A kind of rhodium-platinum alloy nano flower and preparation method thereof

A platinum alloy and nanoflower technology, applied in the field of nanomaterials, can solve problems such as complex preparation methods, low reaction repetition rate, and poor dispersion, and achieve easy large-scale production, good size uniformity, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Firstly, 9.9mg rhodium trifluoroacetate and 11.8mg platinum acetylacetonate were stirred and dissolved in 3mL oleylamine at room temperature; then 300mg CTAB and 5mL oleylamine were mixed in a 20mL seed bottle; then the seed bottle was heated at 200°C After stirring for 10 minutes in a heating platform, 3 mL of oleylamine containing the precursor was injected, and the reaction was carried out at 200 °C for 2 h. After the reaction is over, the reaction solution is centrifuged to obtain rhodium-platinum alloy nanoflowers.

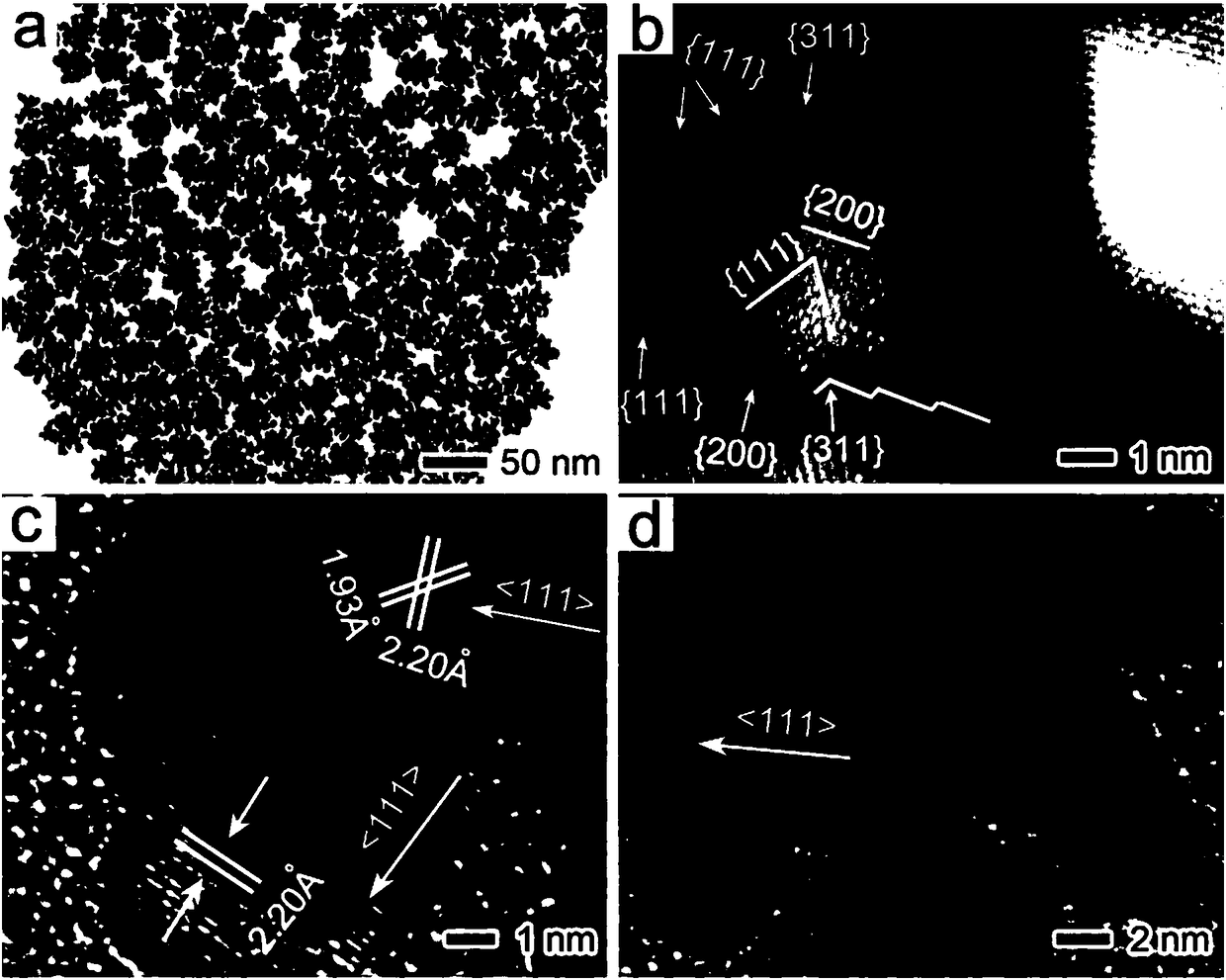

[0040] The TEM morphology of rhodium-platinum alloy nanoflowers is as follows: figure 1 As shown in (a), the size distribution of nanoflowers is uniform, with a diameter of 20-45nm, a stamen width of 2-9nm, and a length of 5-20nm; figure 1 (b) prepares the scanning transmission electron microscope (STEM) figure of the rhodium-platinum nanoflower for the present embodiment, and figure (c, d) prepares the high-resolution transmission electron microscope...

