Environment-friendly glass fiber production line

A glass fiber and production line technology, applied in glass production, glass manufacturing equipment, smoke and dust removal, etc., can solve the problems of low crushing degree, impact on crushing quality, and decline in production quality, so as to improve utilization rate, efficiency and quality and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

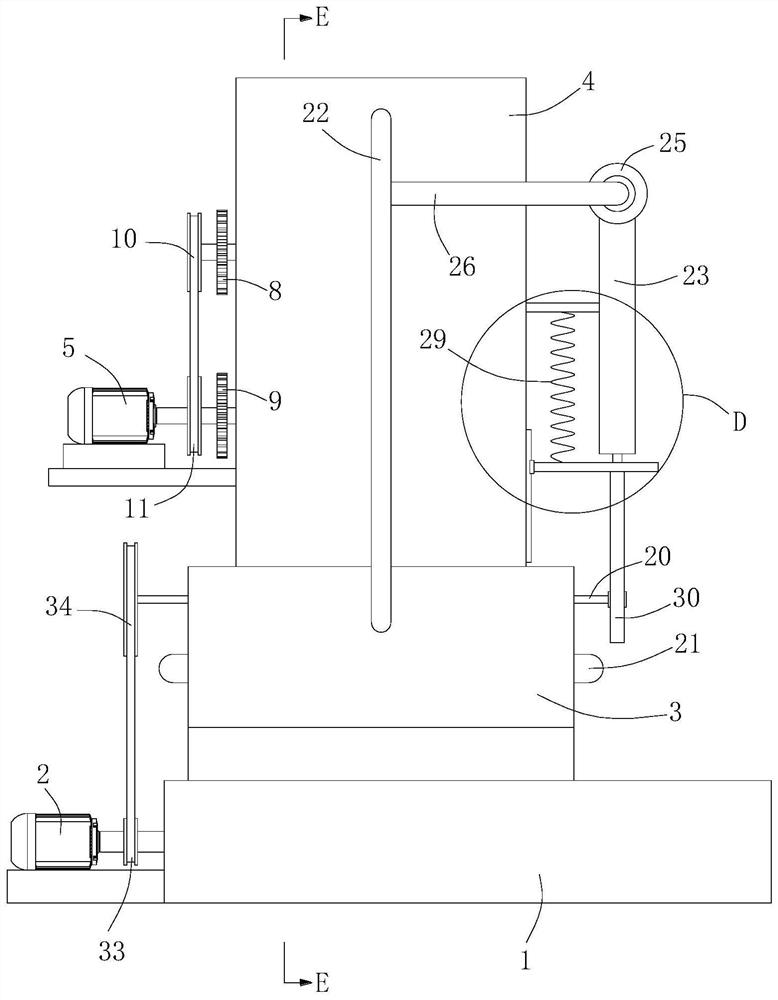

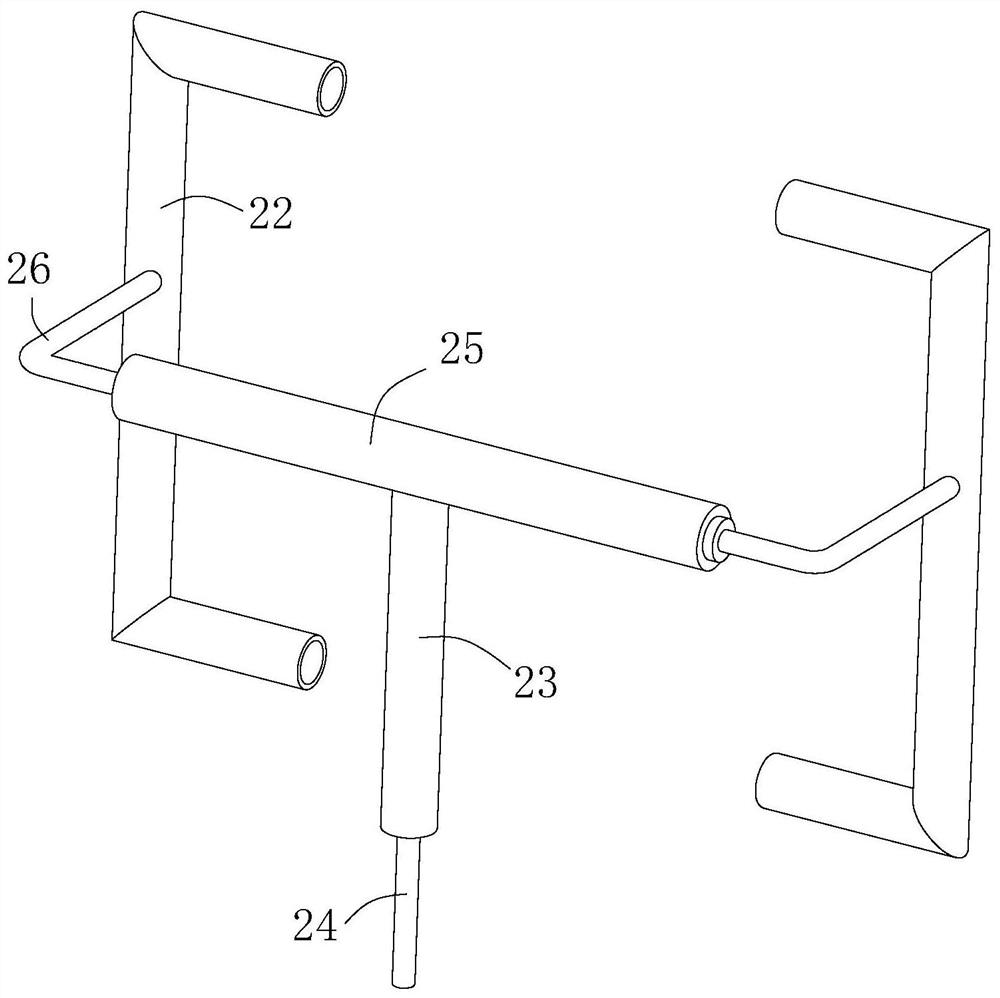

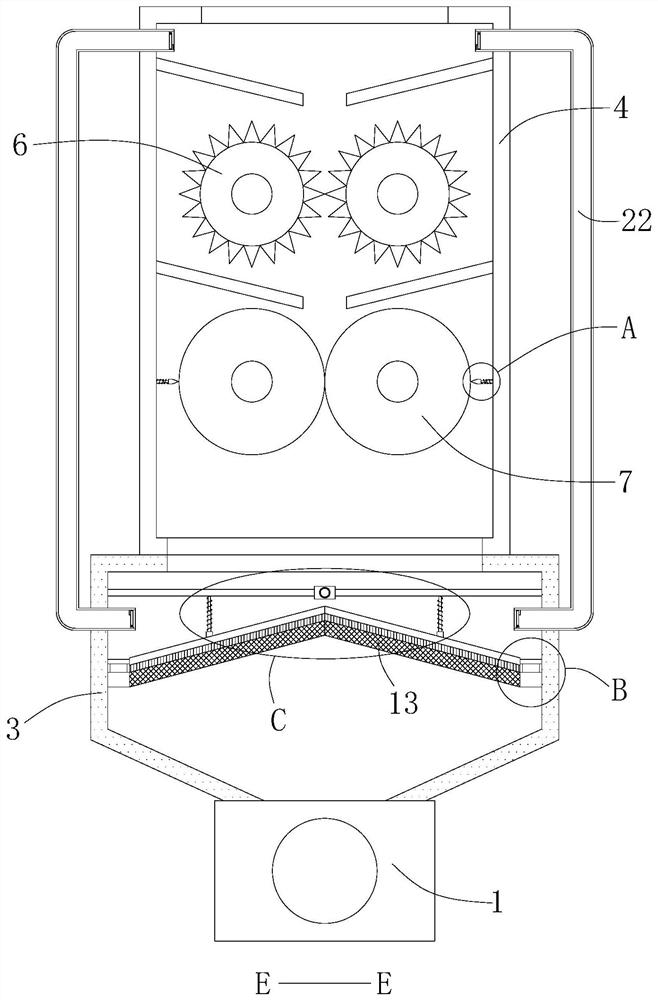

[0051] As an embodiment of the present invention, refer to figure 1 , figure 2 and Figure 8 , the one-way ash transport mechanism includes a fixed frame 28 fixedly installed on the side wall of the crushing box 4, a piston cylinder 23 is fixedly installed on the fixed frame 28, and the bottom end of the piston cylinder 23 is movably inserted with a piston rod 24. The lower end is fixedly equipped with a movable plate 27, and a back-moving spring 29 is connected between the movable plate 27 and the fixed frame 28, and a cam 30 is fixedly installed on the reciprocating screw 20, and the movable contact between the cam 30 and the movable plate 27, the piston cylinder 23 The top is connected with a transverse pipe 25, and the two ends of the transverse pipe 25 are respectively connected with connecting pipes 26 between the two dust-cleaning pipes 22, and the two ends of the dust-cleaning pipes 22 are respectively provided with one-way valves.

[0052] The one-way ash conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com