Heat treatment machining device for hot work die steel

A technology of hot work die steel and processing equipment, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., and can solve problems such as cracking of hot work die steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

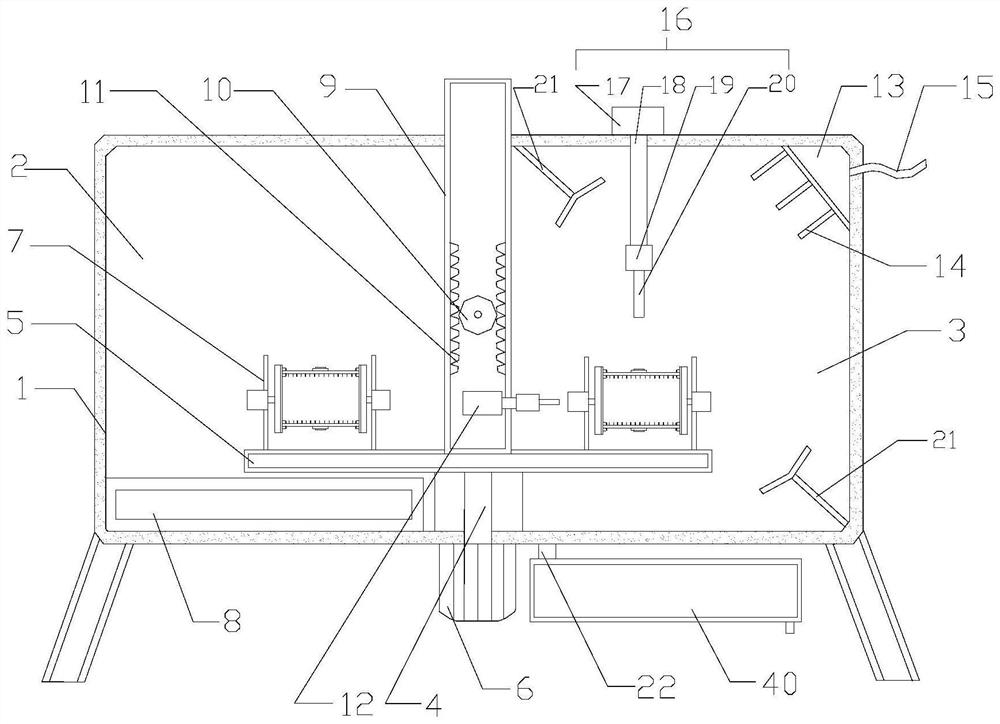

Method used

Image

Examples

Embodiment 1

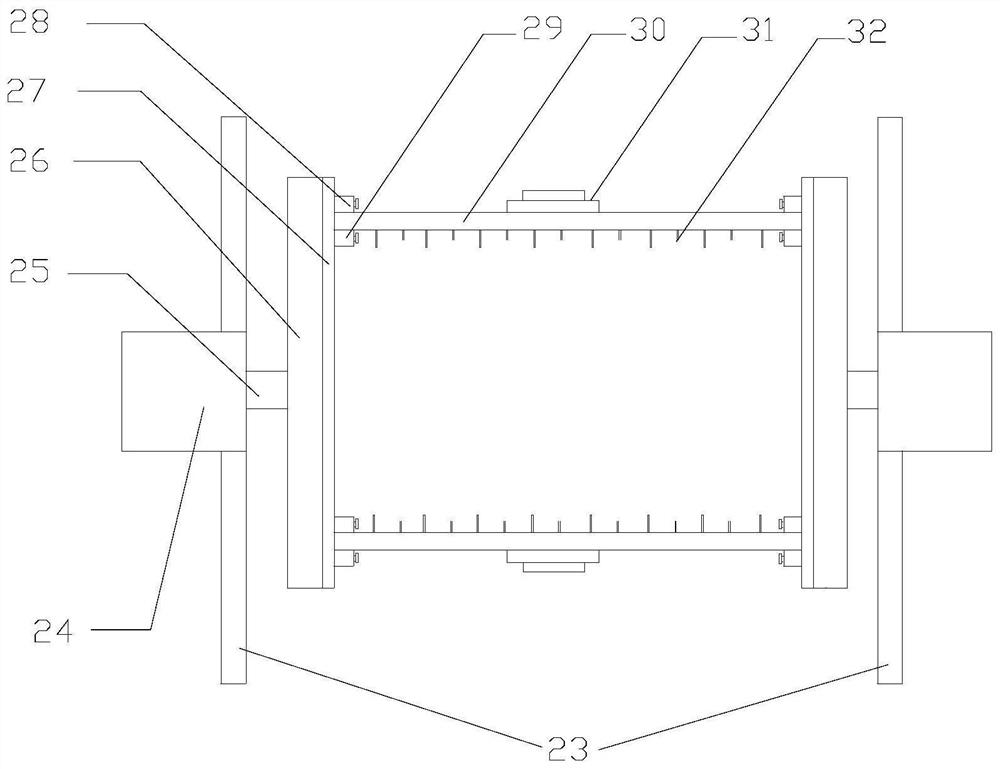

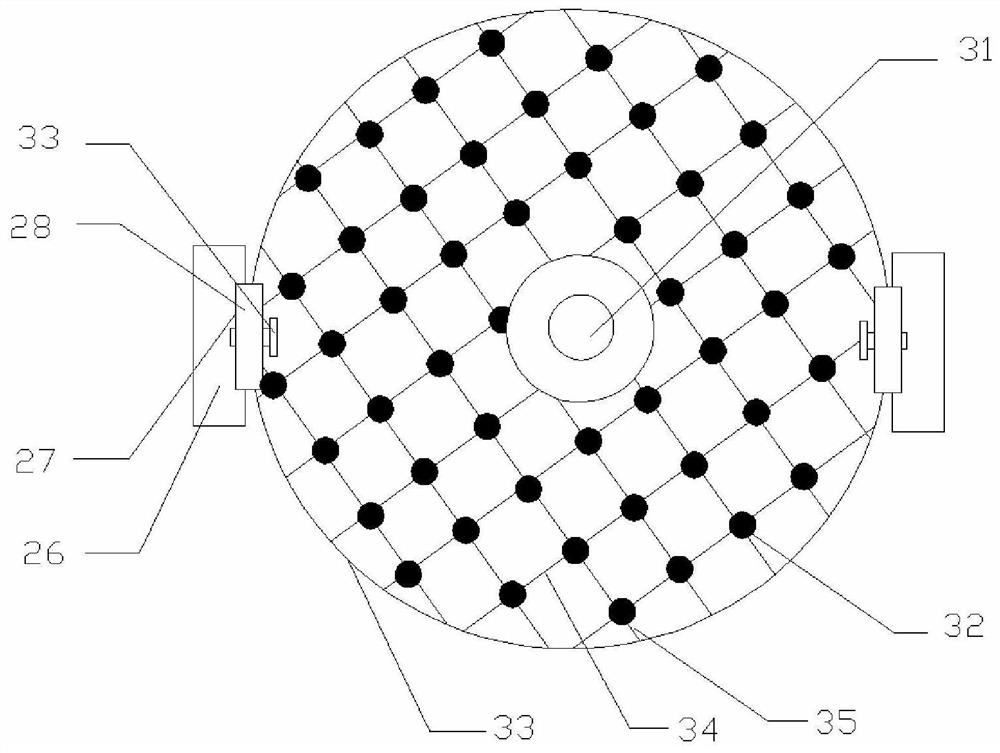

[0085] 1) Fix the hot work die steel between a pair of lifting plates 30, the thimble 32 can touch the hot work die steel (one of the lifting plates 30 and the hot work die steel are in clearance fit), open the compartment door 9, and start The platform rotation driving part 6 drives the rotating platform 5 so that the hot work die steel is located in the heat treatment chamber 2, and the isolation door 9 is closed to block the heat treatment chamber 2 and the cooling chamber 3;

[0086] 2) Start the preheating unit 8 to heat the hot work die steel aggressively, heat it to 680°C at a heating rate of 80°C / h and keep it for 10 hours, heat it to 850°C at a heating rate of 60°C / h and hold it for 10 hours, and then heat it at 50°C Heat up to 1030°C at a heating rate of / h and hold for 10h;

[0087] 3) Open the sealing door 9, start the platform rotation drive part 6 to drive the rotating platform 5 so that the hot work die steel is located in the cooling chamber 3, close the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com