All-electric aerial work platform energy recovery control system and method

An aerial work platform and energy recovery technology, which is applied in electric vehicles, circuit monitoring/indication, safety/protection circuits, etc., to achieve the effects of optimizing the installed capacity of the whole machine, improving the utilization rate of electric energy, and improving the efficiency of energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

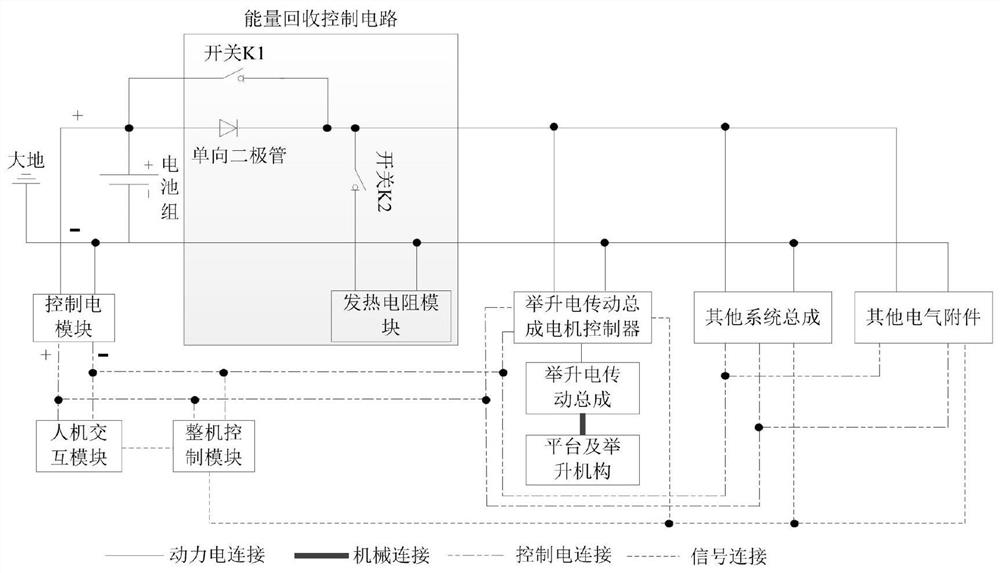

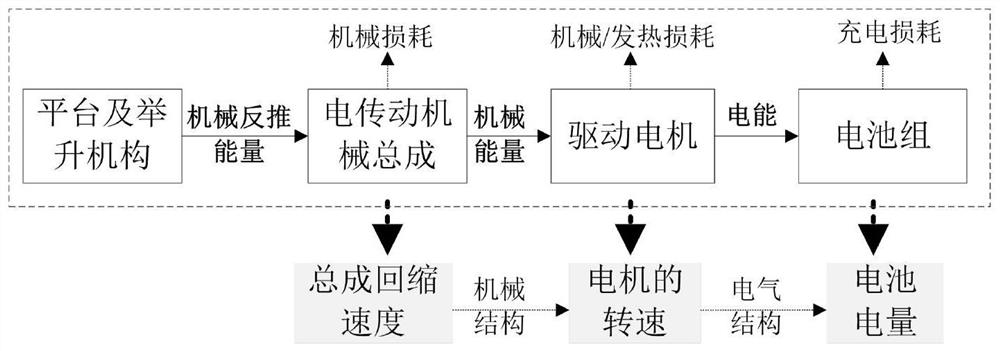

[0072] Such as figure 1 As shown, this embodiment provides an all-electric aerial work platform energy recovery control system, including a battery pack, an energy recovery control circuit connected to the battery pack, a control electrical module, and a motor controller for a lifting electric transmission assembly , other system assemblies and other electrical accessories; the control system also includes a human-computer interaction module, a complete machine control module, a lifting electric transmission assembly, a platform and a lifting mechanism, and the lifting electric transmission assembly and the lifting The motor controller of the electric transmission assembly is electrically connected to the power, and the lifting electric transmission assembly is mechanically connected to the platform and the lifting mechanism; the control electric module is respectively connected to the human-computer interaction module, the whole machine control control electrical connection t...

