Preparation method and application of precursor of aluminum and zirconium doped lithium nickelate positive electrode material

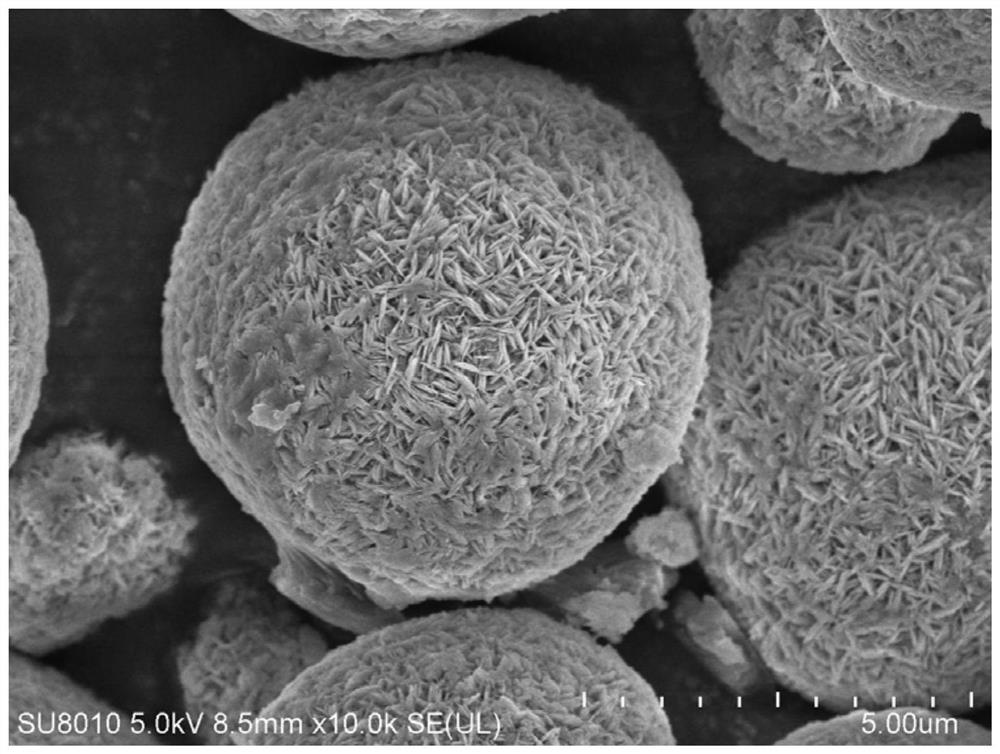

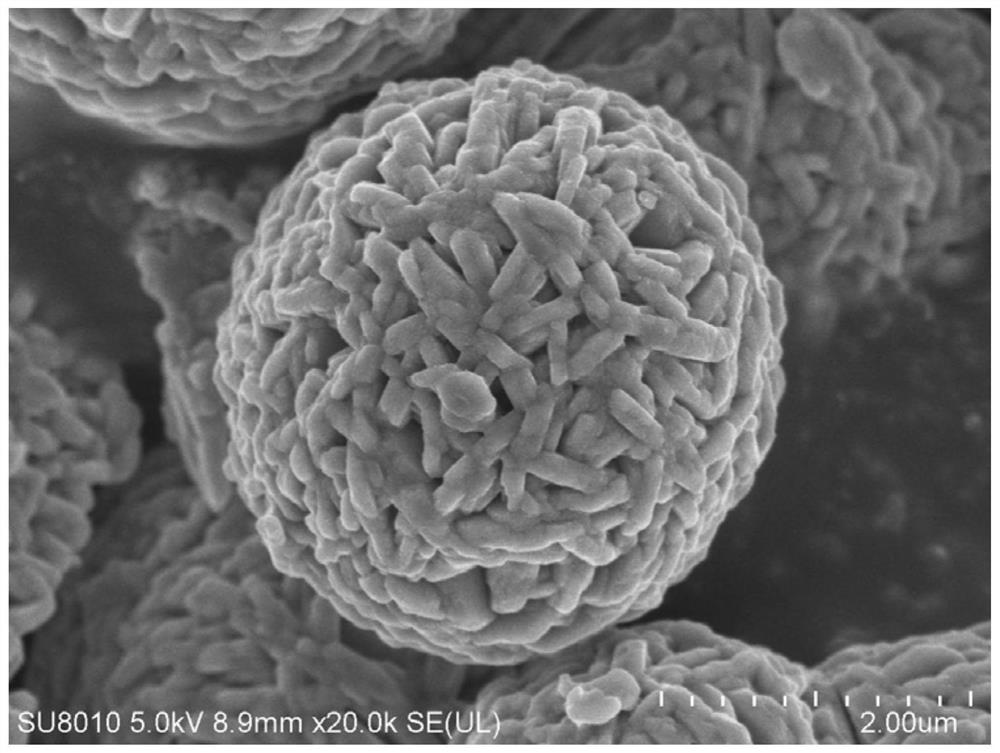

A positive electrode material and precursor technology, applied in the field of precursor preparation, can solve the problem that the precursor cannot be uniformly dispersed, and achieve the effect of uniform distribution of internal elements, high tap density, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

