Construction method of multi-stirring hard-breaking anti-cracking pile machine

A construction method and pile driver technology, applied in drilling equipment and methods, excavation, sheet pile walls, etc., can solve the problems of single grouting mode, unfavorable pile formation, and unsystematic process, and achieve uniform mud and prevent local collapse. , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

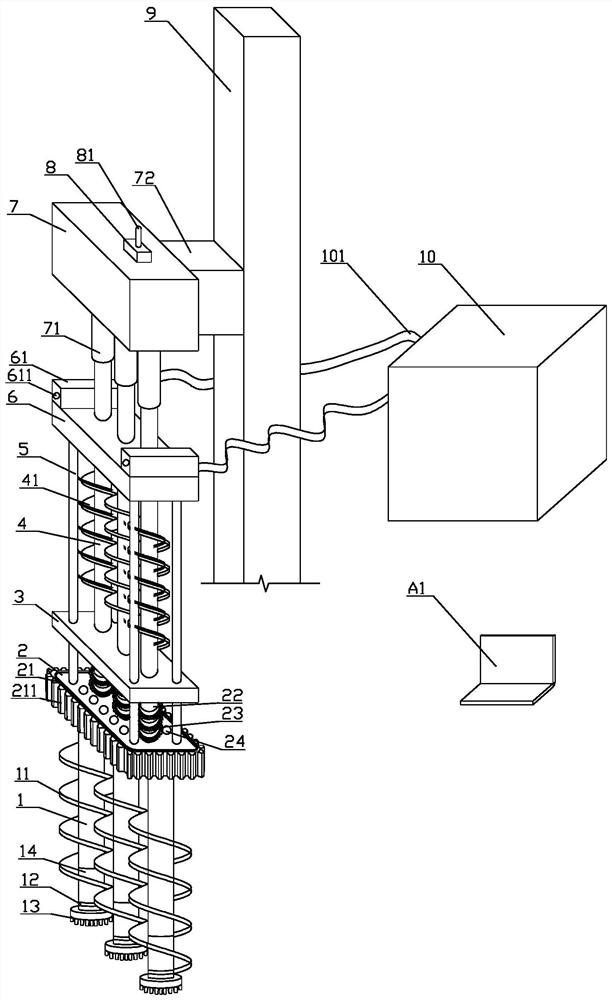

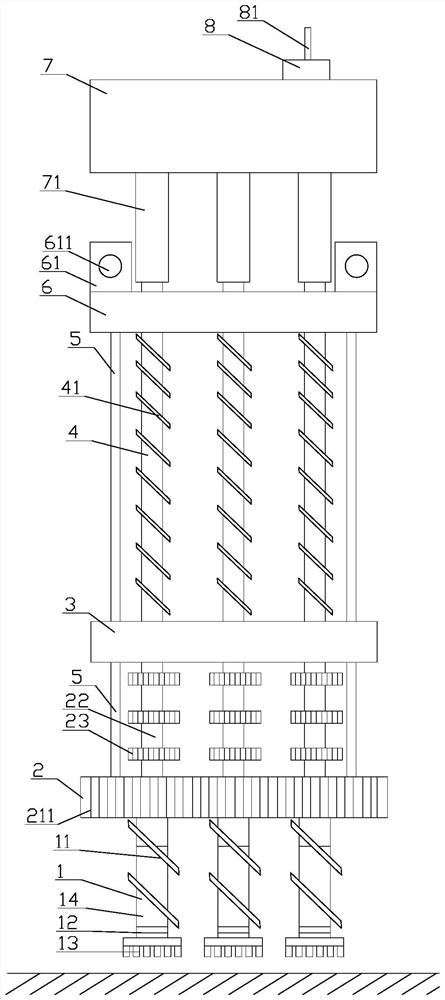

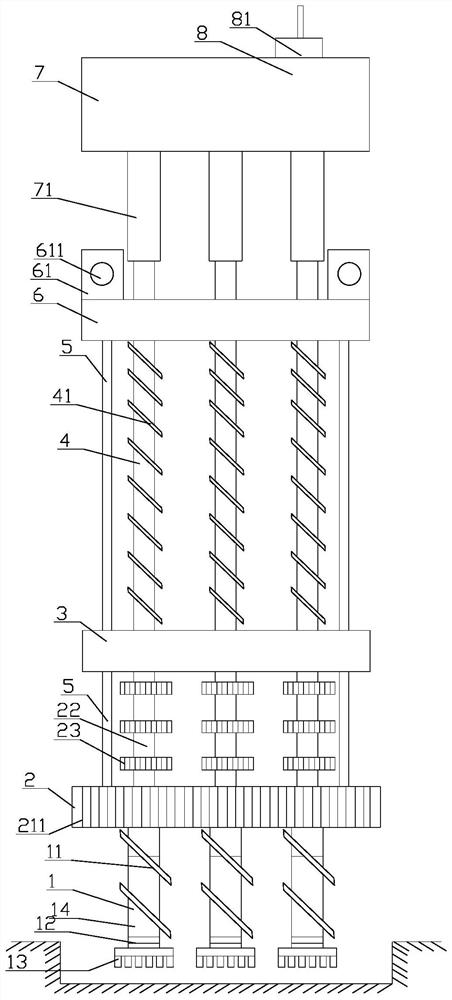

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] refer to Figure 1 to Figure 12 , a construction method for a multi-stirring firm-breaking anti-cracking pile driver, comprising the following steps:

[0042] (1) Transport the multi-stirring solid-breaking anti-cracking pile machine to the site, assemble it, and set it at the position where the pile is to be drilled;

[0043] (2) First dig a foundation pit with a depth of 0.5 at the position to be drilled into a pile, and the section of the foundation pit

[0044] The range is slightly larger than that of the first platform 2, and the size can be about 0.2m long;

[0045] (3) Set the first section drill pipe 1, the first section through the computer monitoring and control device A1 software

[0046] The rotating speed of the second section drill pipe 22 and the third section drill pipe 4, the rotational speed of the shield drilling bit 13 and the oil pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com