Olefin block copolymer-based hot melt adhesive composition

A technology of hot melt adhesive and olefin block, which is applied in the directions of polymer adhesive additives, adhesives, adhesive additives, etc. Effects of spray uniformity, excellent bond strength, excellent wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7 and comparative example 1 to 7

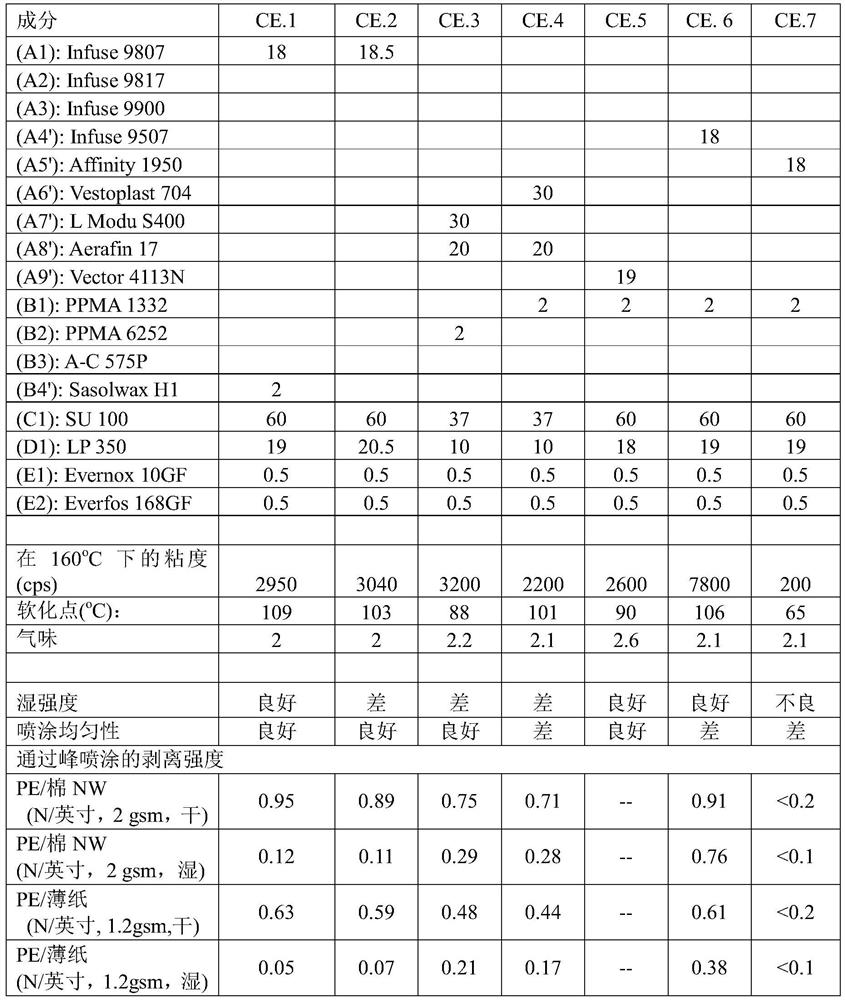

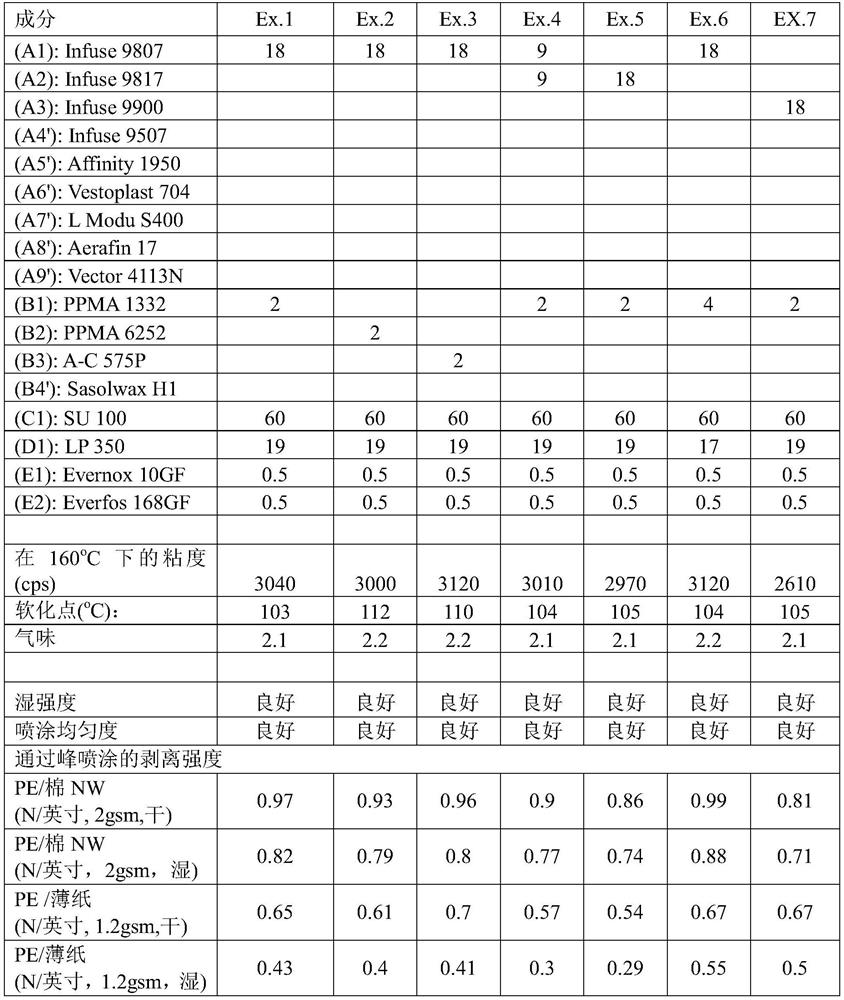

[0137] Adhesives were prepared by conventional methods in the art using the components in the amounts (parts by weight) listed in Table 1, and their properties were tested by the above-mentioned methods, and the evaluation results are shown in Table 1.

[0138] Table 1:

[0139]

[0140] Table 1 (continued):

[0141]

[0142] As can be seen from Table 1, the adhesives of the present invention (Ex. 1 to 7) exhibited good wet strength, good odor, good wet bond strength and good spray uniformity.

[0143] Comparative Examples 1 to 2 (CE.1 and CE.2) did not use MA grafted wax, Comparative Examples 3 to 5 and 7 (CE.3 to CE.5 and CE.7) did not use OBC, and Comparative Example 6 ( CE.6) Use MA grafted wax and OBC with MI outside the range of 10 to 35g / 10min (@190°C, 2.16kg); compared to the adhesive of the present invention, they all exhibit one or more unsatisfactory performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com