Anti-counterfeiting one-dimensional photonic crystal film and preparation method thereof

A dimensional photonic crystal and optical disc technology, which is applied in the field of anti-counterfeiting, can solve the problems of complex preparation method and high cost of photonic crystal materials for anti-counterfeiting, and achieve the effects of environmental friendliness, good anti-counterfeiting effect and good concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the one-dimensional photonic crystal film for anti-counterfeiting provided by the present invention comprises: adding polyvinyl alcohol into water, heating and stirring to dissolve to obtain a polyvinyl alcohol solution, cooling the polyvinyl alcohol solution and injecting it into a one-dimensional photonic crystal mold, drying Release the mold to prepare a one-dimensional photonic crystal film for anti-counterfeiting.

[0031] Among them: the mass volume ratio (g / mL) of polyvinyl alcohol and water is 0.5-1:10. For example, you can choose 0.5:10, 0.8:10, 1:10, etc.

[0032] The temperature of heating and stirring is 80-100°C. For example, 80°C, 82°C, 85°C, 90°C, 95°C, 97°C, 100°C, etc. can be selected.

[0033] The drying temperature is 20-40°C. For example, 20°C, 25°C, 28°C, 30°C, 31°C, 35°C, 40°C, etc. can be selected.

[0034] The drying time is 15-48h. For example, 15h, 20h, 25h, 33h, 35h, 40h, 45h, 48h, etc. can be selected.

[0035]...

Embodiment 1

[0042] A method for preparing a one-dimensional photonic crystal film for anti-counterfeiting, comprising:

