Method for rapidly detecting solidification tail end position of continuous casting billet

A technology of solidification end and continuous casting slab, which is applied in the preparation of test samples, the configuration of indicating equipment/measuring equipment, sampling devices, etc., and can solve the problems of many external influence factors, high risk, difficult transportation, procurement, etc. , to achieve the effects of strong operability, simple process flow and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

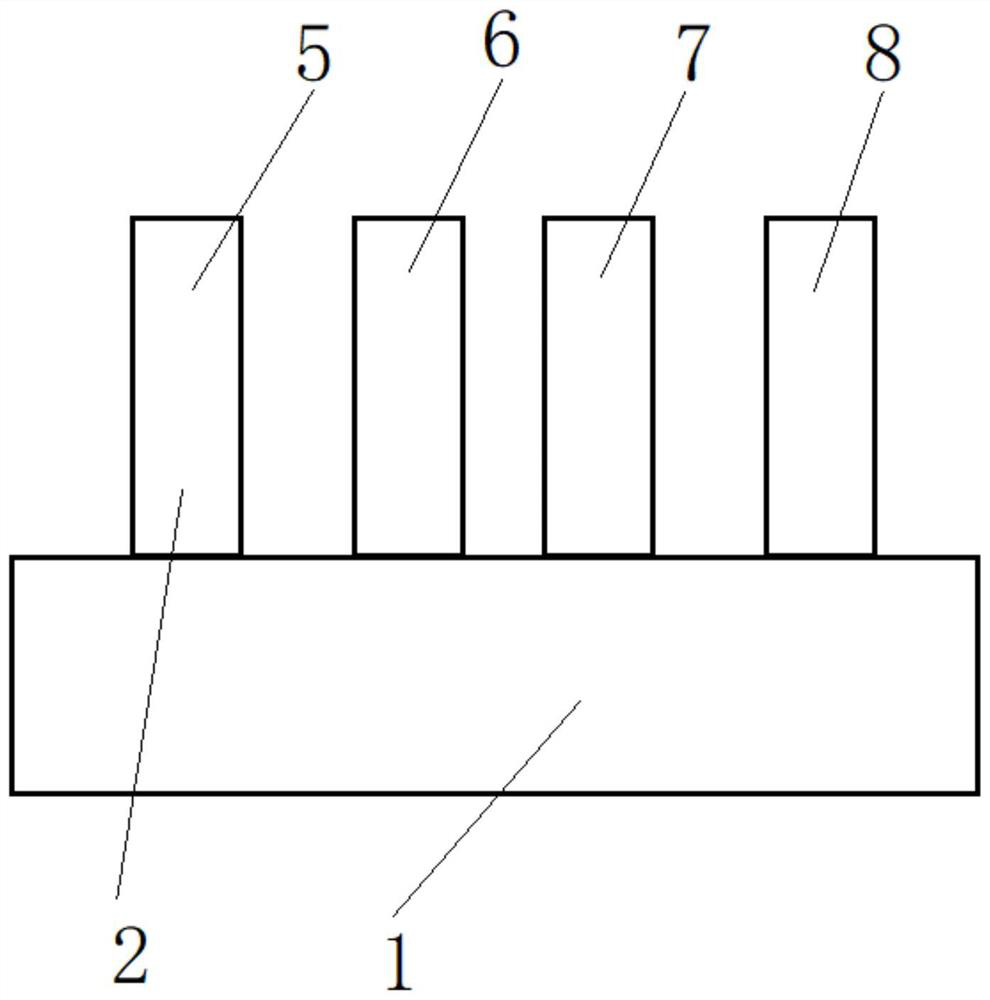

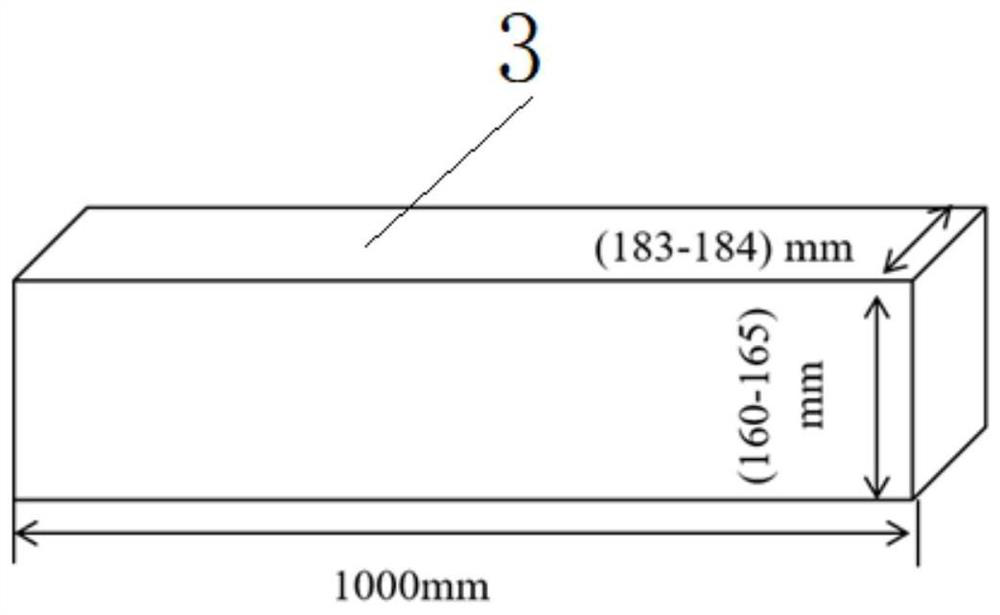

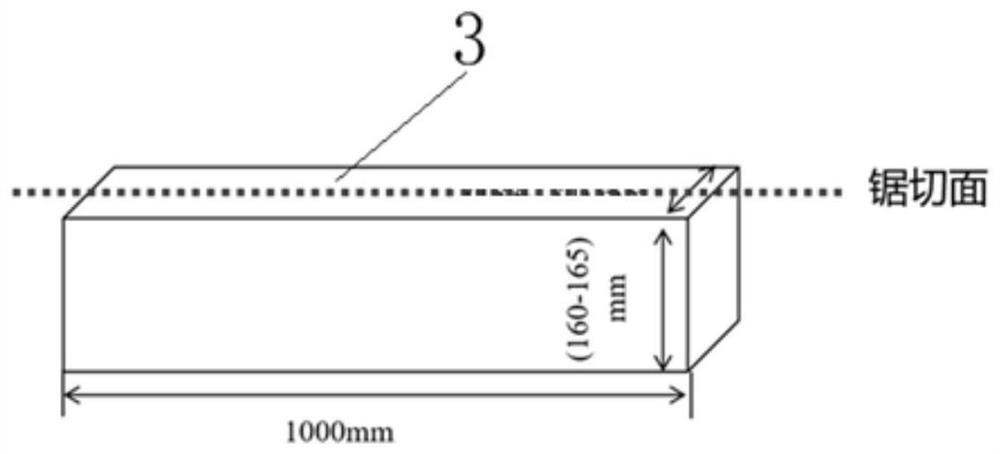

[0029] as attached figure 1 - attached Figure 4As shown, the present invention is a method for quickly detecting the solidification end position of a continuous casting slab, and the detection steps of the method for rapidly detecting the solidification end position of a continuous casting slab are: S1. Multiple rollers 2 of the leveling machine 1 sequentially press down the continuous casting slab, and the rollers 2 apply pressure in the direction of the inner and outer arcs of the continuous casting slab during the pressing; S2. The continuous casting slab after each roller 2 is pressed is respectively cut and take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com