Evaporative condenser performance test method and system

An evaporative condenser and testing method technology, applied in the direction of thermal development of materials, etc., can solve the problems of insufficient capacity, confusion in industry selection, difficult selection and design, etc., and achieve the effect of reducing construction and operating costs, and data science.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

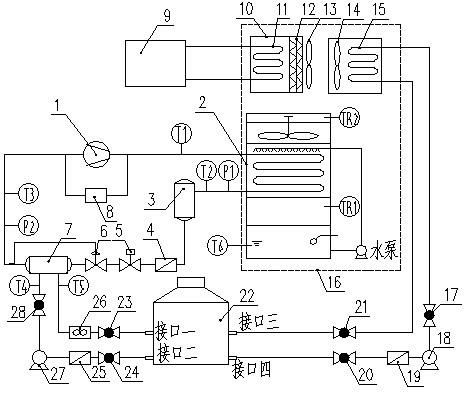

[0016] The present invention is an evaporative condenser performance testing method and system, and its specific implementation is as follows.

[0017] The exhaust port of the compressor 1 is connected to the air inlet of the heat exchange tube of the evaporative condenser 2, and the liquid outlet pipe of the heat exchange tube of the evaporative condenser 2 is connected to the inlet of the liquid receiver 3 , the outlet of the liquid reservoir 3 is connected to the inlet of the drier filter 4, the outlet of the drier filter 4 is connected to the inlet of the solenoid valve 5, and the outlet of the solenoid valve 5 is connected to the inlet of the throttle valve 6 The outlet of the throttle valve 6 is connected to the inlet of the refrigerant side of the evaporator 7, the outlet of the refrigerant side of the evaporator 7 is connected to the inlet of the compressor 1, and the outlet of the high and low pressure controller 8 The high-pressure end and the low-pressure end are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com