Treatment method of phenol-containing wastewater in coal chemical industry

A treatment method and technology for phenolic wastewater, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as shortage, and achieve improved biodegradability, reduced biological toxicity, and stable and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

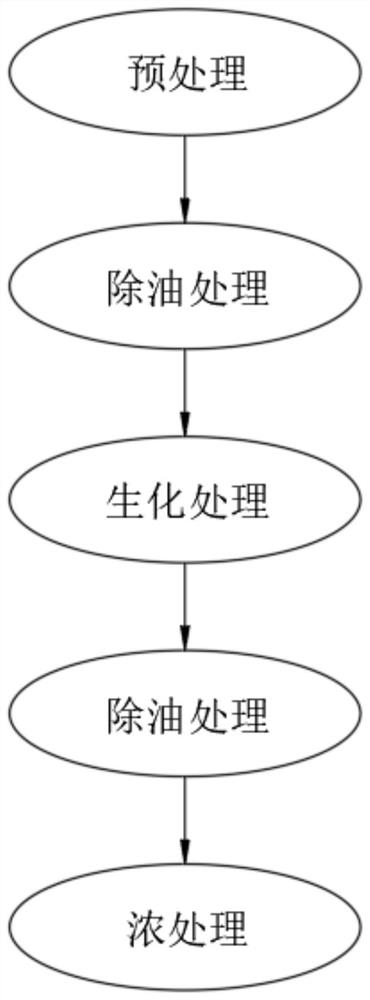

[0023] see figure 1 , the present invention provides the following technical solutions: a process for the treatment of phenol-containing wastewater of a coal chemical enterprise, wherein phenol refers to industrial phenol, comprising the following steps:

[0024] S1. Pretreatment: Initiate reaction, polycondensation reaction, strengthening reaction and precipitation separation of wastewater in sequence;

[0025] S1.1. Initiation reaction: Add initiator oxalic acid to high-concentration phenol-containing wastewater to initiate phenolic polycondensation reaction. The ratio of the dosage of initiator oxalic acid to the influent water is 10%, so that the pH value is 2, while maintaining the operation The temperature is 25°C, and the residence time is 0.6h;

[0026] S1.2. Polycondensation reaction: Add formaldehyde solution and hypochlorous acid catalyst, wherein the mass ratio of hypochlorous acid catalyst to formaldehyde solution is 0.05%, the residence time of the enhanced reac...

Embodiment 2

[0033] see figure 1 , the present invention provides the following technical solutions: a process for the treatment of phenol-containing wastewater of a coal chemical enterprise, wherein phenol refers to phenol, cresol and xylenol, comprising the following steps:

[0034] S1. Pretreatment: Initiate reaction, polycondensation reaction, strengthening reaction and precipitation separation of wastewater in sequence;

[0035] S1.1. Initiation reaction: add initiator citric acid to high-concentration phenol-containing wastewater to initiate phenolic polycondensation reaction, wherein the dosage of initiator citric acid is 9% to the mass ratio of influent, so that the pH value is 4, and at the same time Maintain the operating temperature at 40°C with a residence time of 0.8h;

[0036] S1.2. Polycondensation reaction: Add formaldehyde solution and aluminum trichloride catalyst, wherein the mass ratio of aluminum trichloride catalyst to formaldehyde solution is 0.06%, the residence ti...

Embodiment 3

[0043] see figure 1 , the present invention provides the following technical solutions: a process for the treatment of phenol-containing wastewater of a coal chemical enterprise, wherein phenol refers to alkylphenol and aralkylphenol, comprising the following steps:

[0044] S1. Pretreatment: Initiate reaction, polycondensation reaction, strengthening reaction and precipitation separation of wastewater in sequence;

[0045] S1.1. Initiation reaction: add initiator sulfuric acid to high-concentration phenol-containing wastewater, wherein the dosage of initiator sulfuric acid is 8% of the mass ratio of influent, trigger phenolic polycondensation reaction, make the pH value 5, and maintain the operation at the same time The temperature is 50°C, and the residence time is 0.9h;

[0046] S1.2. Polycondensation reaction: Add formaldehyde solution and hydrochloric acid catalyst, wherein the mass ratio of hydrochloric acid catalyst to formaldehyde solution is 0.02%, the residence time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com