Embodiment 2

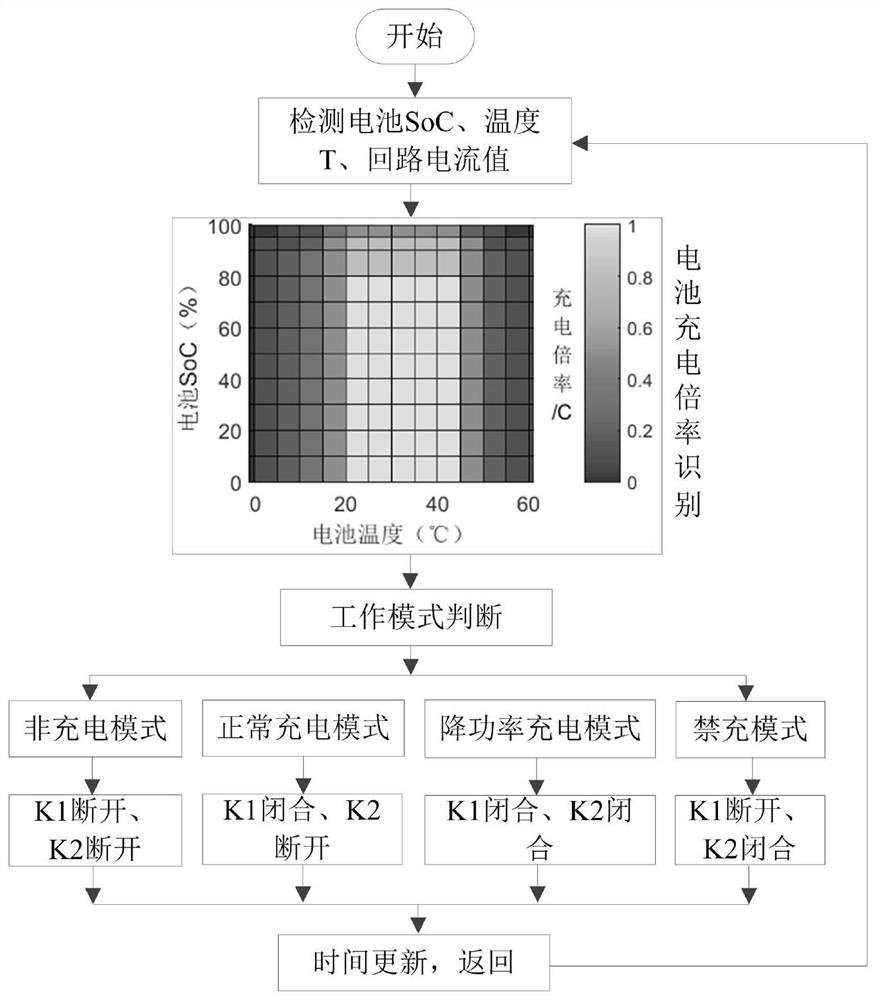

[0112] Such as image 3 As shown, this embodiment provides an energy recovery control method for an all-electric aerial work platform, including the following steps:

[0113] S1, detecting the state parameters of the battery pack and the platform power generation parameters at time t;

[0114] S2, switch the working mode of the battery pack through the energy recovery control circuit according to the current state parameters of the battery pack and the platform power generation parameters;

[0115] S3, update the system time, t=t+1, return to step S1, and execute steps S1 to S3 in a loop until the system shuts down.

[0116] Specifically, the energy recovery control circuit includes a one-way diode, a switch K1, a switch K2, and a heating resistor module. two ends of the diode; the switch K2 is connected in series with the heating resistor module and connected in parallel with the motor controller of the lift electric transmission assembly; the energy recovery control circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com