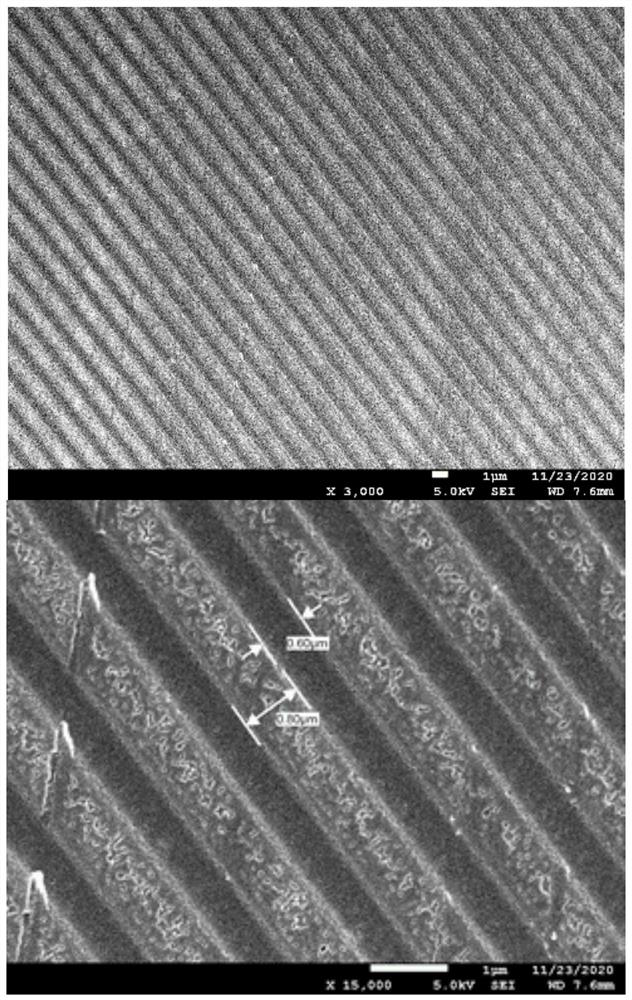

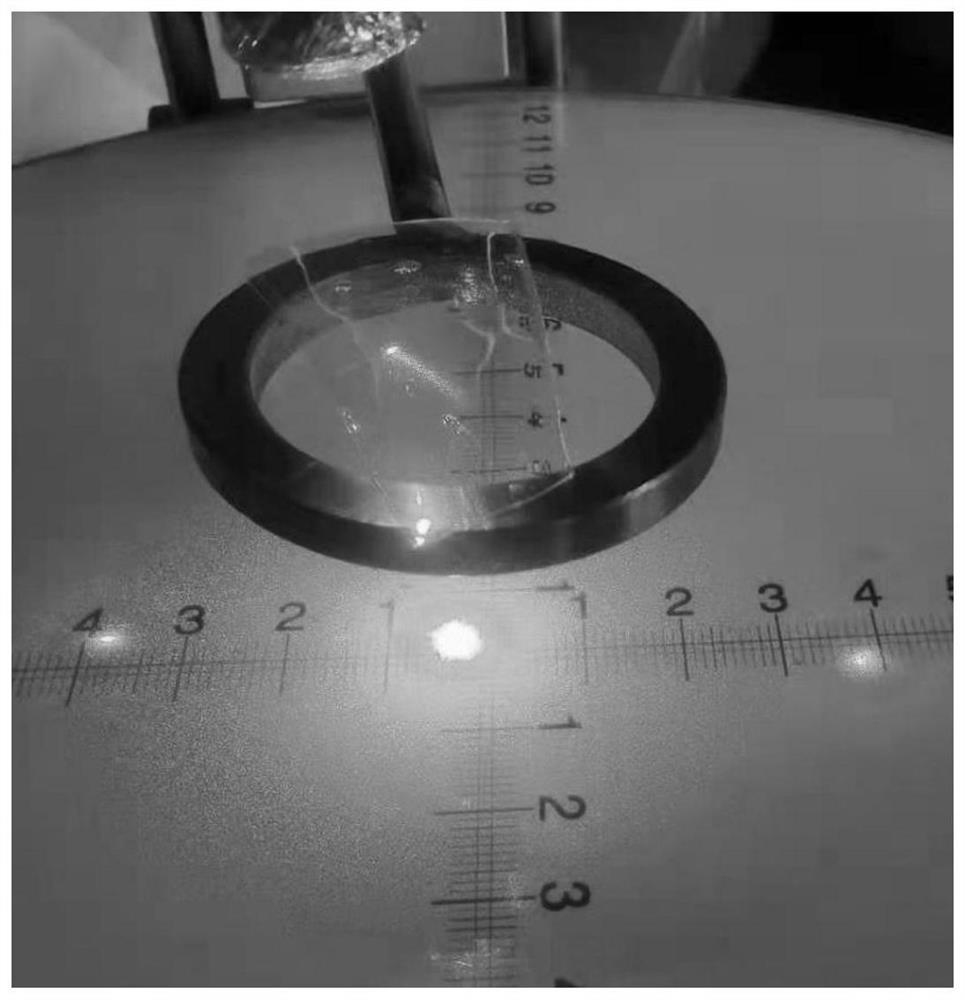

[0043]Weigh 2.0g of polyvinyl alcohol (PVA), add 30ml of deionized water, stir magnetically at 85°C for 60min until completely dissolved, cool to room temperature, let stand for 24h to remove air bubbles, and obtain the PVA solution; cut the DVD disc into 2cm* 4.5cm rectangle, then clean the grooved side of the disc with ethanol, remove the polymer on it, blow dry, and place the grooved side of the disc against the glass sheet to prepare a one-dimensional photonic crystal mold with a sandwich structure; The PVA solution was injected into a one-dimensional photonic crystal mold, and dried at 25° C. for 24 hours to prepare a one-dimensional photonic crystal film for anti-counterfeiting.

