Tea leaf conveyor convenient to disassemble and assemble and capable of automatically scraping out tea dust

A technology that facilitates disassembly and assembly of conveyors. It is applied in the directions of conveyors, conveyor objects, cleaning methods and utensils. It can solve the problems of low manual transfer efficiency, reduced performance, and large workload, so as to improve work efficiency and use. performance, improve performance, reduce the effect of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

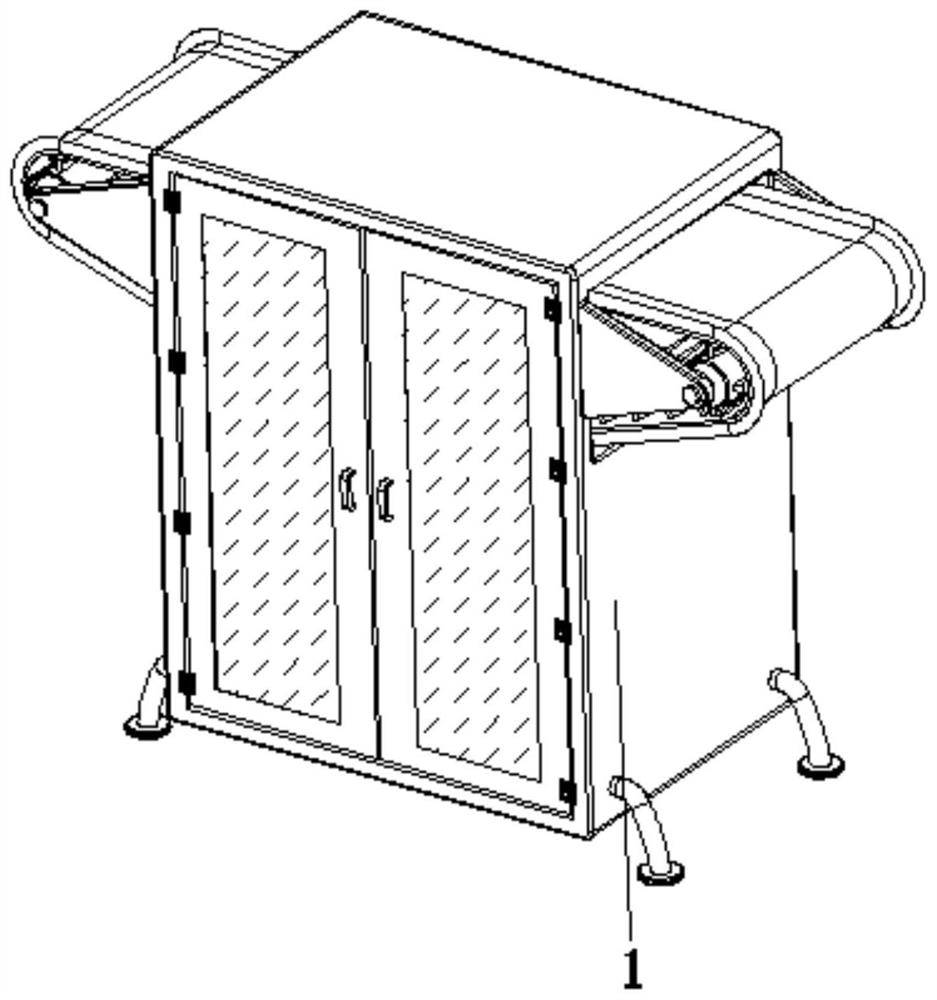

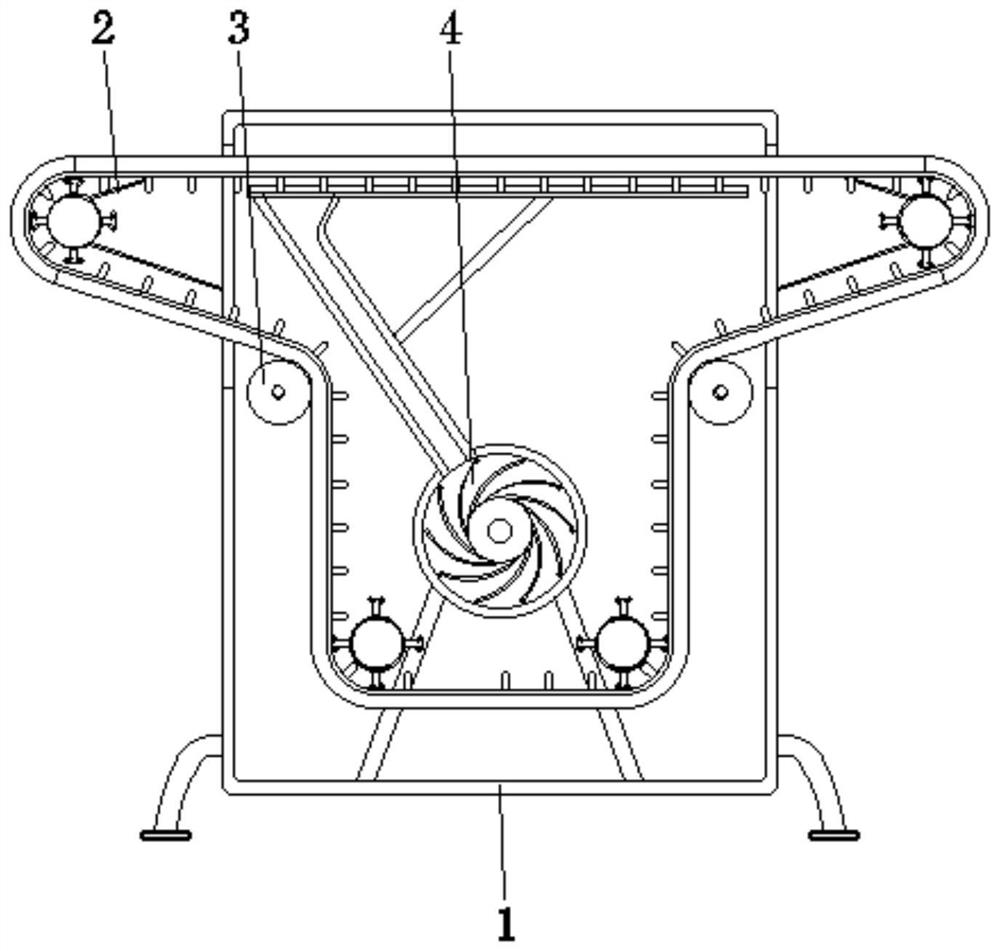

[0031] see Figure 1-7 , the present invention provides a technical solution: a tea conveyor for convenient disassembly and automatic scraping of tea dust, including a box body 1, a conveying device 2, a guide roller 3, and a slag collecting device 4, and the conveying device 2 is arranged on the box body 1, the end of the guide roller 3 is rotatably connected between the two sides corresponding to the inner wall of the box body 1, the surface of the guide roller 3 is closely attached to the surface of the conveying device 2, and the slag collecting device 4 is installed in the box body 1 and located at the position of the conveying device 2;

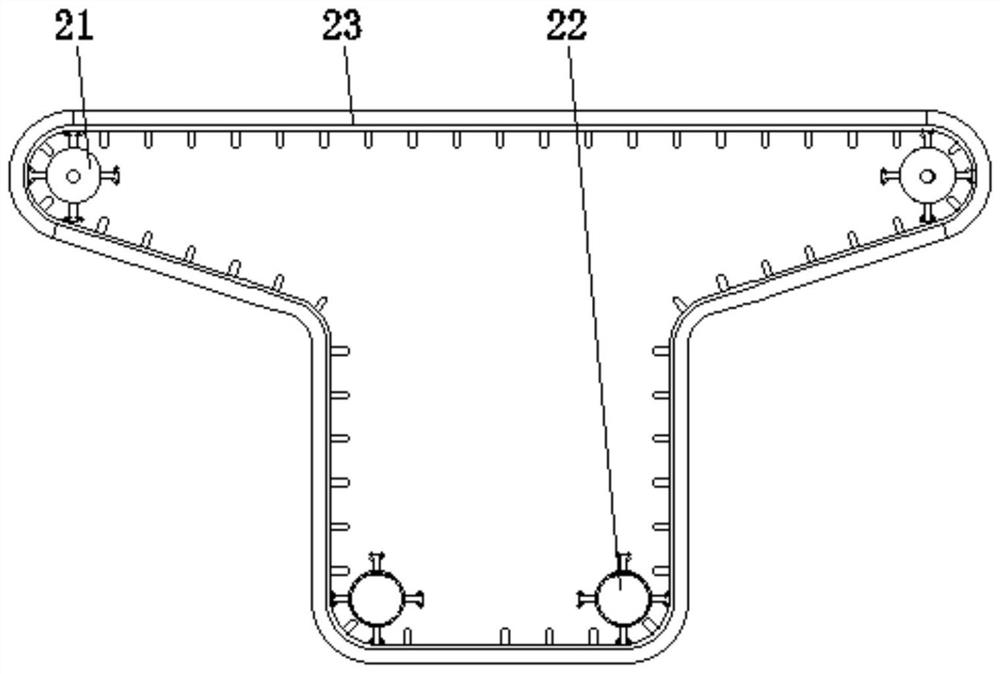

[0032] The conveying device 2 is provided with a driven support roller 21, a driving support roller 22, and a conveyor belt device 23. The end of the driven support roller 21 is rotationally connected with the top of the box body 1, and the driving support roller 22 is arranged on the top of the box body 1. Inside and close to the bott...

Embodiment example 2

