Cellulose gel layer modified loose nanofiltration membrane for high-flux dye separation as well as preparation method and application of cellulose gel layer modified loose nanofiltration membrane

A technology of cellulose gel and nanofiltration membrane, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of reduced separation performance of loose nanofiltration membranes, and achieve excellent hydrophilicity and antifouling properties , Simple operation, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of a loose nanofiltration membrane for high-throughput dye separation modified by a cellulose gel layer.

[0045] Specific steps are as follows:

[0046] 1) Preparation of ultrafiltration membrane base membrane: add dry polyvinylidene fluoride PVDF, PEG, LiCl and NMP into a three-necked flask in sequence, and mechanically stir for 10 hours at 65°C to obtain a uniform casting solution. After defoaming, use a film scraper to scrape the uniform casting solution on the glass plate, soak the glass plate in the coagulation solution, and prepare the polyvinylidene fluoride PVDF film (M-Pure) by the NIPS phase inversion method, that is Ultrafiltration membrane base membrane;

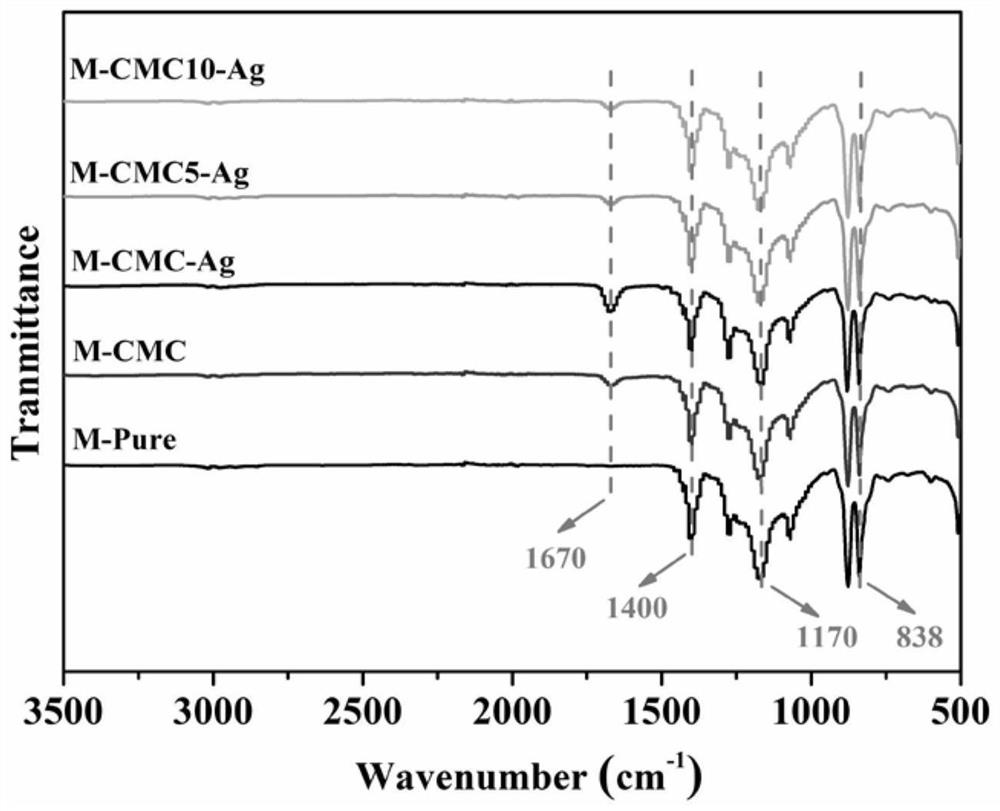

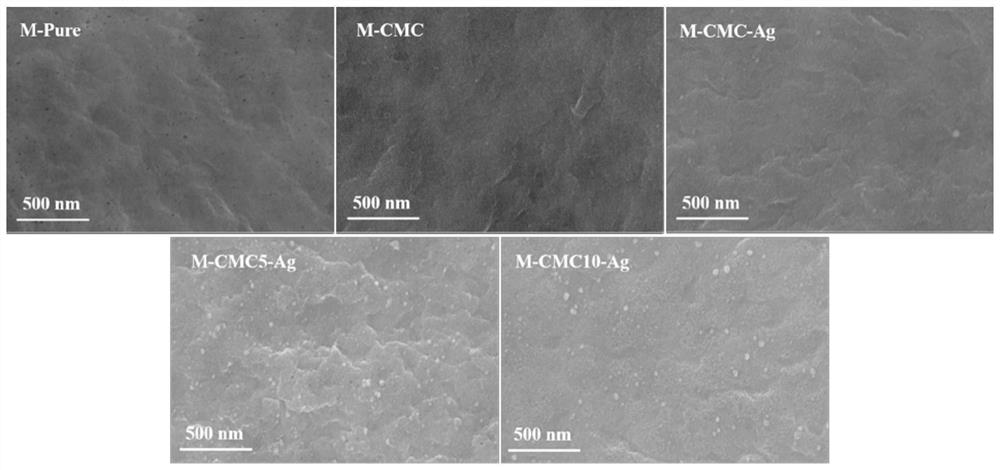

[0047] 2) dopamine and cellulose co-deposition modified ultrafiltration membrane base membrane: soak the PVDF membrane obtained in step 1) in 30mL Tris buffer containing 1g / L carboxymethylcellulose CMC and 1g / L dopamine DA, Shake in a shaker at a constant speed for 2 hours to carr...

