Heat insulation film, preparation method thereof and air pillow type film structure

A heat-insulating film and film structure technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as rising indoor temperature, increasing energy consumption for cooling, and difficulty in meeting the energy-saving requirements of three-star green buildings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

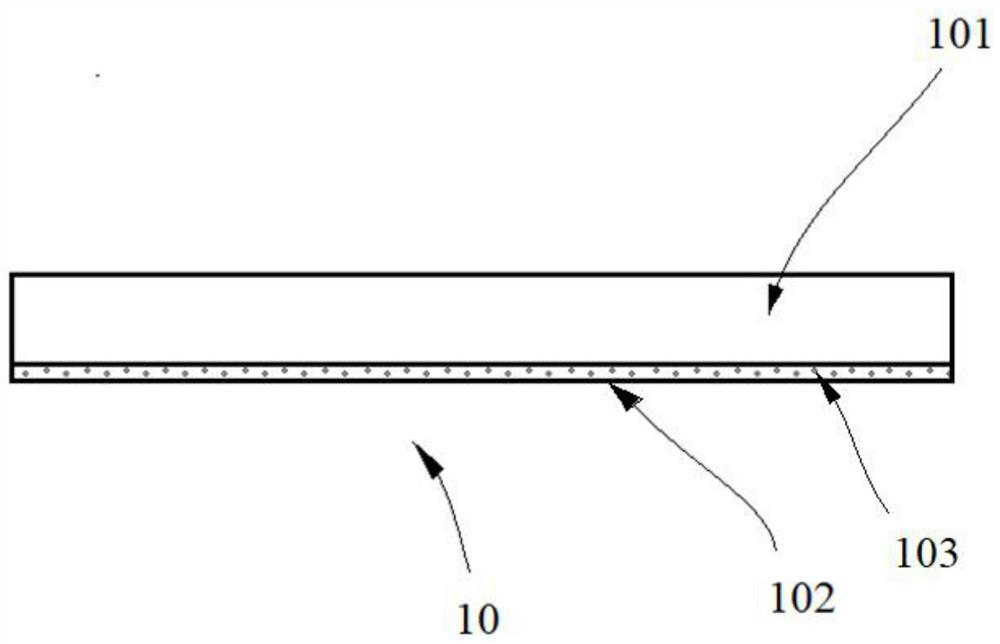

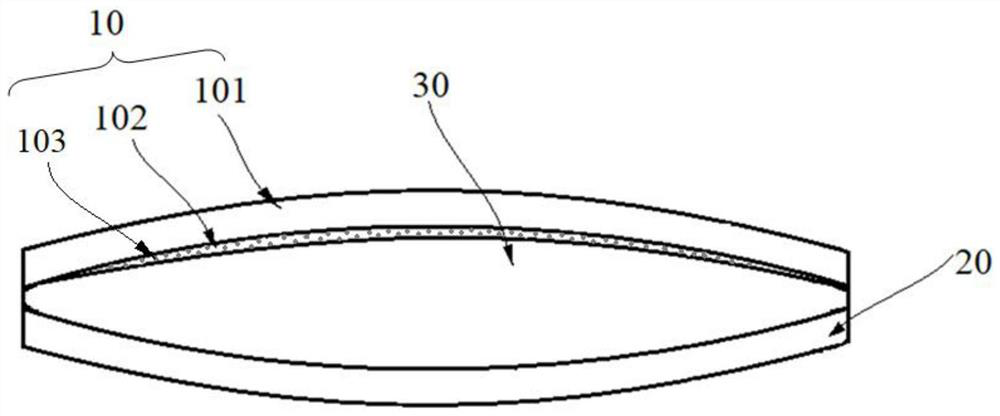

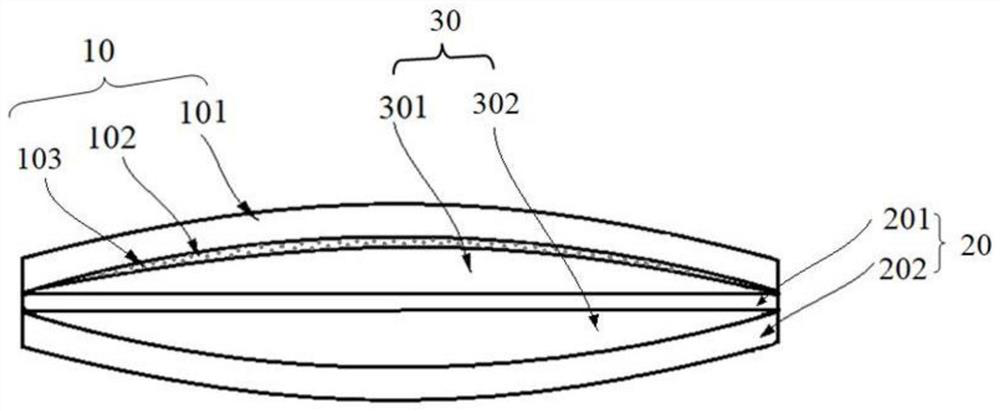

[0056] The present invention provides a method for preparing the heat insulation film 10 as described above, comprising the following steps:

[0057] S1, providing a photoselective lyosol with Tyndall effect, wherein the photoselective lyosol contains the first resin and cesium tungsten bronze 103; and

[0058] S2, providing an ethylene-tetrafluoroethylene copolymer film 101, and placing the photoselective liquid sol on any surface of the ethylene-tetrafluoroethylene copolymer film 101, so that the photoselective liquid sol forms a photoselective coating 102, The heat insulating film 10 was obtained.

[0059] The photoselective sol provided in step S1 has the Tyndall effect, so as to ensure that the cesium tungsten bronze 103 is uniformly dispersed in the photoselective sol.

[0060] Specifically, in the photoselective sol, based on 100 parts by weight of the first resin, the mass of cesium tungsten bronze 103 is 5 parts by weight to 35 parts by weight, more preferably 10 par...

Embodiment 1

[0090] Mix 10 parts by weight of cesium tungsten bronze 103 (with an average particle size of 40nm) and 40 parts by weight of ethyl acetate as a dispersion medium, and grind with nano-grinding equipment to uniformly disperse the tungsten-cesium bronze to obtain a slurry of tungsten-cesium bronze.

[0091] Mix 100 parts by weight of polyurethane resin, 80 parts by weight of ethyl acetate, 10 parts by weight of isocyanate, and 4 parts by weight of UV328, and then add 50 parts by weight of tungsten-cesium bronze slurry to obtain a mixture. Use a 300-mesh filter cloth The mixture was filtered to obtain a photoselective lyosol. After testing, the photoselective sol has the Tyndall effect, and the tungsten-cesium bronze is uniformly dispersed in the photoselective sol.

[0092] Provide an ethylene-tetrafluoroethylene copolymer film 101 with a thickness of 200 μm, and corona treat any surface of the ethylene-tetrafluoroethylene copolymer film 101 so that the surface tension is 60 dyn...

Embodiment 2

[0094] Example 2 Referring to the implementation of Example 1, the difference is that the polyurethane resin is replaced by an acrylic resin. After testing, the photoselective lyosol has Tyndall effect, and the tungsten-cesium bronze is uniformly dispersed in the photoselective lyosol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com