Performance testing method and pipe string for expanding packer

A test method and packer technology, which is applied in fluid tightness test, machine/structural component test, mechanical component test, etc. It can solve problems such as rubber tube breakage, damage, expansion packer failure, etc. To achieve the effect of accurate and effective performance testing, accurate and true test results, and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] The performance testing method of the expandable packer of the present invention may include a simulation test stage performed on the ground, and a well-entry test stage performed downhole. The performance of the expansion packer can be effectively tested through two test stages.

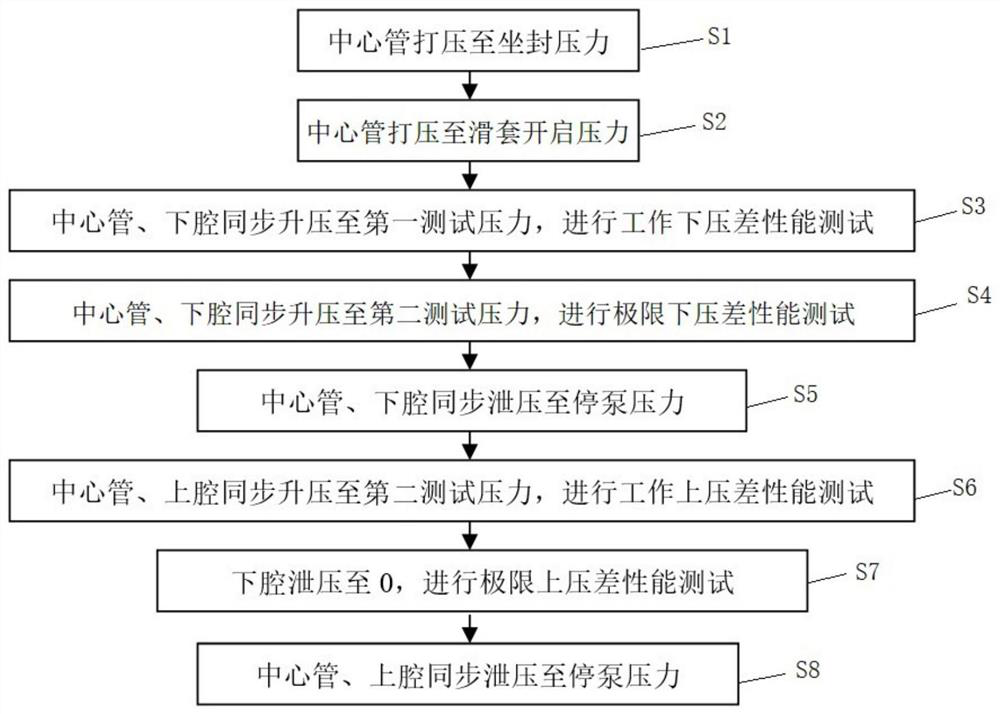

[0026] figure 1 The procedure for the simulation testing phase described above is shown.

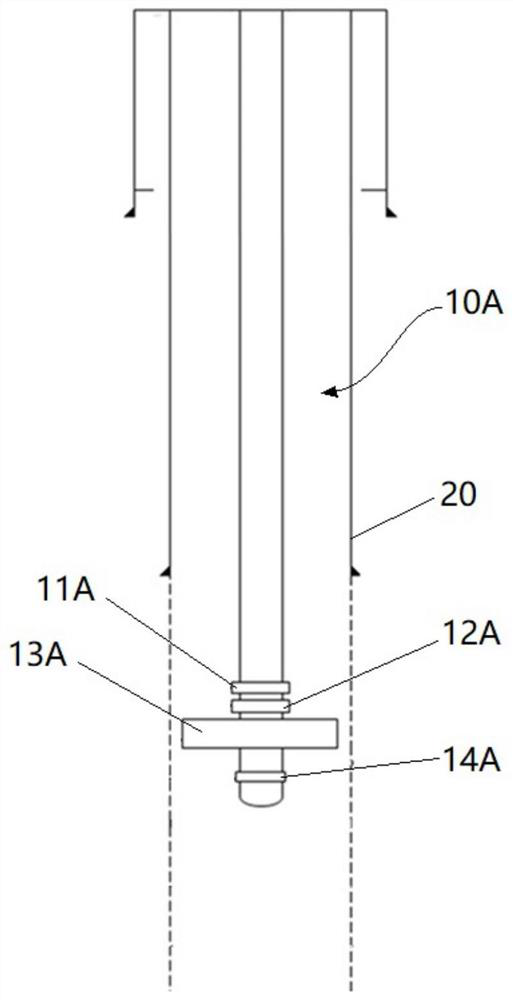

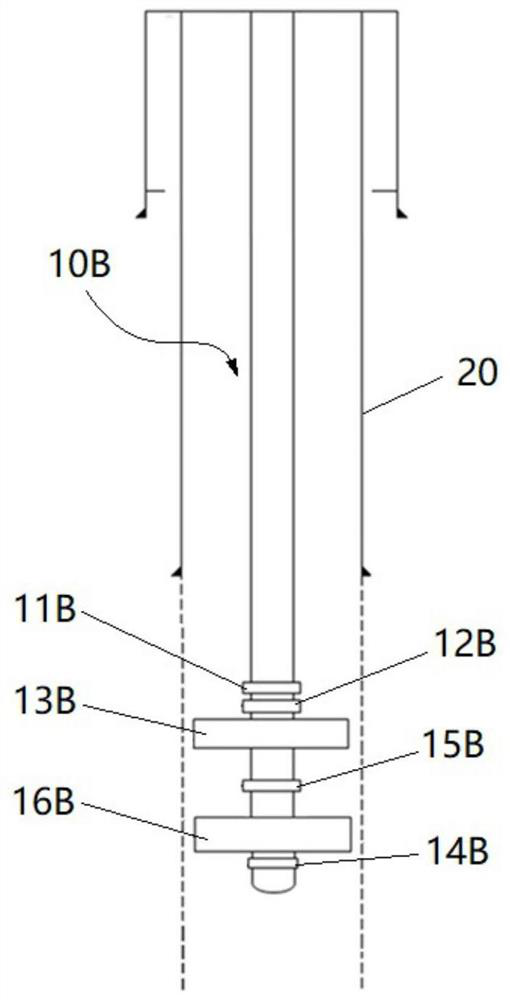

[0027] In this simulated testing phase, the packers to be tested are first assembled into the base pipe and then put together into a casing that simulates the well wall.

[0028] In step S1, the center pipe is pressurized to raise the pressure to the setting pressure of the packer to be tested. Thus, the rubber sleeve of the packer to be tested can be expanded and set on the inner wall of the sleeve. The set packer to be tested divides the space inside the casing into an upper chamber and a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com