Construction method of tunnel structure for manual and mechanical combined obstacle removal of water-rich sand layer

A water-rich sand layer and tunnel structure technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficulty in ensuring engineering safety and personnel safety, unsuitable uplift piles, and low stability of sand layers, achieving Ensure long-distance freezing effect, improve passability, and freeze the effect of small range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

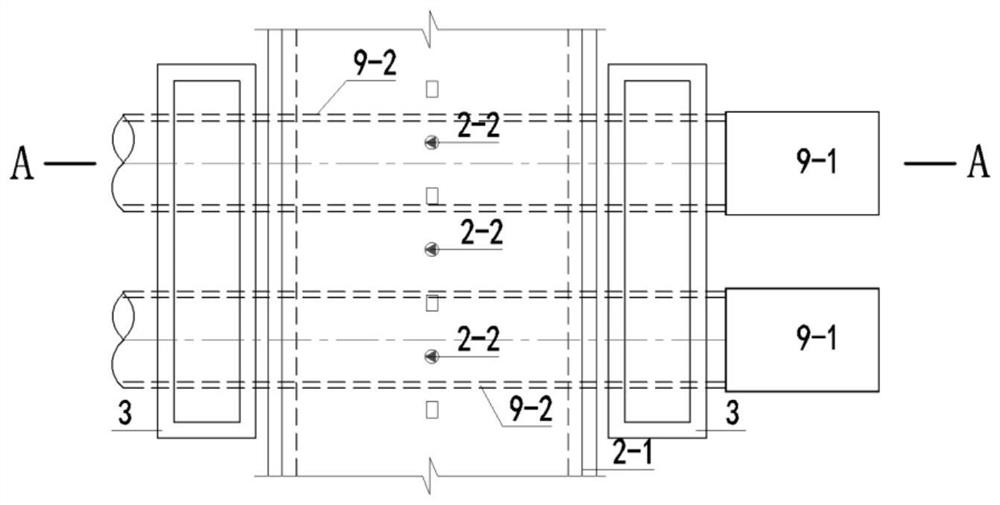

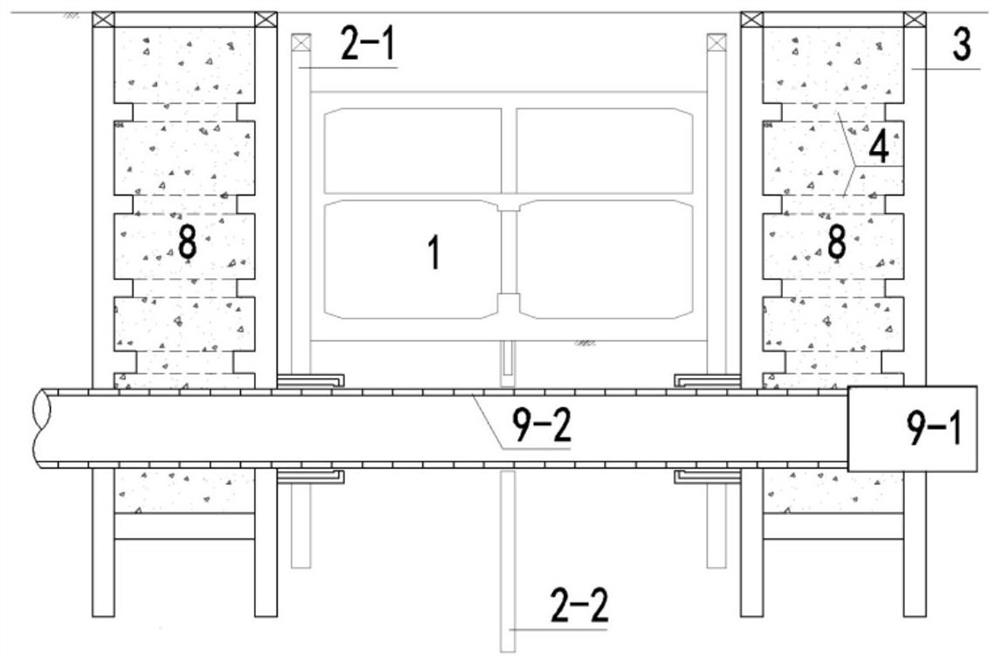

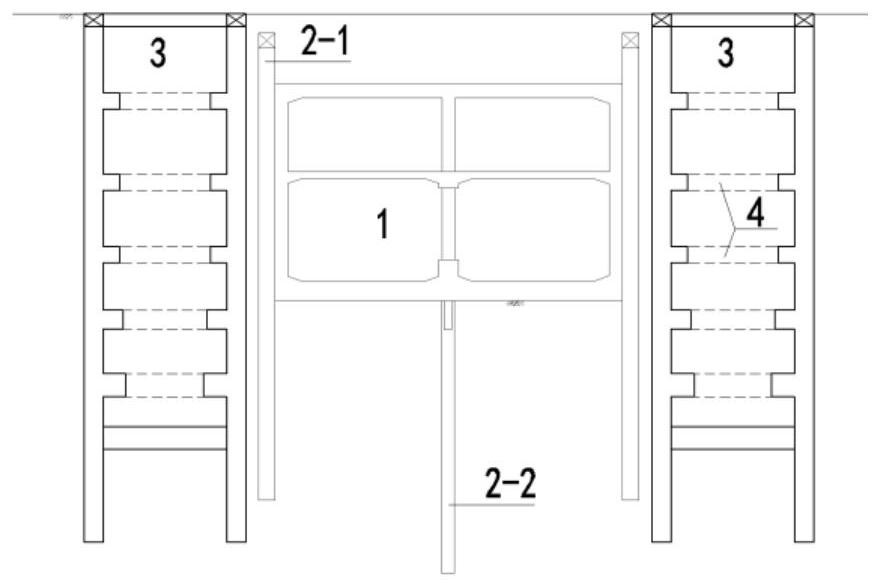

[0040] Such as Figure 3-10 As shown in the present invention, a construction method for a tunnel structure with artificial mechanical combination of water-rich sand layers, comprising the following steps: constructing the ground shafts 3 on both sides of the existing underground station 1, and performing horizontal freezing from the inside of the ground shafts 3 on both sides And two closed and disconnected frozen wall structures 5-2 are formed in the existing underground station 1, and the frozen wall structures 5-2 are frozen by salt water to form a cylindrical reinforced soil body with a certain strength and water-stop performance. Support 6-1, remove the ground connection wall 2-1 of the underground obstacle within the shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com