Drum-type vertical spindle cotton picking system

A drum-type, cotton-picking technology, applied in the direction of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of high use and maintenance costs, high price, inconvenient disassembly and assembly, and achieve easy line spacing adjustment, low cost, maintenance and cleaning convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

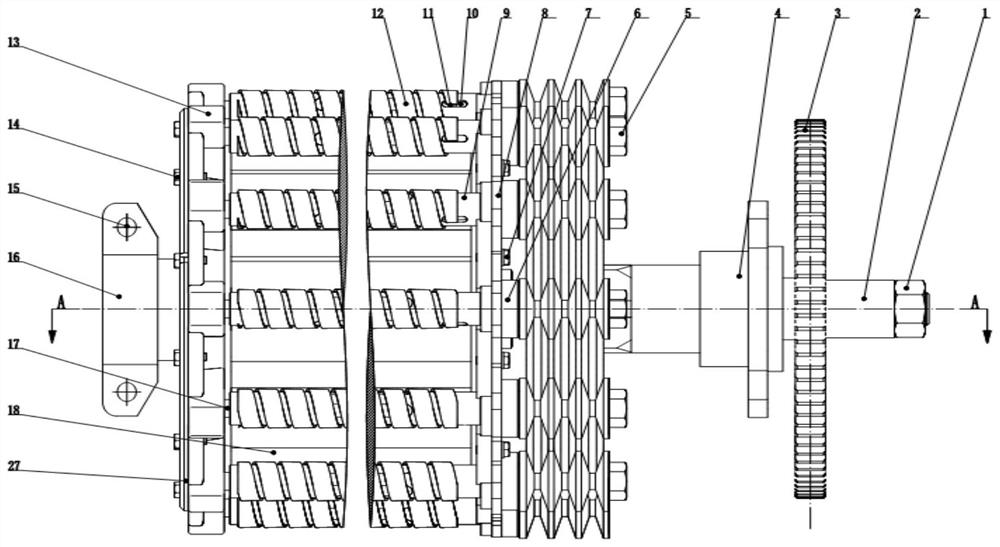

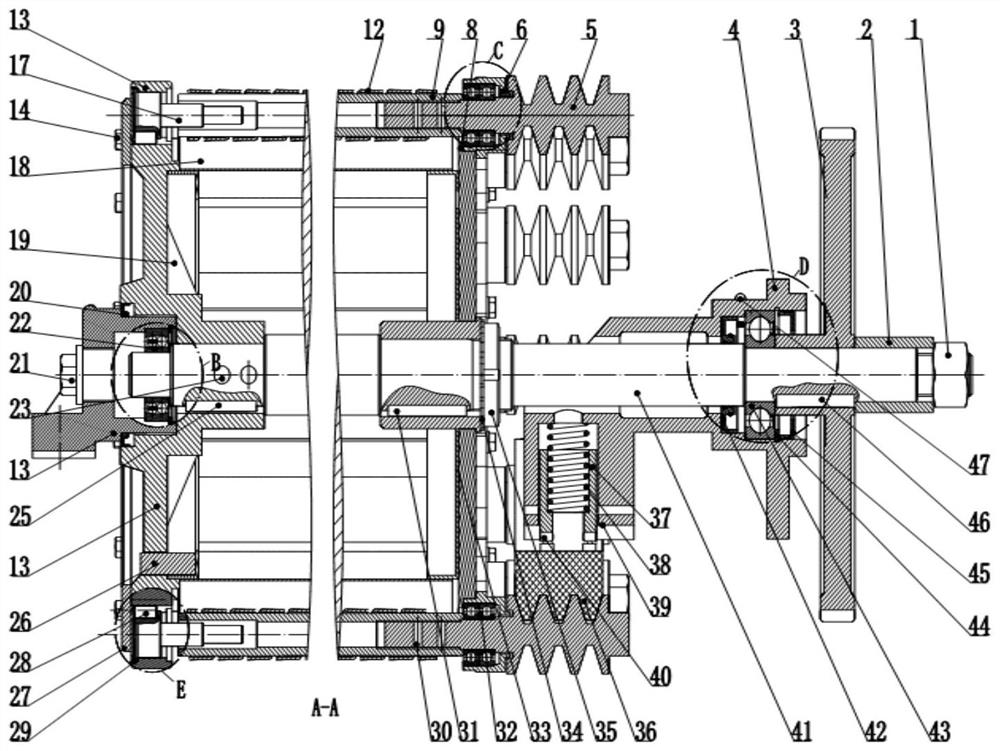

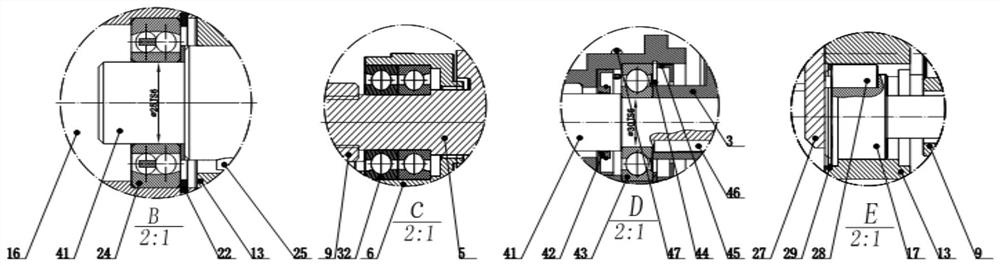

[0013] exist Figure 1 to Figure 4 In the implementation shown, one end of the main shaft (41) is assembled with the inner ring hole of the self-aligning bearing (43) installed on the bearing seat (16) under the main shaft, and the main hole of the lower plate of the cotton picking tube (13) is connected to one end of the main shaft (41). Assemble, and fix with the main shaft pin hole (23) through the flat key (25), the middle end of the main shaft (41) is connected with the flat key (31) of the cotton picking cylinder upper plate (8), and through the round nut (35) and the anti-loosening The gasket (34) fixes the upper plate (8) to each other, and the other end of the main shaft (41) is assembled in series with the sealing rings (42 and 45), the inner ring of the self-aligning bearing (43) and the gear (3), and the self-aligning bearing ( 43) Outer surface and sealing rings (42 and 45) and the outer ring are matched with the curved bearing seat (4), and the gear (3) is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com