Efficient-cleaning combined type grain cleaning machine

A combined, cleaning machine technology, applied in dryers, removing smoke and dust, cleaning methods and utensils, etc., can solve problems such as affecting the health of workers, low screening and cleaning efficiency, and poor grain cleaning effect, and achieves improved application. range, improve the cleaning effect, and protect the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

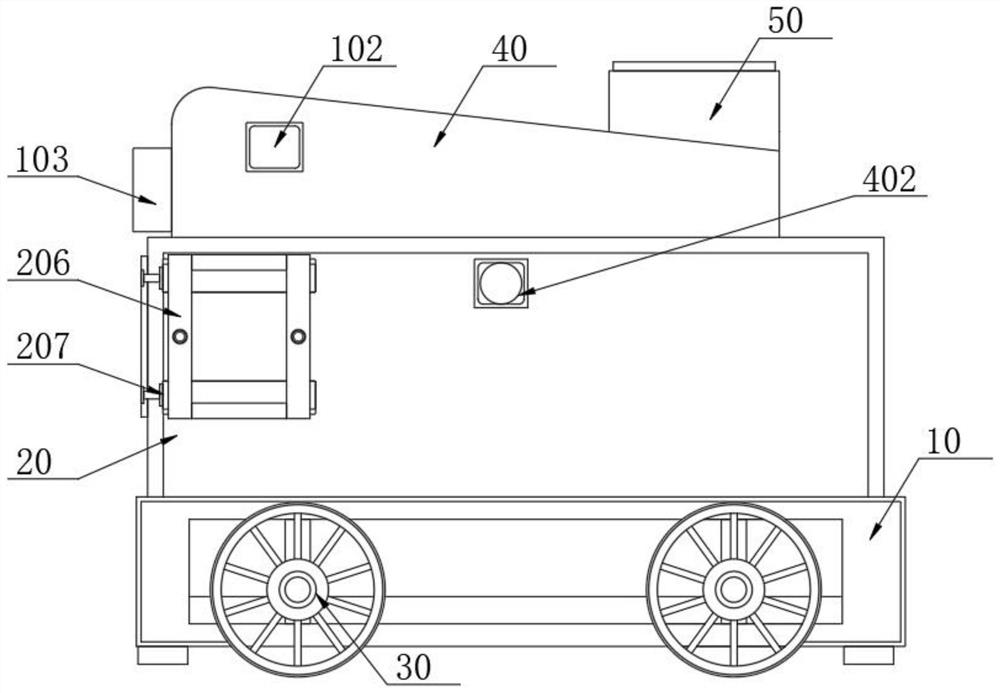

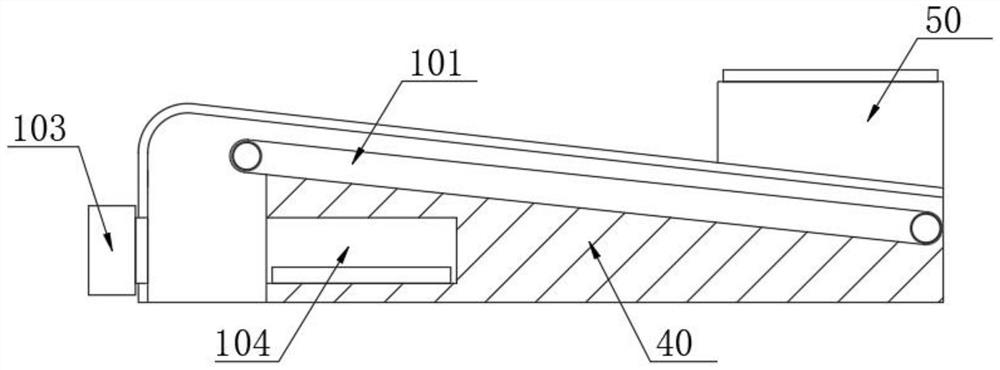

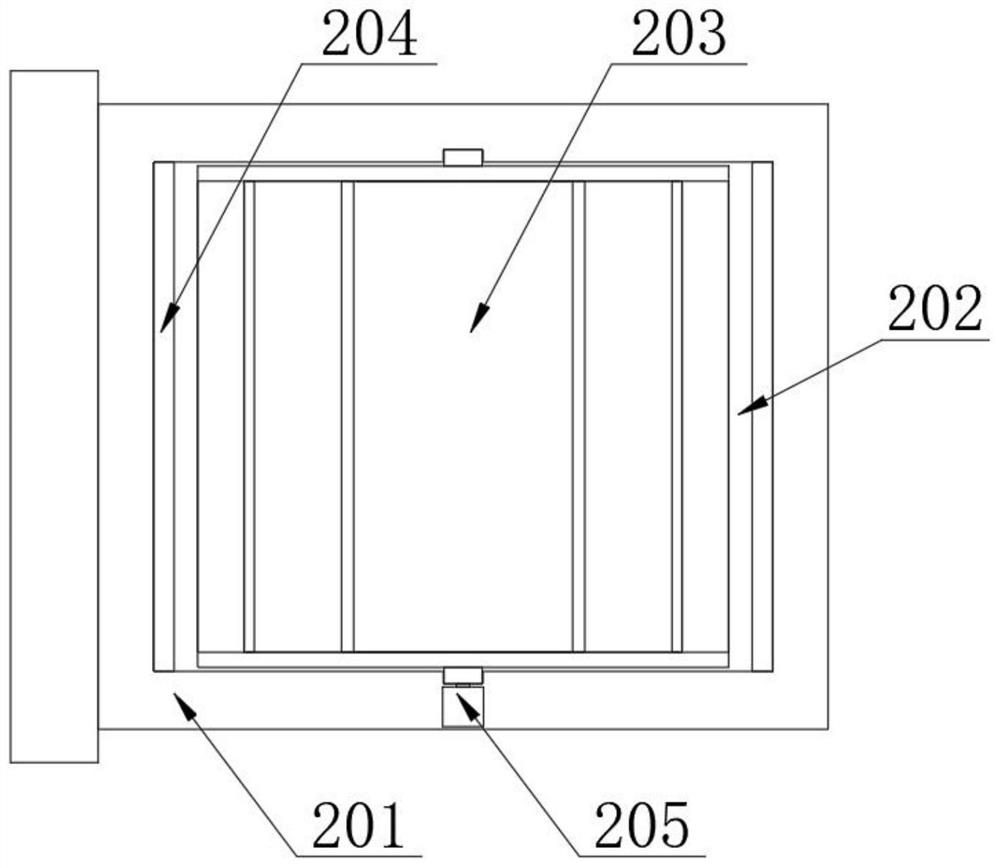

[0042] see Figure 1-7 As shown, a combined grain cleaning machine for efficient cleaning includes a frame 10 and a cleaning box 20, the cleaning box 20 is arranged inside the frame 10, and the front and back of the frame 10 are symmetrically provided with four moving wheels 30 , the top of the cleaning box 20 is provided with a feeding box 40, and the right side of the feeding box 40 top is provided with a feed hopper 50, the inside of the feeding box 40 is provided with a feeding mechanism, and the left side of the cleaning box 20 is provided with a first-level cleaning mechanism, And the bottom of the primary cleaning mechanism is provided with a sieving mechanism, the right side of the sieving mechanism is provided with a material guide mechanism, and one side of the material guiding mechanism is provided with a secondary cleaning mechanism, and the inside of the cleaning box 20 is located at the bottom of the secondary cleaning mechanism A discharge hopper 60 is arranged ...

Embodiment 2

