Preparation method of camellia flower/leaf extract

A technology of leaf extract and camellia, which is applied in the field of preparation of camellia/leaf extract, can solve the problems of low extraction process efficiency and low active ingredients, and achieve the effect of avoiding the loss of active substances and rapid crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

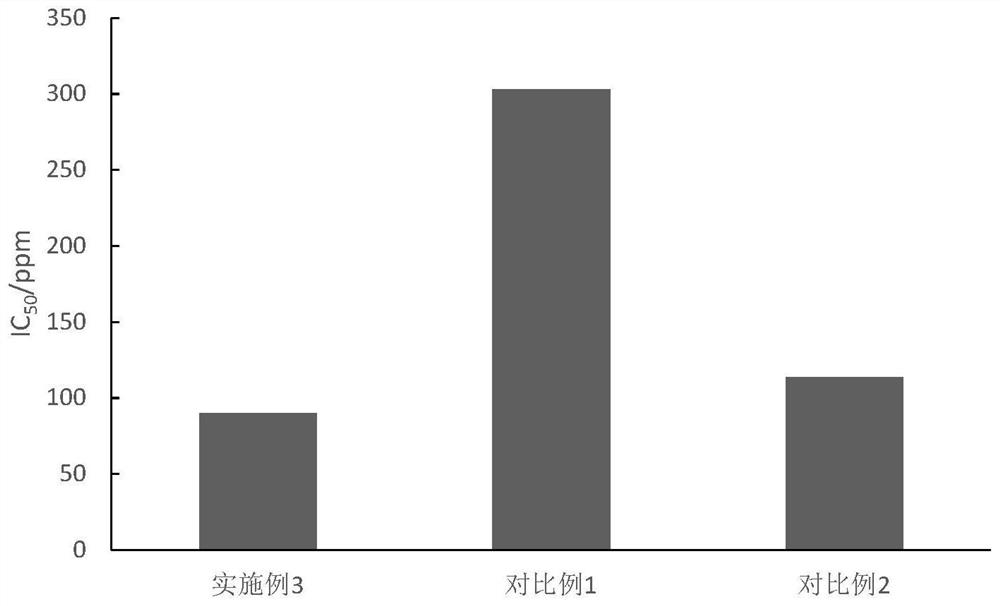

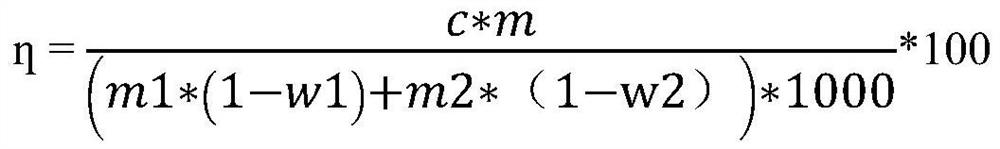

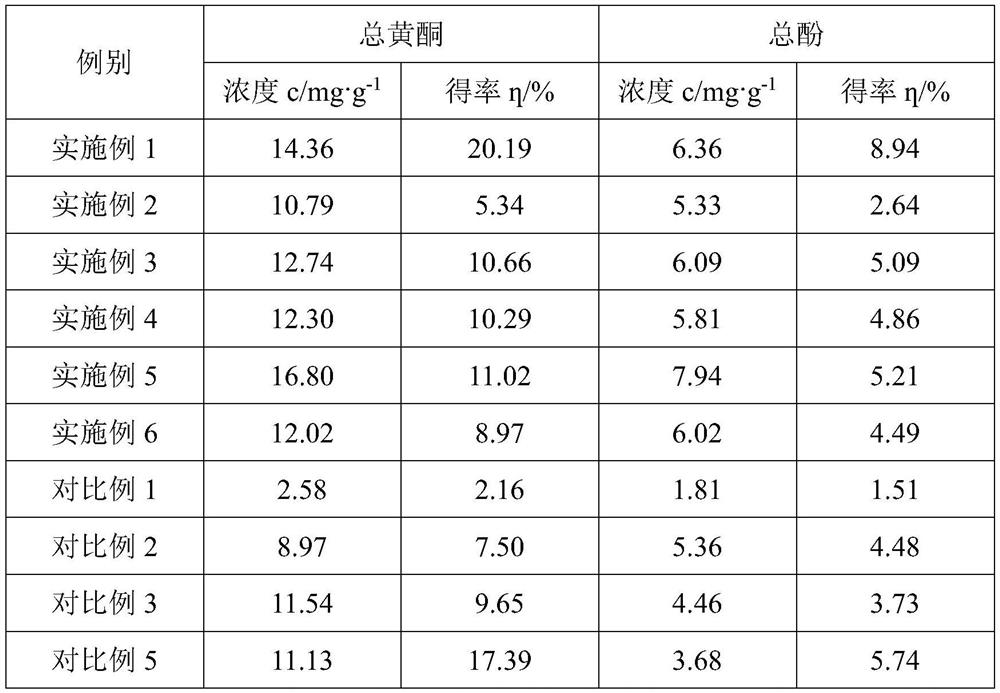

Examples

Embodiment 1

[0032] Get freshly picked camellias, wash with clear water, drain and cut into shreds to obtain fresh filaments. The moisture content measured by the oven method (105° C.) is 87.2%. Get 25g of filigree and put it into a blade-type crushing device, add 100g of ethanol aqueous solution with a volume fraction of 60%, turn on the device, and crush at a speed of 8000 rpm for 1 minute to obtain a flower particle dispersion. The resulting feed liquid was transferred to a beaker, and 100 g of ethanol aqueous solution with a volume fraction of 60% was added, and ultrasonically extracted at 50° C. with a power of 420 W for 1.5 hours. After the extraction was completed, the clarified filtrate and filter residue were obtained by suction filtration under reduced pressure. The filter residue was collected, and then 200 g of ethanol aqueous solution with a volume fraction of 60% was added. Ultrasonic extraction was performed at 50°C with a power of 420W for 1.5 hours. Filtrate under reduced ...

Embodiment 2

