Quickly-assembled concrete-filled steel tube laminated shear wall staircase and installation method

A technology of superimposed shear walls and concrete-filled steel tubes, applied to stairs, walls, and stepped structures, can solve the problems of poor sound insulation effect of steel structure stairs, self-heavy weight of stairs with prefabricated concrete, and high requirements for hoisting equipment, and achieve energy saving Good effect, fast construction speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

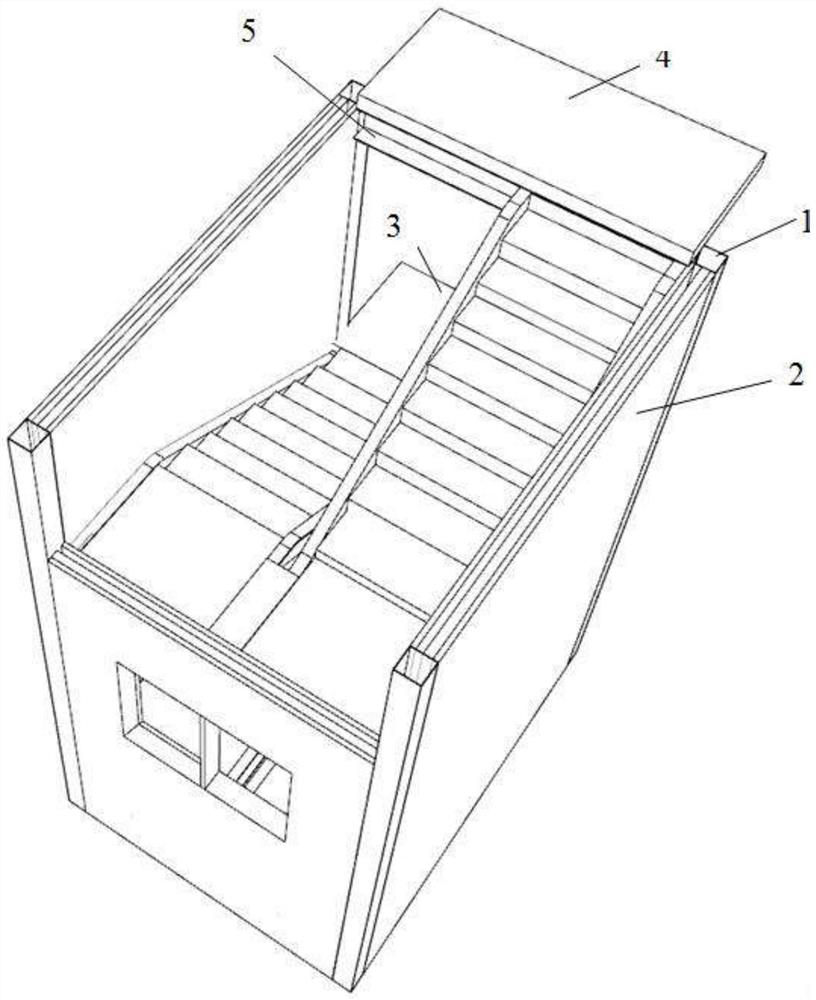

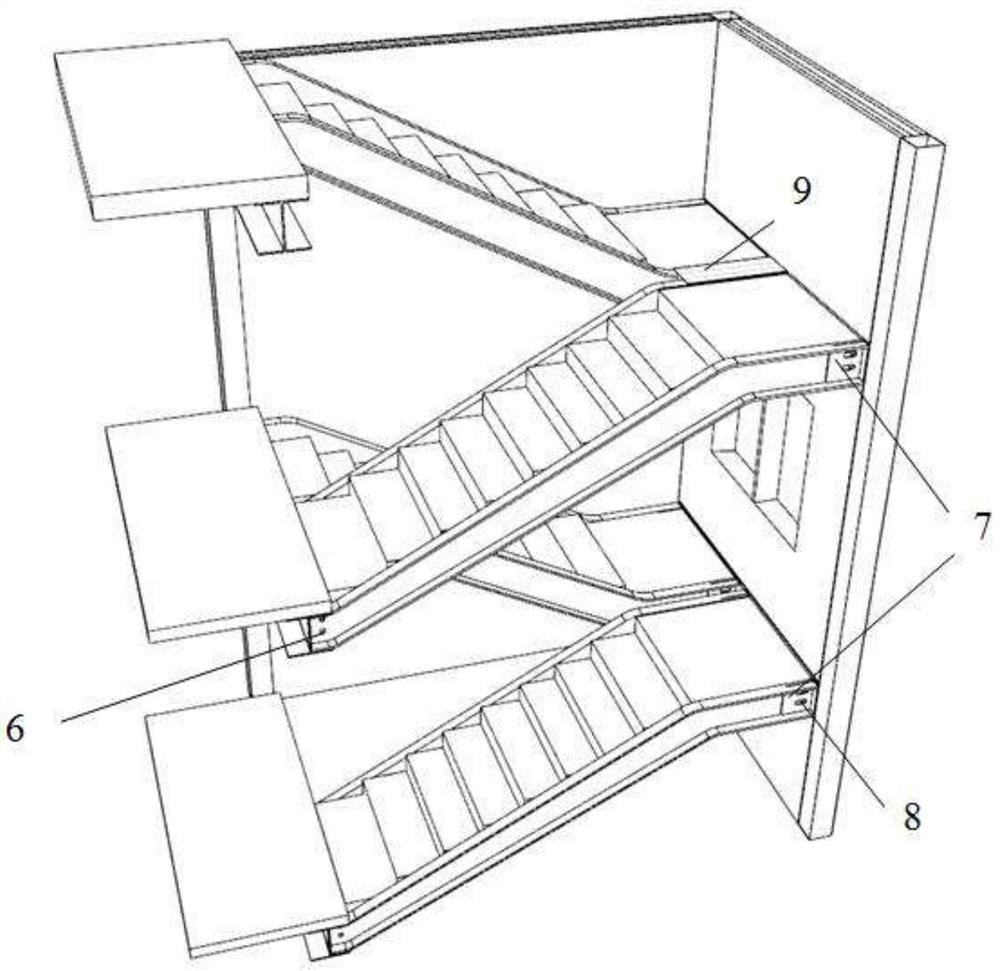

[0043] Such as Figure 1-3 As shown, the present embodiment provides a fast-installed steel pipe concrete laminated shear wall stairwell, including laminated shear walls, composite stairs 3, T-shaped cover plates 9 and frame beams 5, wherein the composite staircase 3 is from bottom to One end of the composite staircase 3 is connected to the floor slab 4 through the frame beam, and the other end is connected to the laminated shear wall through the connecting piece 7, and the composite staircase is provided with T-shaped cover plate 9.

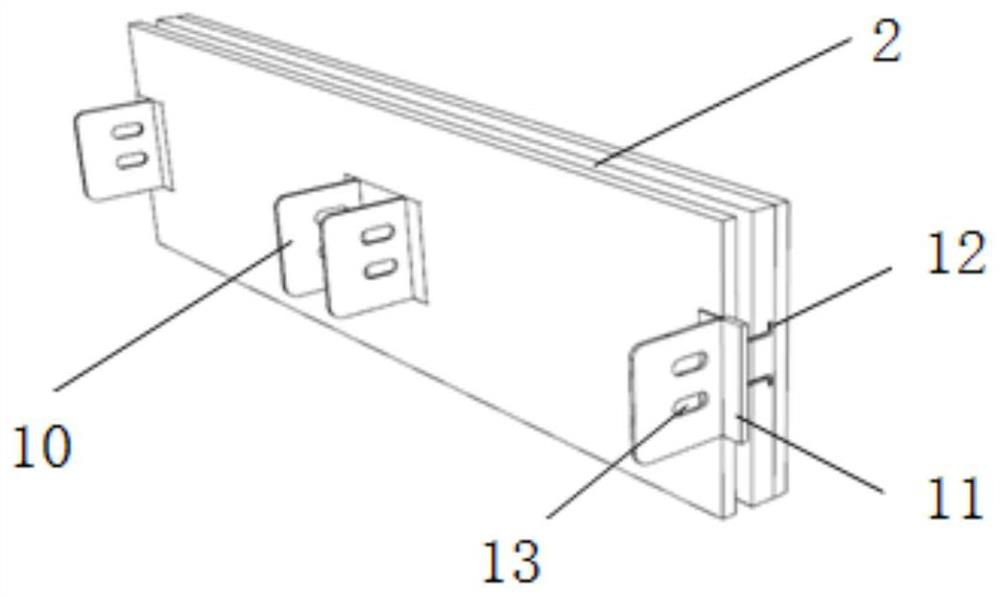

[0044] The laminated shear wall includes steel pipe 1 and shear wall 2. Steel pipe 1 is arranged on both sides of shear wall 2. The interior of shear wall 2 is a cavity. Steel pipes are used as edge restraint members on both sides to reduce wet work during use. volume and formwork support work.

[0045] The combined staircase comprises stair treads and a platform board, the stair treads and the platform board are integrally manufactured, and a...

Embodiment 2

[0060] A fast-installed concrete-filled steel pipe composite shear wall stairwell, the structure of which is as described in Example 1, the difference is that the outer side of the shear wall 2 is provided with an insulation layer and an outer leaf concrete plate to form a concrete-filled steel pipe with sandwich insulation The laminated shear wall has the same service life as the heat preservation and the structure. The cavities of the stair treads and platform slabs are filled with self-compacting concrete, and the cavity of the T-shaped cover plate 9 is filled with flexible material polystyrene foam particle mortar.

Embodiment 3

[0062] A fast-installed steel tube concrete laminated shear wall stairwell, the structure is as described in Embodiment 1, the difference is that the cavity of the T-shaped cover plate 9 is filled with flexible material polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com