Medium-temperature oxidation-resistant nickel-based corrosion-resistant alloy and preparation process thereof

A technology for corrosion-resistant alloy and preparation process, applied in the field of corrosion-resistant alloy, can solve the problems of poor cold and hot processing performance, high manufacturing cost, difficult welding, etc., and achieve the effects of excellent corrosion resistance, low production cost, and moderate room temperature strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

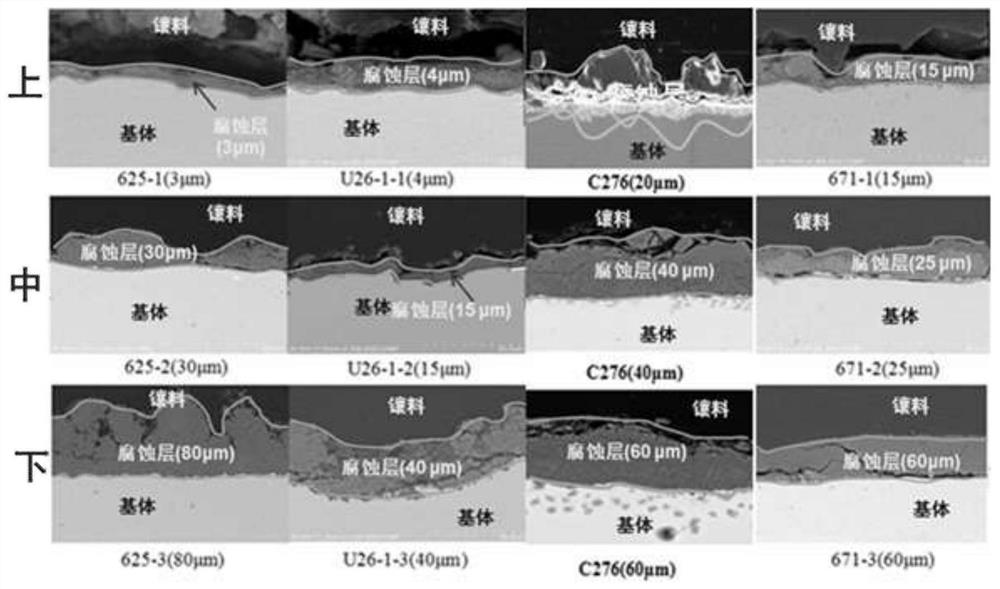

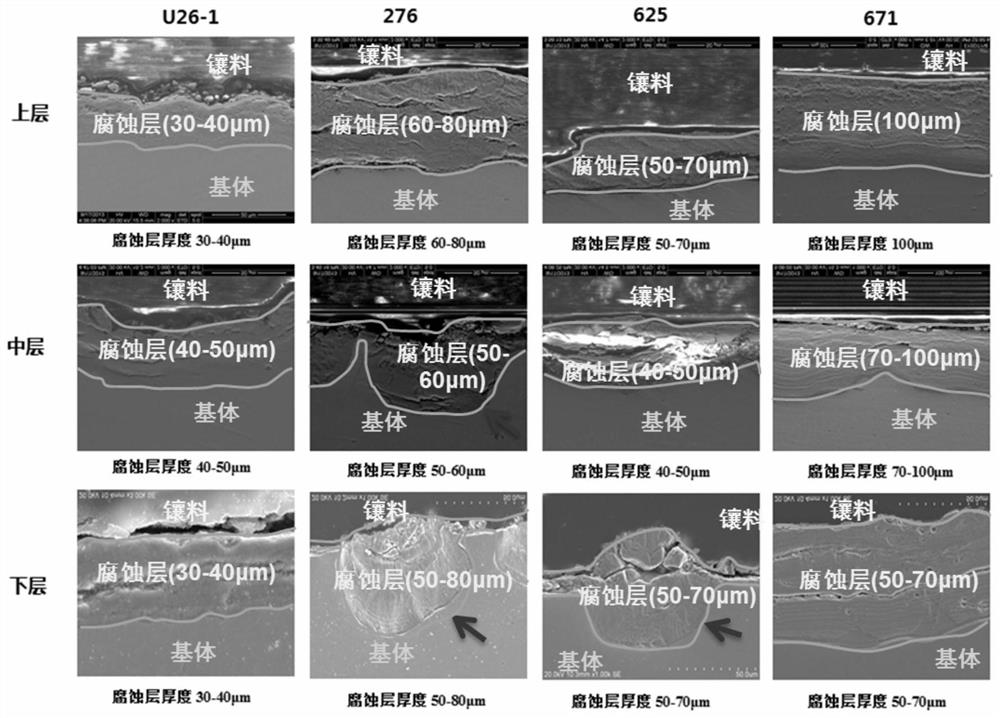

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Three 20kg ingots were melted in a vacuum induction furnace, and the ingots were directly forged and hot-rolled into bars with a diameter of 14mm. The initial deformation temperature of forging and hot rolling is 1150-1170°C, and the final deformation temperature is not lower than 950°C. The chemical composition of hot-rolled bars is shown in Table 1.

[0029] The heat treatment system of the alloy of the present invention is solid solution at 1100-1150° C., the holding time varies depending on the size of the finished alloy, and the minimum holding time is 30 minutes.

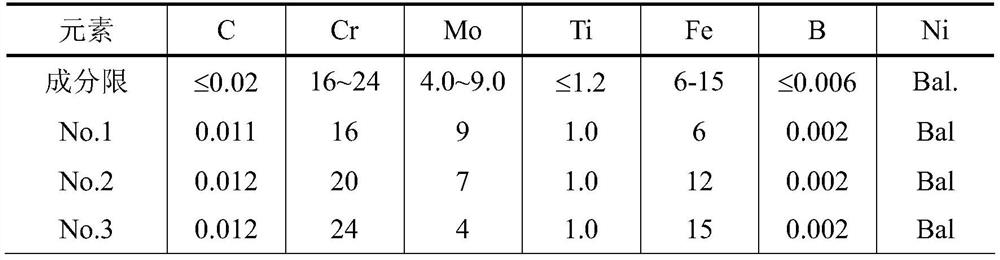

[0030] Table 1 adopts three kinds of alloy chemical composition (wt.%) of the present invention of vacuum induction furnace smelting

[0031]

[0032] No.1, No.2 and No.3 alloys in Table 1 were solid solution treated at 1150°C for 30min, and the instantaneous mechanical properties...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com