Production method of 3-methylthiophene and equipment

A technology for methylthiophene and production equipment, which is applied in the field of production methods and equipment for trimethylthiophene, can solve problems such as increased exhaust gas emissions, increased carbon dioxide, and low production capacity, and achieves less side reactions, safe production methods, and low reaction temperatures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

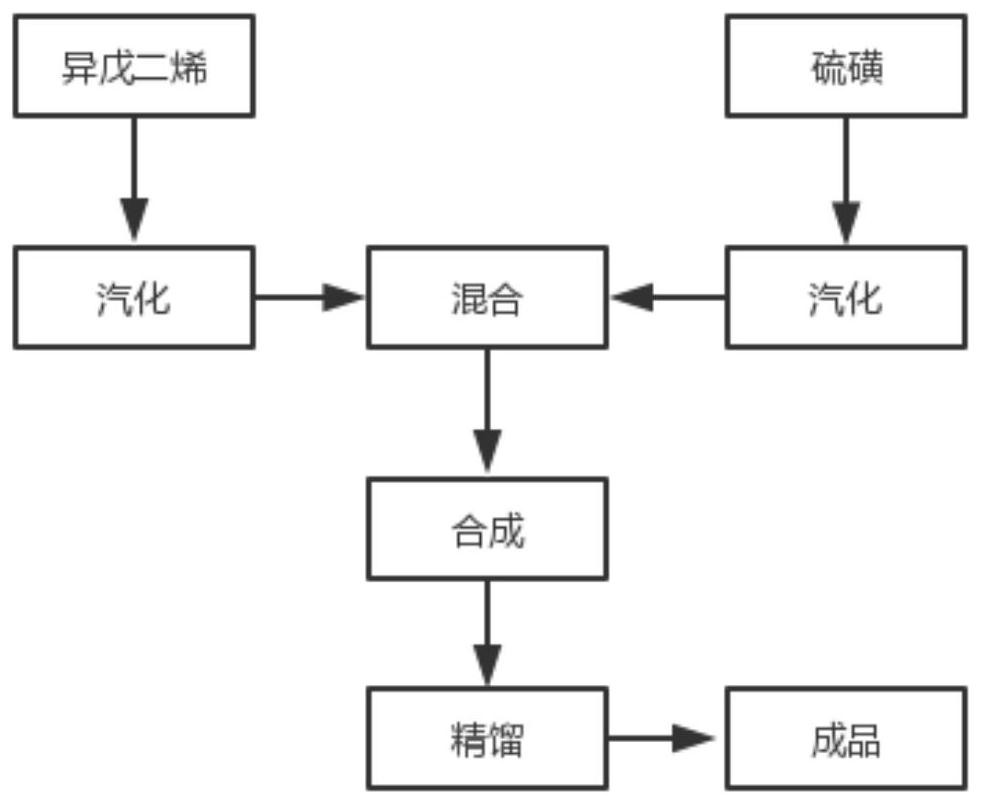

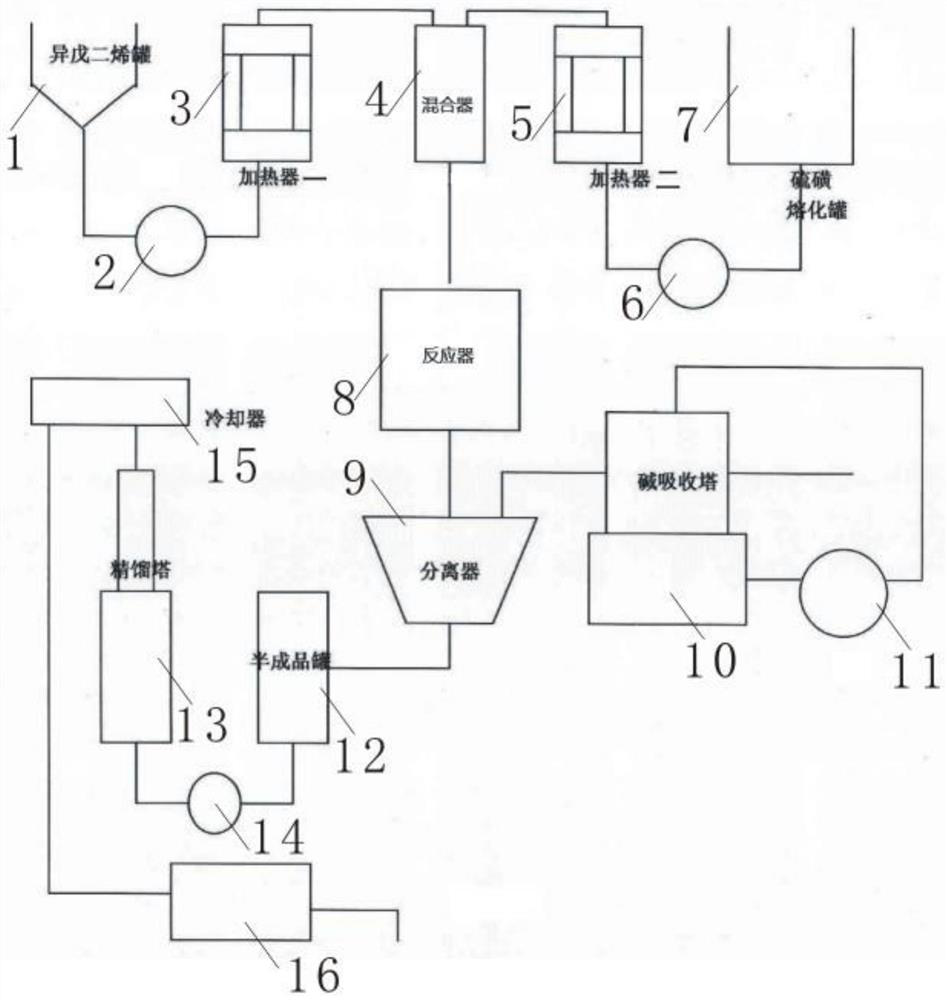

[0033] Production method of the present invention comprises the following steps:

[0034] (1) Put 150kg of sulfur and 234kg of isoprene into the sulfur liquefaction device and the isoprene liquefaction device respectively, and after liquefaction, send them to the vaporization device for vaporization. The temperature of the heater used to heat liquid isoprene into gaseous state is 50°C, and the heater keeps feeding and heating continuously. The temperature of the sulfur melting tank used to melt solid sulfur into liquid sulfur is 130°C, and the temperature of the heater used to heat liquid sulfur into vapor state sulfur is 450°C. The processor continues to feed and heat continuously;

[0035] (2) The vaporized isoprene and sulfur enter the mixer 4 at a fixed mass ratio of 1:1.5 for full vaporization and mixing, and the mixed gas enters the tubular reactor; the working parameters of the tubular reactor are: pressure 0.2Mpa, Temperature 300-320°C, vaporization and mixing reactio...

Embodiment 2

[0039] Production method of the present invention comprises the following steps:

