Electric heating plate and preparation method thereof

A heating plate and electric heating technology, applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of unsatisfactory effect, heating efficiency, and affecting heating speed, etc., and achieve production cost Low, increased contact area, reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

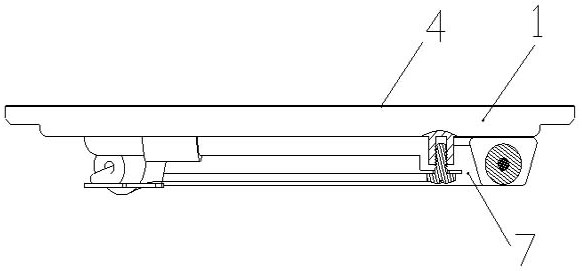

Method used

Image

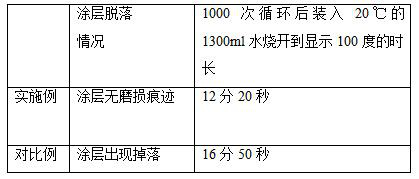

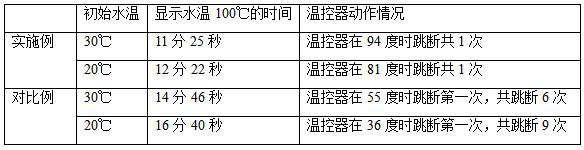

Examples

preparation example Construction

[0042] The preparation method of the electric heating heating plate of this embodiment comprises the following steps:

[0043] (1) Prepare spiral grooves with a depth of 0.1mm, a groove pitch of 0.6mm, and a groove width of 0.35mm on the first surface of the aluminum substrate for heating by turning, and the unevenness is less than 0.05mm;

[0044] (2) Preparation of thermal conductive coating mixture: 1) Sodium dodecyl sulfonate is first diluted with water according to the volume ratio of 1:500, 2) An appropriate amount of graphene is added to the diluted liquid for dispersion, 3) The dispersed Graphene liquid is added to the high-temperature resistant ink; 4) The adjusted graphene-containing ink is added with 800nm-sized copper powder, and the thermal conductive coating mixture is calculated by mass percentage: graphene 5%, copper powder 20% , high temperature resistant ink 81%, sodium dodecyl sulfonate + water 4%.

[0045] (3) Use screen printing to coat the thermally cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com