer, use the corresponding high-mixer to mix them evenly, and then send them to the corresponding twin-screw extruder for granulation, and the twin-screw extruder extrudes The outlet temperature is 150-190°C. After the granulation is completed, heat-resistant layer particles, barrier layer particles and hydrolysis-resistant layer particles are obtained;

[0038] Step 2: Send the heat layer particles, barrier layer particles and hydrolysis-resistant layer particles into the three-layer co-extrusion film blowing machine, and control the film blowing temperature at 160-185°C, inflation ratio 3-4, and film thickness 0.006-0.012mm blown film under the conditions to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com