Reinforcement cage circulating reinforcement hanging device and using method thereof

A technology of steel cages and suspending bars, applied in construction, infrastructure engineering and other directions, can solve problems such as affecting construction efficiency, and achieve the effects of improving construction efficiency, convenient removal, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

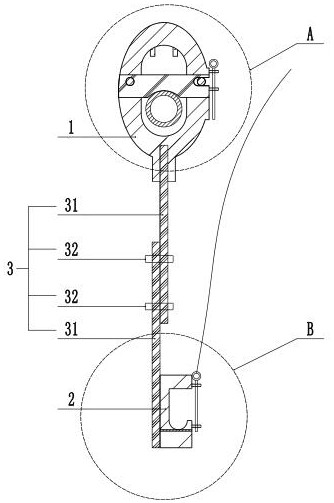

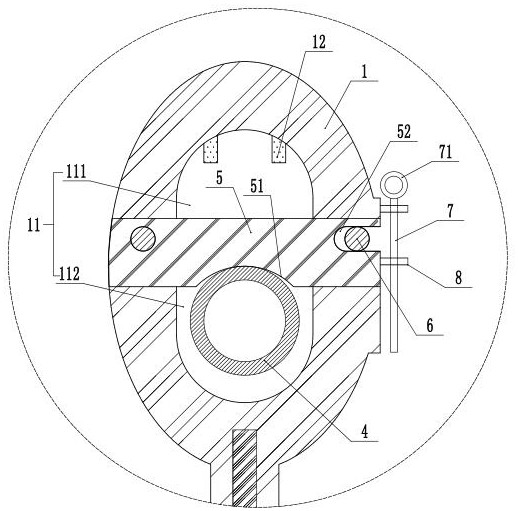

[0038] like figure 1 , figure 2 and image 3Shown, a kind of steel cage circulation hanger device in the present embodiment, comprises lifting part 1 and hanging part 2, is provided with connecting part 3 between described lifting part 1 and described hanging part 2, and described hanging part 2 uses In connection with the reinforcement cage, the hoisting part 1 is provided with a hanging space 11, the hanging space 11 is used to connect with the hoisting mechanism, the positioning rod 4 is pierced in the hanging space 11, and the positioning rod 4 can be lapped on the pile hole.

[0039] During use, the reinforcement cage is connected with the suspension part 2, and then the hook of the hoisting mechanism is moved into the suspension space 11 of the hoisting part 1 to realize the hoisting of the whole suspension device and the reinforcement cage on the hoisting mechanism. After the pile hole is hoisted in place, the positioning rod 4 is inserted in the hanging space 11, a...

Embodiment 2

[0046] like figure 1 and figure 2 As shown, in this embodiment, the difference from Embodiment 1 is that a positioning clamp 5 is provided on the lifting part, and the positioning clamp 5 divides the hanging space 11 into two sections, from top to bottom The bottom is followed by a hanging area 111 and a positioning area 112. The hanging area 111 is used to connect with the lifting mechanism, and the positioning area 112 is used to pass through the positioning rod 4. 11 Separate the two sections, so that there is no movement interference between the lifting mechanism hook and the positioning rod 4. After the steel cage is lowered in place, the positioning rod 4 can bear the gravity of the reinforcement cage, so that the lifting mechanism hook can be moved out of the suspension ring more easily. .

[0047] Further, the positioning clip 5 is provided with an arc-shaped slot 51 on one side close to the positioning bar 4, so that the positioning bar 4 can be snapped into the ar...

Embodiment 3

[0052] like figure 1 , figure 2 and image 3 As shown, this embodiment discloses a method for using hanging bars, using the above-mentioned a kind of reinforcement cage circulating hanging bar device, the steps are as follows:

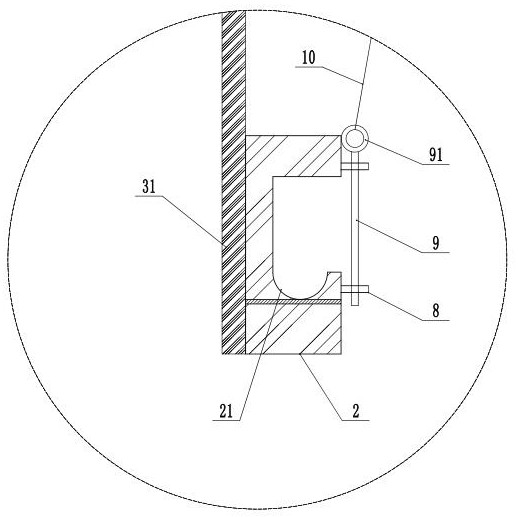

[0053] a. Snap the hook of the lifting mechanism into the hanging area 11 of the suspension ring, snap the reinforcement cage ring into the hanging groove 21 of the suspension block, and pass the second limit pin 9 through the two installation rings in turn 8. Limit the reinforcement cage in the hanging groove 21;

[0054] b. Start the lifting mechanism to hoist the reinforcement cage into the pile hole. After the reinforcement cage is hoisted in place, set the positioning rod 4 in the positioning area of the lifting ring, and continue the lower reinforcement cage through the lifting mechanism to make the two ends of the positioning rod 4 Overlap on both sides of the pile hole, and then move the hook of the lifting mechanism out of the hanging ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com