Embodiment 2

[0051] Example 2: Preparation of a loose nanofiltration membrane for high-throughput dye separation modified by a cellulose gel layer.

[0052] Specific steps are as follows:

[0053] 1) Preparation of ultrafiltration membrane base membrane: add dry polyvinylidene fluoride PVDF, PEG, LiCl and NMP into a three-necked flask in sequence, and mechanically stir for 10 hours at 65°C to obtain a uniform casting solution. After defoaming, use a film scraper to scrape the uniform casting solution on the glass plate, soak the glass plate in the coagulation solution, and prepare the polyvinylidene fluoride PVDF film (M-Pure) by the NIPS phase inversion method, that is Ultrafiltration membrane base membrane;

[0054] 2) dopamine and cellulose co-deposition modified ultrafiltration membrane base membrane: soak the PVDF membrane obtained in step 1) in 30mL Tris buffer containing 1g / L carboxymethylcellulose CMC and 1g / L dopamine DA, Shake in a shaker at a constant speed for 2 hours to carr...

Embodiment 3

[0058] Example 3: Preparation of a loose nanofiltration membrane for high-throughput dye separation modified by a cellulose gel layer.

[0059] Specific steps are as follows:

[0060] 1) Preparation of ultrafiltration membrane base membrane: add dry polyvinylidene fluoride PVDF, PEG, LiCl and NMP into a three-necked flask in sequence, and mechanically stir for 10 hours at 65°C to obtain a uniform casting solution. After defoaming, use a film scraper to scrape the uniform casting solution on the glass plate, soak the glass plate in the coagulation solution, and prepare the polyvinylidene fluoride PVDF film (M-Pure) by the NIPS phase inversion method, that is Ultrafiltration membrane base membrane;

[0061] 2) dopamine and cellulose co-deposition modified ultrafiltration membrane base membrane: soak the PVDF membrane obtained in step 1) in 30mL Tris buffer containing 1g / L carboxymethylcellulose CMC and 1g / L dopamine DA, Shake in a shaker at a constant speed for 2 hours to carr...

PUM

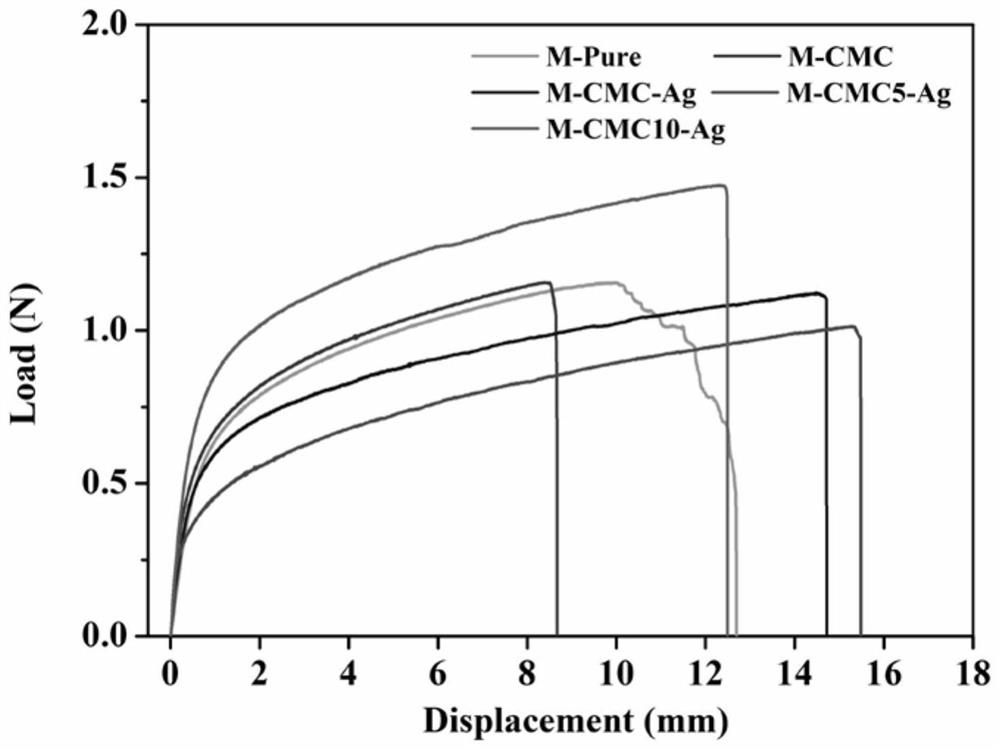

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com