Embodiment 2

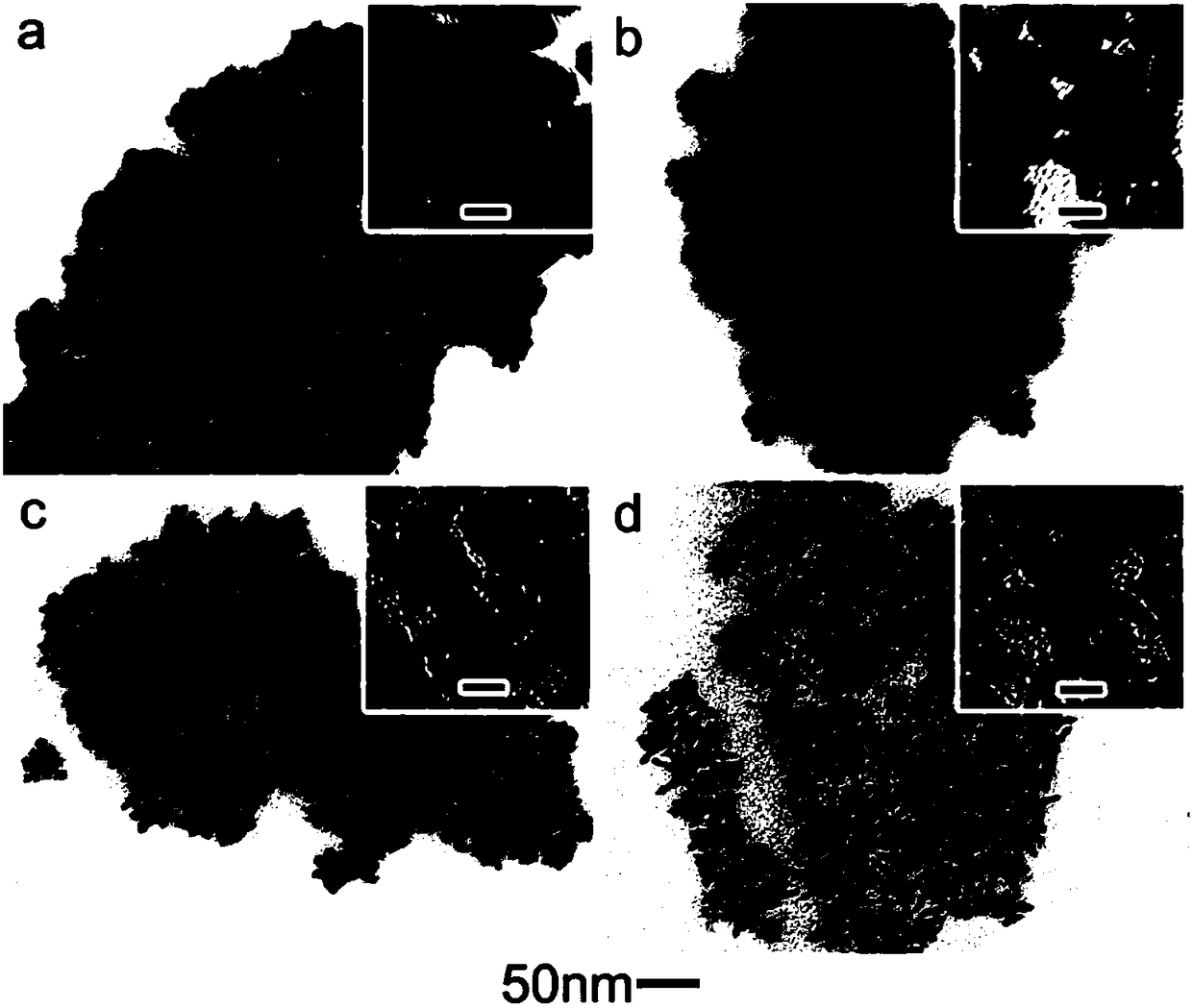

[0042] Firstly, 3.3mg rhodium trifluoroacetate and 19.7mg platinum acetylacetonate were stirred and dissolved in 3mL oleylamine at room temperature; then 300mg CTAB and 5mL oleylamine were mixed in a 20mL seed bottle; then the seed bottle was heated at 200°C After stirring for 10 minutes in a heating platform, 3 mL of oleylamine containing the precursor was injected, and the reaction was carried out at 200 °C for 2 h. After the reaction is over, the reaction solution is centrifuged to obtain rhodium-platinum alloy nanoflowers, such as image 3 (a).

Embodiment 3

[0044] Firstly, 6.6mg rhodium trifluoroacetate and 15.7mg platinum acetylacetonate were stirred and dissolved in 3mL oleylamine at room temperature; then 300mg CTAB and 5mL oleylamine were mixed in a 20mL seed bottle; then the seed bottle was heated at 200°C After stirring for 10 minutes in a heating platform, 3 mL of oleylamine containing the precursor was injected, and the reaction was carried out at 200 °C for 2 h. After the reaction is over, the reaction solution is centrifuged to obtain rhodium-platinum alloy nanoflowers, such as image 3 (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com