On-line type pole piece bag-making and laminating process and bag-making and laminating production line thereof

A production line and pole piece technology, applied in sustainable manufacturing/processing, electrochemical generators, final product manufacturing, etc., can solve the problems of inability to guarantee the accuracy of positive and negative plates, inability to guarantee lamination efficiency, and time-consuming, etc. Achieve the effect of improving lamination efficiency, reducing short-circuit flammability, and improving battery safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

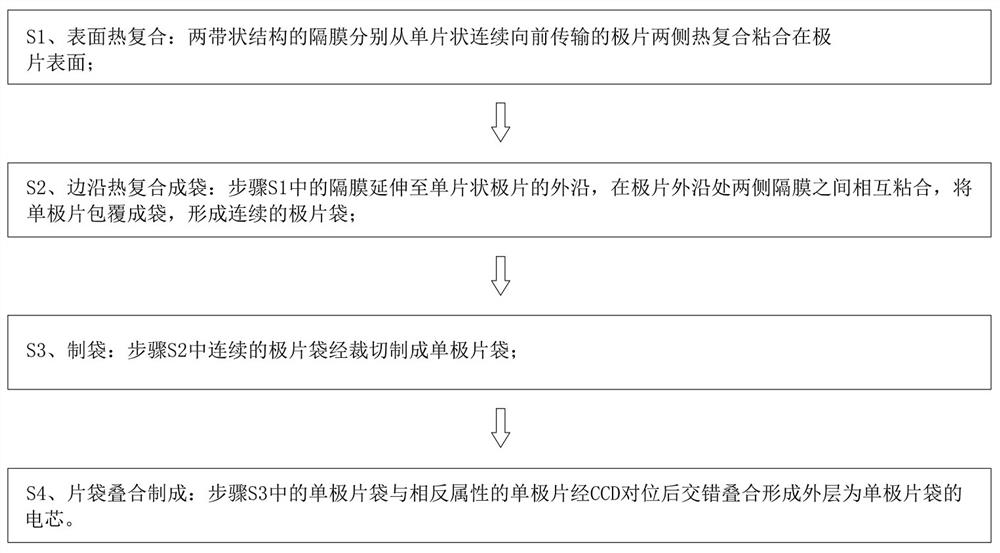

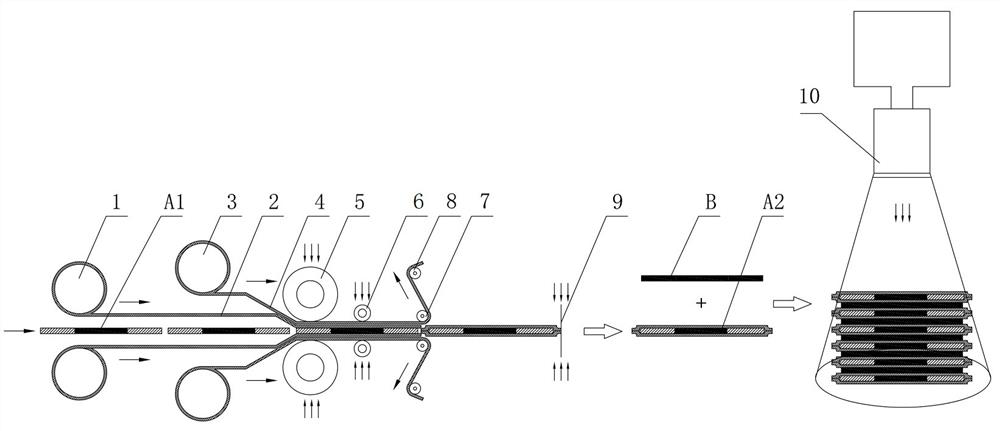

[0039] Embodiment 1: as Figure 1 to Figure 2 As shown, the technical solution adopted in Embodiment 1 of the present invention is as follows: an online pole piece bag-making and laminating process, including the following process steps:

[0040] S1. Surface thermal compounding: two strip-shaped diaphragms are thermally compounded and bonded to the surface of the pole piece from both sides of the pole piece that is continuously transmitted forward in a single piece;

[0041] S2. The edge is thermally compounded into a bag: the diaphragm in step S1 extends to the outer edge of the monolithic pole piece, and the diaphragms on both sides of the outer edge of the pole piece are bonded to each other, and the monopole piece is wrapped into a bag to form Continuous pole piece bag;

[0042] S3, bag making: the continuous pole piece bag in step S2 is cut into monopole piece bag;

[0043] S4. Lamination of sheet pockets: the monopolar sheet pockets in step S3 and the monopolar sheets ...

Embodiment 2

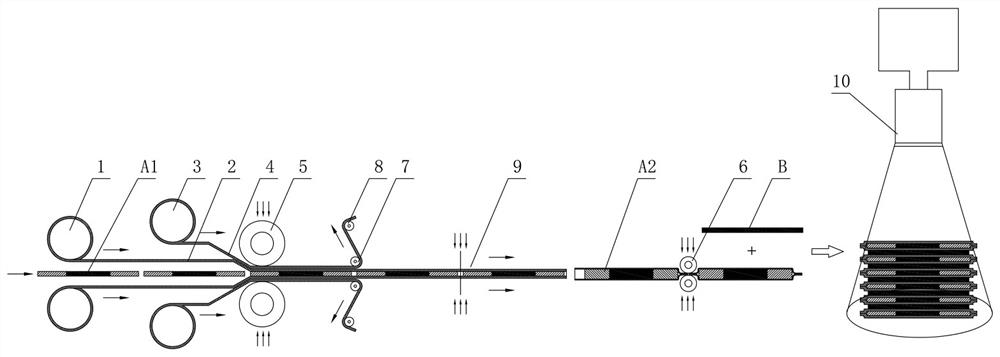

[0059] Embodiment 2: as image 3 As shown, it is the pole piece bag making and laminating production line of the online pole piece bag making and laminating process in Example 2 of the present invention. This embodiment has the same components as the production line in Example 1, and the difference is that the production line of this embodiment The sequence of the edge thermal compounding process and the bag making process is reversed, that is, after the surface thermal compounding process is completed, the diaphragm is cut along the middle of the distance between the adjacent two pole pieces. The diaphragms on the upper and lower sides of the outer edge are thermally compounded along the outer contour of the pole piece to form a bag. The process of Example 1 is to first carry out edge heat compounding and then cut the continuous diaphragm. Since the continuous diaphragm is tensioned and there is internal stress, it is possible that after the edge heat compounding, the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com