Jelly with various tastes and preparation method thereof

A taste and jelly technology, applied in the field of jelly preparation, jelly and its preparation, can solve the problems of low nutritional content, children's intellectual development is not well promoted, etc., achieves low EPA content, improves night blindness, and is conducive to absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

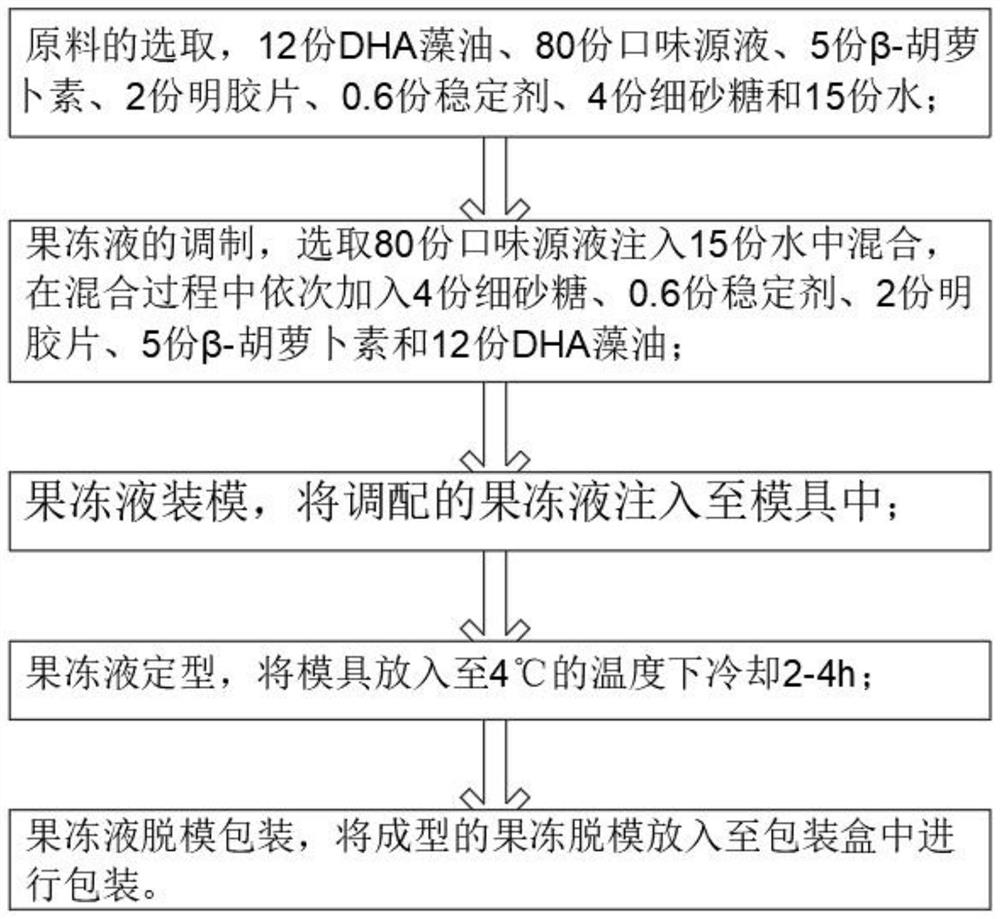

[0031] The jelly preparation method includes the following steps:

[0032] S1: Selection of raw materials, 12 parts of DHA algae oil, 80 parts of flavor source liquid, 5 parts of beta-carotene, 2 parts of gelatin sheets, 0.6 parts of stabilizer, 4 parts of caster sugar and 15 parts of water;

[0033] S2: Preparation of jelly liquid, select 80 parts of flavor source liquid and pour it into 15 parts of water to mix, and add 4 parts of fine sugar, 0.6 parts of stabilizer, 2 parts of gelatin film, 5 parts of B-carotene and 12 parts of DHA in sequence during the mixing process algal oil;

[0034] S3: The jelly liquid is installed into the mold, and the prepared jelly liquid is injected into the mold;

[0035] S4: The jelly liquid is shaped, and the mold is cooled at a temperature of 4°C for 2-4h;

[0036] S5: The jelly liquid is demolded and packaged, and the formed jelly is demolded and put into a packaging box for packaging.

[0037] The taste source solution can be at least o...

Embodiment 1

[0048] Preparation of apple-flavored jelly:

[0049] S1: Selection of raw materials, 12 parts of DHA algal oil, 80 parts of apple source liquid, 5 parts of beta-carotene, 2 parts of gelatin sheets, 0.6 parts of stabilizer, 4 parts of caster sugar and 15 parts of water;

[0050] S2: Preparation of jelly liquid, select 80 parts of apple source liquid and pour it into 15 parts of water to mix, and add 4 parts of fine sugar, 0.6 parts of stabilizer, 2 parts of gelatin film, 5 parts of β-carotene and 12 parts of DHA in sequence during the mixing process Algae oil, the mixing time is controlled for 30-45min;

[0051] S3: The jelly liquid is installed into the mold, and the prepared jelly liquid is injected into the mold;

[0052] S4: The jelly liquid is shaped, and the mold is cooled at a temperature of 4°C for 2-4h;

[0053] S5: The jelly liquid is demolded and packaged, and the formed jelly is demolded and put into a packaging box for packaging.

[0054] Beneficial effects: the...

Embodiment 2

[0056] Preparation of blueberry flavored jelly:

[0057] S1: Selection of raw materials, 10 parts of DHA algal oil, 85 parts of blueberry source liquid, 7 parts of beta-carotene, 1 part of gelatin sheet, 0.7 parts of stabilizer, 5 parts of caster sugar and 16 parts of water;

[0058]S2: Preparation of jelly liquid, select 85 parts of blueberry source solution and pour it into 16 parts of water to mix, and add 5 parts of fine sugar, 0.7 parts of stabilizer, 1 part of gelatin film, 7 parts of β-carotene and 10 parts of DHA in sequence during the mixing process Algae oil, the mixing time is controlled for 40-45min;

[0059] S3: The jelly liquid is installed into the mold, and the prepared jelly liquid is injected into the mold;

[0060] S4: The jelly liquid is shaped, and the mold is cooled at a temperature of 4°C for 2-4h;

[0061] S5: The jelly liquid is demolded and packaged, and the formed jelly is demolded and put into a packaging box for packaging.

[0062] Beneficial ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com