[0034]The conveyor belt device 23 is provided with a conveyor belt 231, a strip skirt 232, a flexible filter screen 233, a top bar device 234, and a vibrating device 235. The conveyor belt 231 is arranged on the surface of the driven support roller 21 and the driving support roller 22, and the strip skirt 232 It is fixedly connected with the top of the surface of the conveyor belt 231 and is located at the edge position, the surface edge of the flexible filter screen 233 is fixedly connected with the surface edge of the conveyor belt 231, the top bar device 234 is arranged on the inner wall of the conveyor belt 231, and the vibrating device 235 is arranged on the inner wall of the conveyor belt 231 And close to the position of the top bar device 234, the conveyor belt 231 is used to drive the flexible filter screen 233 through the active support roller 22. At this time, the top bar device 234 will move thereupon, and the flexible filter screen 233 will be moved by the action of ...

Embodiment example 3

[0036] The top bar device 234 is provided with a top bar body 2341, a ball 2342, and a scraper 2343. The top of the top bar body 2341 is fixedly connected to the inner wall of the conveyor belt 231. 2343 is fixed at the bottom of the top bar body 2341. When the conveyor belt 231 drives the top bar body 2341 to move, the balls 2342 will roll on the top of the receiving plate groove 42 to reduce friction and prevent jamming , so that the movement is smoother, and the top bar body 2341 is driven to lift the conveyor belt 231 and the flexible filter screen 233 in time by using the arc surface protrusion 43, and through vibration, the cleaning of impurities is promoted, and the scraper 2343 will follow the top bar body 2341 move together to scrape off the impurities falling into the material receiving plate groove 42, which promotes the cleaning of impurities and makes the tea quality high.

[0037] The vibration device 235 is provided with a base block 2351, a connecting spring 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com