[0051] see Figure 8 As shown, the secondary cleaning mechanism in the present invention also includes a cleaning pipe 508, and the bottom end of the cleaning pipe 508 communicates with the inside of the cleaning chamber 501, and two second screens 509 are arranged above the inside of the cleaning pipe 508, and the cleaning pipe The inside of 508 is provided with a second movable groove 510, and the second screen 509 located at the bottom is movably connected inside the second movable groove 510. Both sides of the cleaning pipe 508 are provided with second electric push rods 511, and two second One end of the electric push rod 511 is fixedly connected to both sides of the second screen 509 located below, and two second electric push rods 511 are used to drive the second screen 509 located below and the second screen 509 located above to generate misalignment , and then adjust the diameter of the sieve hole, when the grain is turned inside the cleaning bin 501, the remaining im...

Embodiment 3

[0053] see Figure 4 As shown, in the present invention, the right side of the inside of the cleaning box 20 is provided with a dust collection box 602, and the inside of the dust collection box 602 is provided with a dust collection bag 603, and the top of the dust collection box 602 is provided with a dust suction pump 604, and the dust suction The feed end of the pump 604 communicates with one end of the dust suction pipe 601, and the discharge end of the dust suction pump 604 communicates with the dust collection bag 603 inside the dust collection box 602. The dust pipe 601 is sent into the dust collection box 602, and the dust is collected in the dust collection box 602 through the dust collection bag 603, which effectively avoids the dust generated during the grain cleaning process from escaping and causing harm to the environment and human health. question.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com