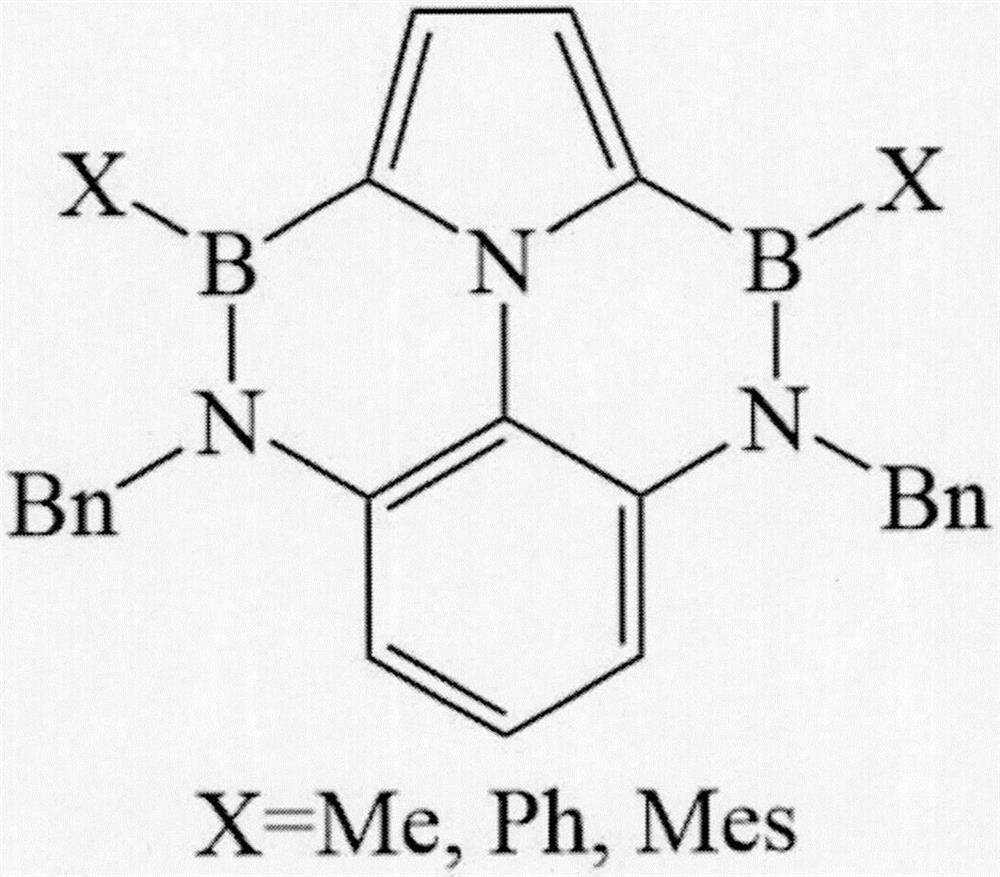

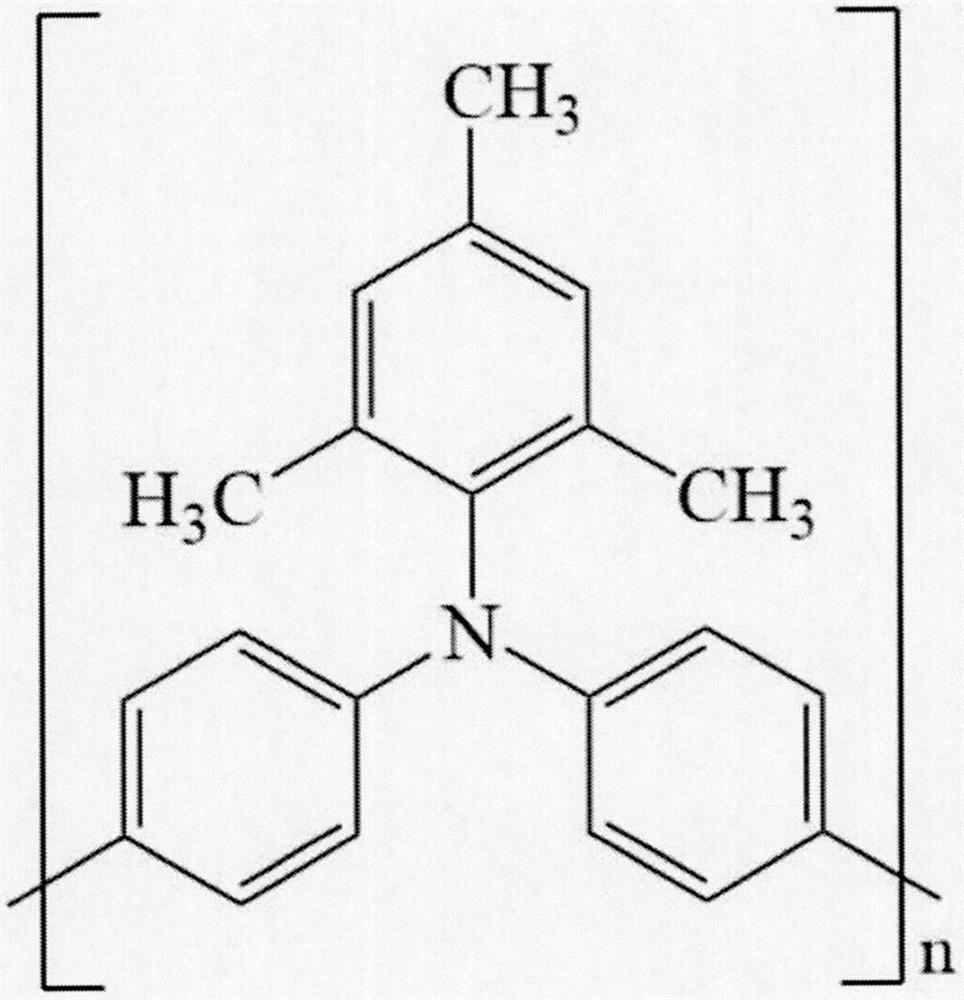

Preparation method of ultra-low turn-on voltage deep blue light organic electroluminescent device

