Safe dust removal and collection device for overspray powder of spray-formed aluminum alloy

A technology of spray forming and collecting device, applied in the field of cleaning powder, can solve the problems of easy oxidation of powder, easy formation of dust or dust cloud, hidden danger of large dust explosion, etc., so as to improve production safety, prevent powder oxidation, and reduce process cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

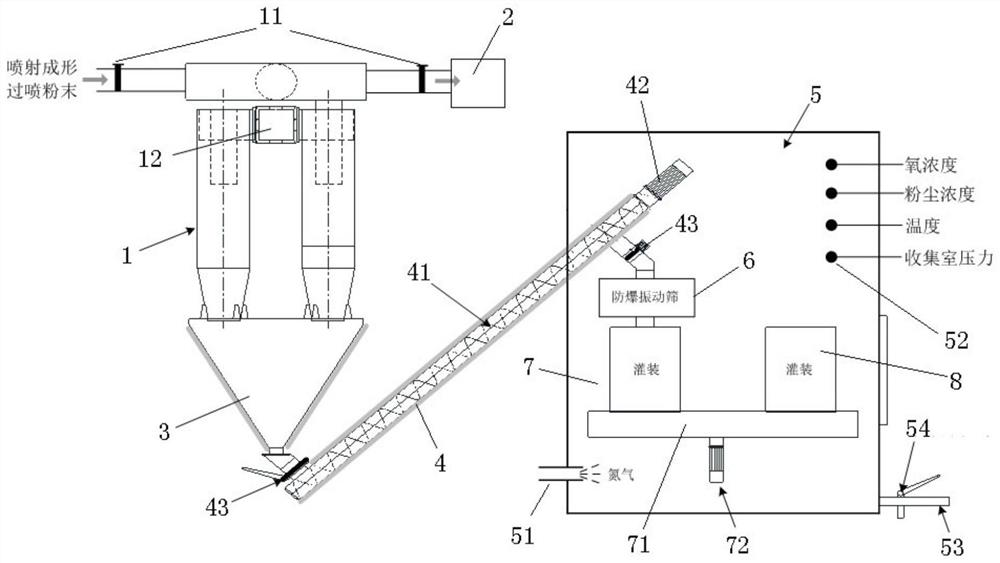

[0023] A spray-formed aluminum alloy overspray powder safety dust removal and collection device in this embodiment includes an overspray powder dust removal structure, a transfer structure and a dust collection structure. The overspray powder dust removal structure adopts a two-stage dust removal method, and the first-stage dust collector 1 is Cyclone separation type dust collector, the secondary dust collector 2 is a wet dust collector or bag dust collector, combined with the explosion-proof isolation valve 11, explosion vent 12 and the monitoring system installed in the primary dust collector 1 to achieve the safety of overspray powder dust removal and meet emission standards. Among them, 95% of the powder settles into the ash hopper 3 when passing through the cyclone separator; the secondary dust collector 2 performs dust removal treatment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com