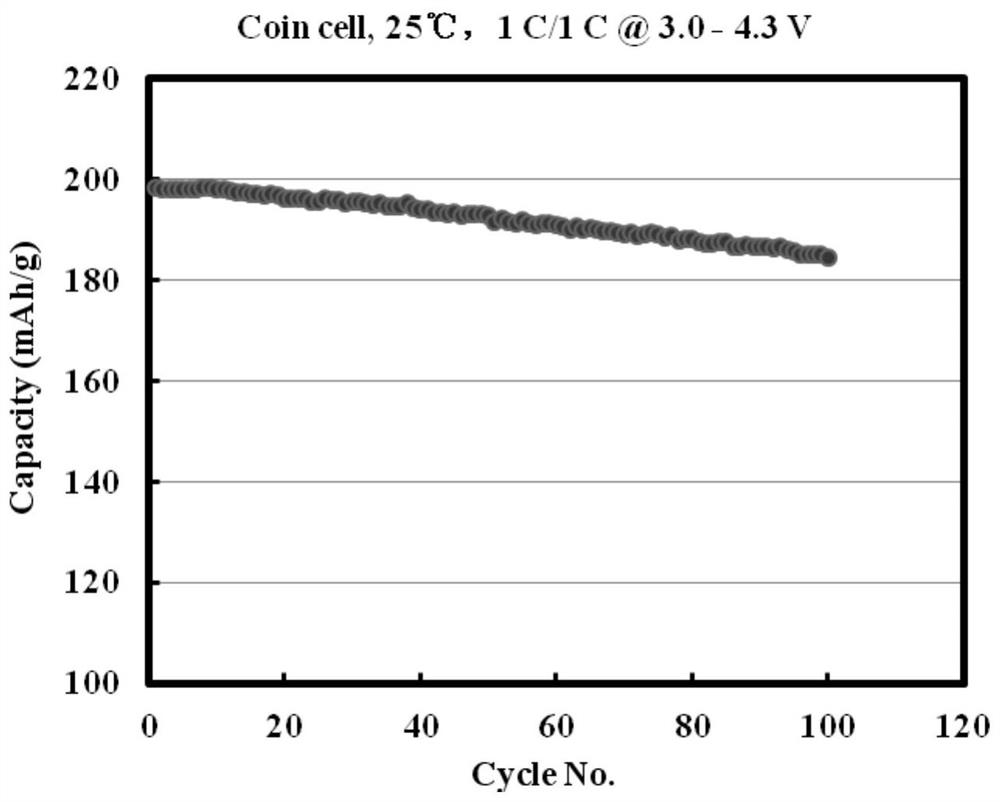

[0033] Example 1 Preparation method and application of a precursor of aluminum and zirconium doped lithium nickelate positive electrode material

[0034] The implementation of the present invention provides a precursor for preparing aluminum, zirconium doped lithium nickelate positive electrode material and a method for preparing aluminum, zirconium doped lithium nickelate positive electrode material using the precursor, which comprises the following steps:

[0035] Step 1, configuring a mixed salt solution with a nickel ion concentration of 2mol / L and a zirconium ion concentration of 0.003mol / L;

[0036] Step 2, taking an appropriate amount of aluminum sulfate hexadecahydrate and adding it to a sodium hydroxide solution with a concentration of 4.5 mol / L to form a 0.1 mol / L sodium metaaluminate mixed solution;

[0037] Step 3. Add the mixed salt solution, sodium metaaluminate mixed solution and ammonia solution into a 55°C constant temperature stirring synthesis tank with a ma...

Embodiment 2

[0045] Example 2 Preparation method and application of a precursor of aluminum and zirconium doped lithium nickelate positive electrode material

[0046]The implementation of the present invention provides a precursor for preparing aluminum, zirconium doped lithium nickelate positive electrode material and a method for preparing aluminum, zirconium doped lithium nickelate positive electrode material using the precursor, which comprises the following steps:

[0047] Step 1, configure the mixed salt solution whose nickel ion concentration is 2mol / L and zirconium ion concentration is 0.004mol / L;

[0048] Step 2, taking an appropriate amount of aluminum nitrate nonahydrate and adding it to a sodium hydroxide solution with a concentration of 4.5mol / L to form a 0.1mol / L sodium metaaluminate mixed solution;

[0049] Step 3. Add the mixed salt solution, sodium metaaluminate mixed solution and ammonia solution into a 50°C constant temperature stirring synthesis tank with a mass concent...

Embodiment 3

[0057] Example 3 Preparation method and application of a precursor of aluminum and zirconium doped lithium nickelate cathode material

[0058] The implementation of the present invention provides a precursor for preparing aluminum, zirconium doped lithium nickelate positive electrode material and a method for preparing aluminum, zirconium doped lithium nickelate positive electrode material using the precursor, which comprises the following steps:

[0059] The implementation of the present invention provides a method for preparing aluminum, zirconium-doped spherical lithium nickelate positive electrode material and special precursor thereof, which comprises the following steps:

[0060] Step 1, configuring a mixed salt solution with a nickel ion concentration of 1.75mol / L and a zirconium ion concentration of 0.0025mol / L;

[0061] Step 2, taking an appropriate amount of aluminum nitrate nonahydrate and adding it to a sodium hydroxide solution with a concentration of 4mol / L to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com