[0040] (1) Put 145kg of sulfur and 230kg of isoprene into the sulfur liquefaction device and the isoprene liquefaction device respectively, and after liquefaction, send them to the vaporization device for vaporization. The temperature of the heater used to heat liquid isoprene into gaseous state is 50°C, and the heater keeps feeding and heating continuously. The temperature of the sulfur melting tank used to melt solid sulfur into liquid sulfur is 130°C, and the temperature of the heater used to heat liquid sulfur into vapor state sulfur is 450°C. The processor continues to feed and heat continuously;

[0041] (2) The vaporized isoprene and sulfur enter the mixer 4 at a fixed mass ratio of 1:1.53 for full vaporization and mixing, and the mixed gas enters the tubular reactor; the working parameters of the tubular reactor are: pressure 0.3Mpa, Temperature 300-320°C, vaporization and mixing reacti...

Embodiment 3

[0045] Production method of the present invention comprises the following steps:

[0046](1) Put 148kg of sulfur and 240kg of isoprene into the sulfur liquefaction device and the isoprene liquefaction device respectively, and after liquefaction, send them to the vaporization device for vaporization. The temperature of the heater used to heat liquid isoprene into gaseous state is 50°C, and the heater keeps feeding and heating continuously. The temperature of the sulfur melting tank used to melt solid sulfur into liquid sulfur is 130°C, and the temperature of the heater used to heat liquid sulfur into vapor state sulfur is 450°C. The processor continues to feed and heat continuously;

[0047] (2) The vaporized isoprene and sulfur enter the mixer 4 at a fixed mass ratio of 1:1.56 for full vaporization and mixing, and the mixed gas enters the tubular reactor; the working parameters of the tubular reactor are: pressure 0.2Mpa, Temperature 300-320°C, vaporization and mixing reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com