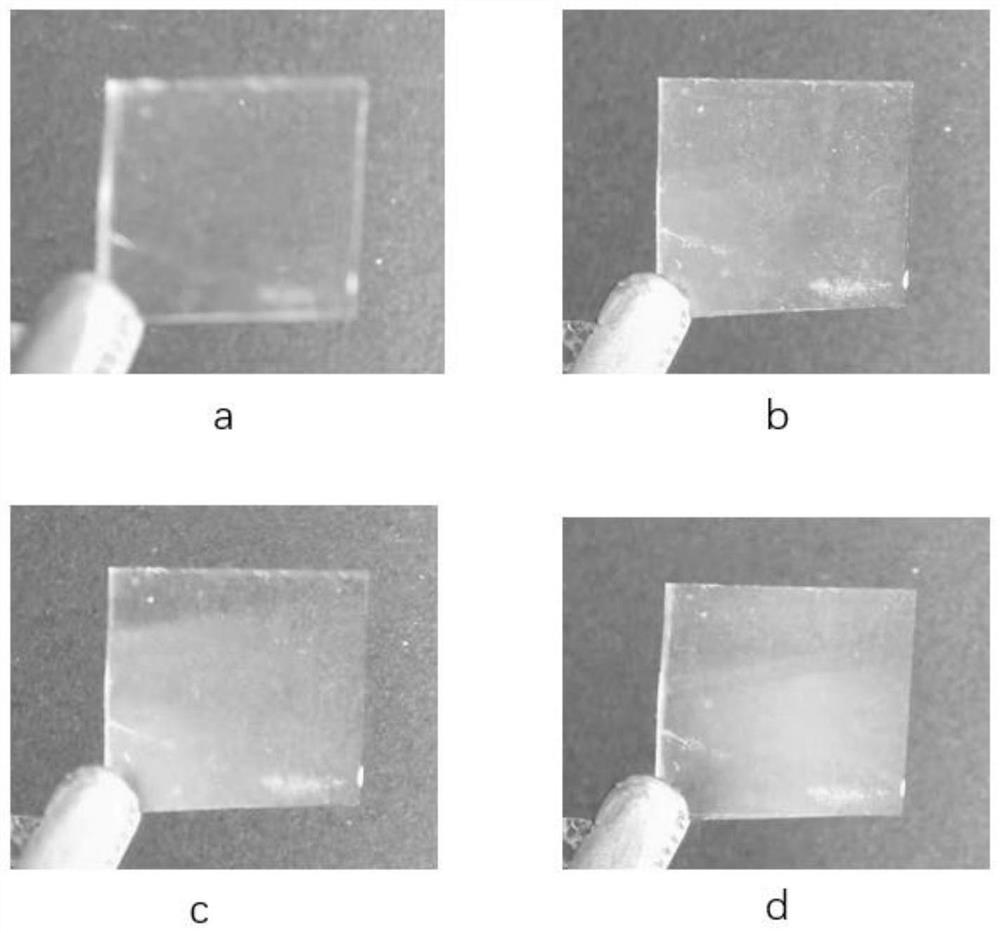

[0044] The anti-counterfeiting one-dimensional photonic crystal film prepared in this embodiment has high transparency, colorless, soft texture, good toughness, can be bent freely and do...

Embodiment 2

[0046] A method for preparing a one-dimensional photonic crystal film for anti-counterfeiting, comprising:

[0047] Weigh 1.5g of polyvinyl alcohol (PVA), add 30ml of deionized water, stir magnetically at 80°C for 60min until completely dissolved, cool to room temperature, let stand for 18h to remove air bubbles, and obtain a PVA solution; inject the PVA solution into a one-dimensional photon The crystal mold (the one-dimensional photonic crystal mold is the same as that in Example 1) was placed at 40° C. and dried for 36 hours to prepare a one-dimensional photonic crystal film for anti-counterfeiting.

[0048] The anti-counterfeiting one-dimensional photonic crystal film prepared in this example has high transparency, colorless, soft texture, good toughness, can be bent arbitrarily and is not easy to leave traces; when rotated at a certain angle under natural light, it will appear as a whole with obvious iridescent colors, and the light source is added. The structural color i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com