[0034] Get freshly picked camellia leaves, wash with clear water, drain and cut into shreds to obtain fresh shredded leaves. The moisture content measured by the oven method (105° C.) is 52.2%. Get 30g shredded leaves and put them into the blade-type crushing equipment, add 120g volume fraction of 60% ethanol aqueous solution, turn on the equipment, crush for 5 minutes at a speed of 8000 rpm, and obtain the fresh leaf particle dispersion. The resulting feed liquid was transferred to a beaker, and 120 g of ethanol aqueous solution with a volume fraction of 60% was added, and ultrasonically extracted at 50° C. with a power of 420 W for 1.5 hours. After the extraction was completed, the clarified filtrate and filter residue were obtained by suction filtration under reduced pressure. The filter residue was collected, and then 240 g of 60% ethanol aqueous solution was added, and ultrasonic extraction was performed at 50° C. with a power of 420 W for 1.5 hours. Filtrate under reduce...

Embodiment 3

[0036] Get 47.1g of the same fresh filaments as in Example 1, and prepare the flower particle dispersion with the same crushing condition; the weight of the 60% ethanol aqueous solution added in the crushing process is 188.4g.

[0037] Get 12.9g of fresh shredded leaves identical to Example 2, and prepare fresh leaf particle dispersions with the same crushing conditions. The weight of the 60% ethanol aqueous solution added during the crushing process was 51.6 g.

[0038]The above two dispersions were combined, and 240 g of ethanol aqueous solution with a volume fraction of 60% was added, and ultrasonically extracted at 50° C. with a power of 420 W for 1.5 hours. After the extraction was completed, the clarified filtrate and filter residue were obtained by suction filtration under reduced pressure. The filter residue was collected, and then 480 g of 60% ethanol aqueous solution was added, and ultrasonic extraction was performed at 50°C with a power of 420W for 1.5 hours. Sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com