A lighting-on voltage and luminescence technology, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complicated process and expensive preparation cost, achieve simple preparation process, increase fluorescence intensity, improve color The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

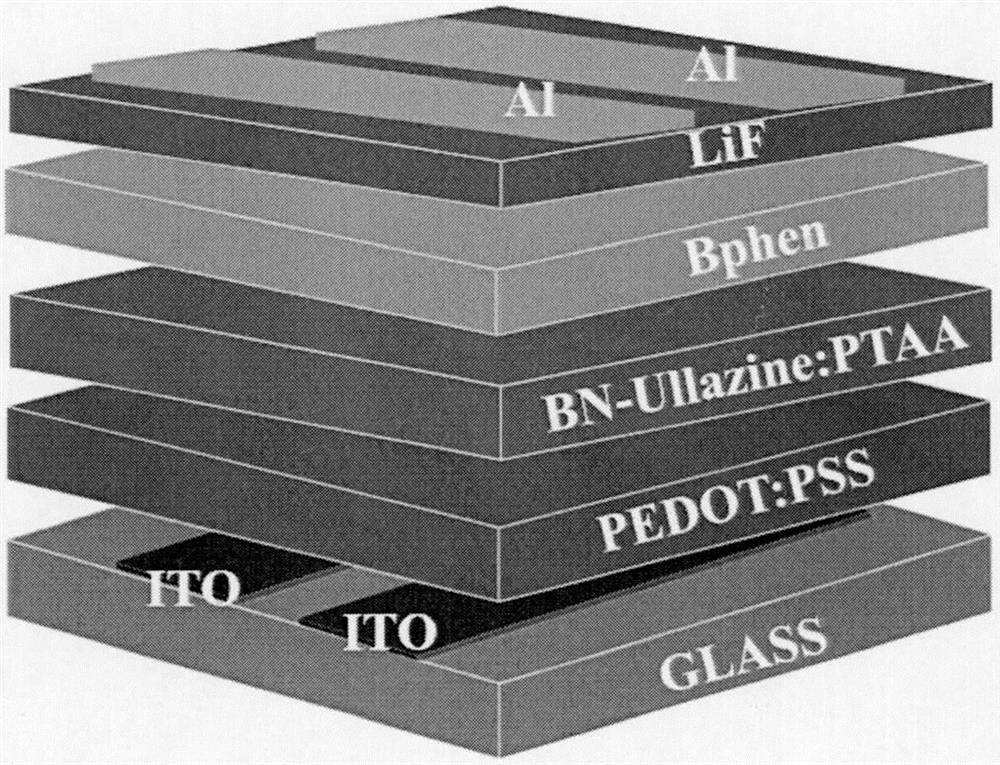

[0042] The structural schematic diagram of the ultra-low turn-on voltage deep blue OLED device described in the present invention is as follows figure 2 shown. It can be seen from the figure that the structure of the ultra-low turn-on voltage deep blue OLED device is sequentially from the lower layer to the upper layer: a transparent conductive anode, a hole transport layer, a mixed light emitting layer, an electron transport layer, an electron buffer layer and a metal cathode. The structure of the prepared doped light-emitting device is:

[0043] Device 1: ITO / PEDOT:PSS / BN-Ullazine-a:PTAA / Bphen / LiF / Al

[0044] Device 2: ITO / PEDOT:PSS / BN-Ullazine-b:PTAA / Bphen / LiF / Al

[0045] Device 3: ITO / PEDOT:PSS / BN-Ullazine-c:PTAA / Bphen / LiF / Al

[0046] The preparation process of the deep blue OLED device comprises the following steps:

[0047] (1) The ITO glass substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water for 20 minutes in sequence, and then dried ...

Embodiment 2

[0056] (1) Utilize 3-2-IHR221-NIR-TCSPC steady-state-transient fluorescence spectrometer to carry out photoluminescence spectrum (PL) test to BN-Ullazine derivative thin film and PTAA thin film spin-coated on ITO substrate respectively, as image 3 shown. It can be seen from the test results that the PL peak positions of the three BN-Ullazine derivative films whose substituents are methyl, trimethylphenyl, and phenyl are 358nm, 385nm, and 390nm in turn, and the PL peak positions of the PTAA film are about 420nm.

[0057] (2) Under vacuum conditions, use 3-2-IHR221-NIR-TCSPC steady-state-transient fluorescence spectrometer and Cryocooler cryostat to perform PL spectroscopy on BN-Ullazine derivative thin films at low temperature (77K) in liquid nitrogen test, such as Figure 4 shown. It can be seen from the test results that the PL spectra of the three BN-Ullazine derivative films broadened at low temperature, and new shoulder peaks appeared at 2.63eV, 2.61eV and 2.62eV, resp...

Embodiment 3

[0059] Luminescence performance tests were carried out on OLED devices 1-4, and the test results are summarized in Table 1.

[0060] Such as Figure 5 Shown are the EL spectra of OLED devices 1-4 of the present invention, and the EL peaks of devices 1-4 are all at 420 nm.

[0061] Such as Figure 6 Shown is the J-V-L characteristic curve of OLED device 1-4 of the present invention;

[0062] Such as Figure 7 Shown is the CE-J-PE characteristic curve of OLED device 1-4 of the present invention;

[0063] Such as Figure 8 Shown is a schematic diagram of the energy level of the OLED device of the present invention and the principle of light emission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com