Oil-based needle coke raw material deep decompression pretreatment system

An oil-based needle coke and pretreatment technology, which is applied in the treatment of hydrocarbon oil, coking carbonaceous materials, coke ovens, etc., can solve the problems of high steam production cost and high energy consumption, and reduce energy consumption and steam production cost. , the effect of simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, the specific embodiments of the invention will be further described in detail below in conjunction with the accompanying drawings.

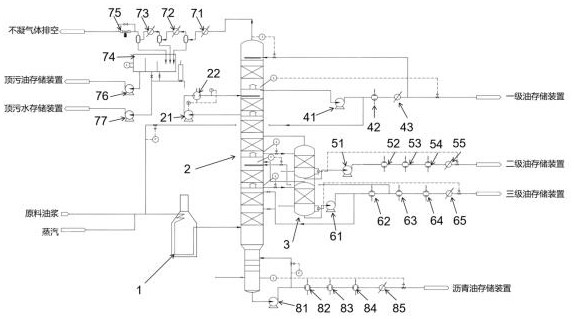

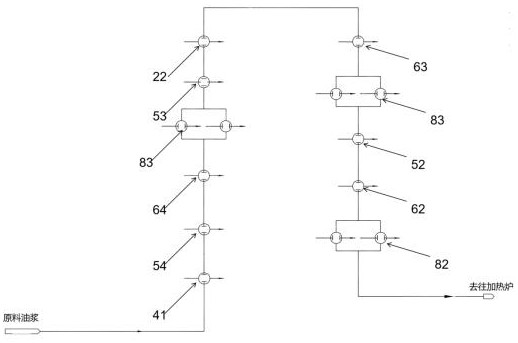

[0042] as attached figure 1 , figure 2 As shown, the oil-based needle coke raw material deep vacuum pretreatment system provided by the present invention includes a heating furnace 1, a vacuum tower 2, a vacuum stripping tower 3, a first-line oil outlet system, a second-line oil outlet system, and a third-line oil outlet system. system, top sewage oil outlet system, asphalt oil outlet system, oil slurry heat exchange system, heating furnace 1 is connected with decompression tower 2, and decompression tower 2 includes medium oil pump 21 and medium oil heat exchanger 22, which are sequentially connected with The top sewage oil outlet system, the first-line oil outlet system, the vacuum stripper, and the asphalt oil outlet system are connected; the upper half of the vacuum stripper 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com