Fresh shrimp freeze-sleeping technology

A technology of fresh shrimp and technology, applied in the direction of freezing/cooling preservation of meat/fish, food ingredients containing natural extracts, food science, etc., can solve the problems of fresh shrimp quality and nutritional value deterioration, affecting the quality of fresh shrimp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

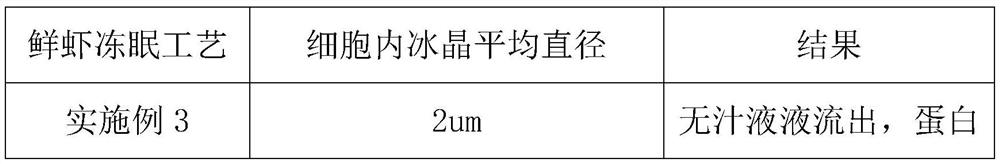

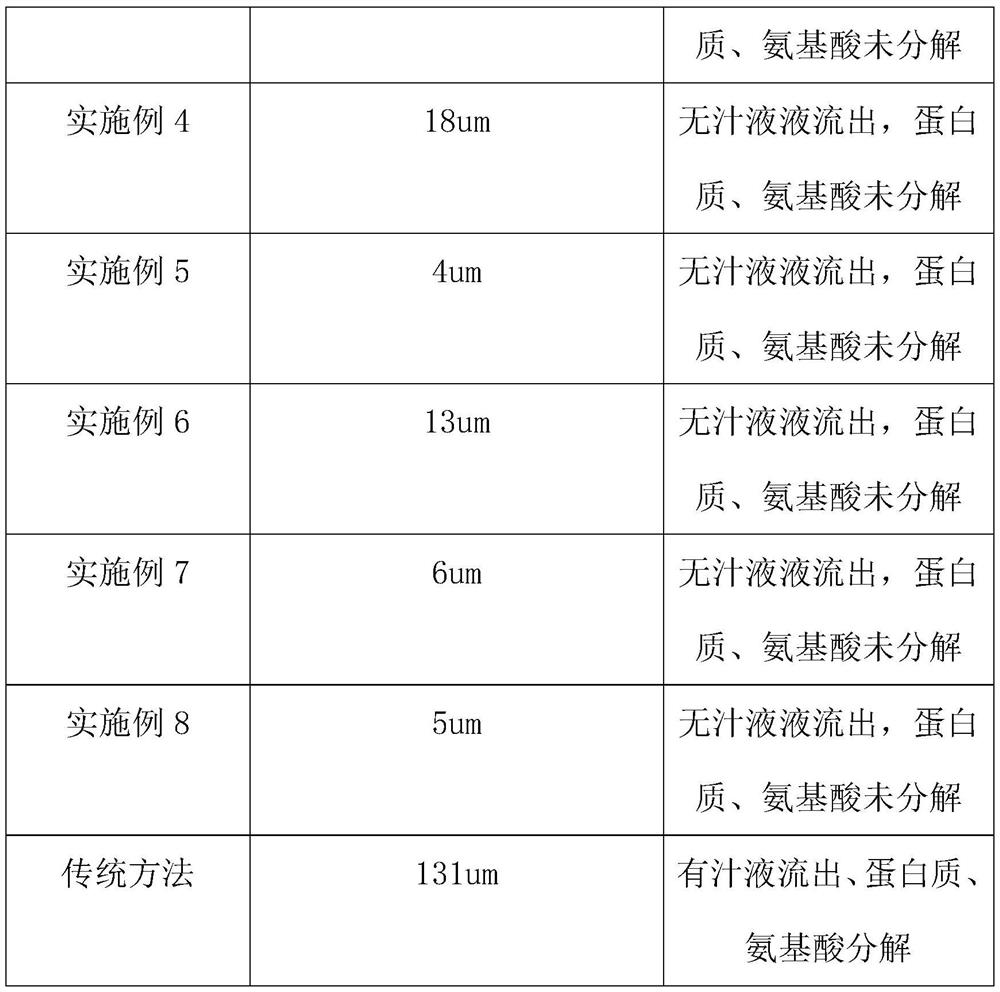

Examples

Embodiment 1

[0058] A cryopreservation process for fresh shrimps. The fresh shrimps are soaked in a cryopreservation solution, and the temperature and the intensity of microwave radiation are adjusted to perform the cryopreservation operation, so that the diameter of the ice crystals in the cells of the fresh shrimps is less than 20 μm.

[0059] Step 1. Soak the fresh shrimp in the freezing solution with an initial temperature below -10°C, and cool the freezing solution to T 1 , adjust the microwave radiation intensity K 1 Carry out microwave assisted irradiation, keep t 1 , and -18℃≤T 1 ≤-10℃, K 1 ≥100μW / cm 2 , t 1 ≥3min.

[0060] Step 2: Make the temperature of the freezing solution be T 2 , adjust the microwave radiation intensity K 3 Carry out microwave assisted irradiation, keep t 3 , and -18℃≤T 2 ≤-35℃, K 2 ≥200μW / cm 2 , t 2 ≥5min.

[0061] Step 3: Make the temperature of the freezing solution be T 3 , turn off the microwave radiation, keep t 3 , and -20℃≤T 3 ≤-25°C, ...

Embodiment 2

[0079] A cryopreservation process for fresh shrimps. The fresh shrimps are soaked in a cryopreservation solution, and the temperature and the intensity of microwave radiation are adjusted to perform the cryopreservation operation, so that the diameter of the ice crystals in the cells of the fresh shrimps is less than 20 μm.

[0080] Step 1. Soak the fresh shrimp in the freezing solution with an initial temperature below -10°C, and cool the freezing solution to T 1 , adjust the microwave radiation intensity K 1 Carry out microwave assisted irradiation, keep t 1 , and -15℃≤T 1 ≤-12℃, 180μW / cm 2 ≥K 1 ≥150μW / cm 2 , 5min≥t 1 ≥4min.

[0081] Step 2: Make the temperature of the freezing solution be T 2 , adjust the microwave radiation intensity K 3 Carry out microwave assisted irradiation, keep t 3 , and -13℃≤T 2 ≤-33℃, 350μW / cm 2 ≥K 2 ≥220μW / cm 2 , 18min≥t 2 ≥6min.

[0082] Step 3: Make the temperature of the freezing solution be T 3 , turn off the microwave radiatio...

Embodiment 3

[0096] A cryopreservation process for fresh shrimps. The fresh shrimps are soaked in a cryopreservation solution, and the temperature and the intensity of microwave radiation are adjusted to perform the cryopreservation operation, so that the diameter of the ice crystals in the cells of the fresh shrimps is less than 20 μm.

[0097] Step 1. Soak the fresh shrimp in the freezing solution with an initial temperature below -10°C, and cool the freezing solution to T 1 , adjust the microwave radiation intensity K 1 Carry out microwave assisted irradiation, keep t 1 , and -18℃≤T 1 ≤-10℃, K 1 168μW / cm 2 , t 1 4.5min.

[0098]Step 2: Make the temperature of the freezing solution be T 2 , adjust the microwave radiation intensity K 3 Carry out microwave assisted irradiation, keep t 3 , and -18℃≤T 2 ≤-35℃, K 2 280μW / cm 2 , t 2 10min.

[0099] Step 3: Make the temperature of the freezing solution be T 3 , turn off the microwave radiation, keep t 3 , and -20℃≤T 3 ≤-25°C, t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com